High-speed soft capsule forming machine

A technology of soft capsules and molding machines, which is applied in capsule transportation, household components, applications, etc. It can solve problems such as thinning defect rate, bursting, and narrowing of the joint area of capsules, so as to minimize defect rate and material loss, and prevent physical damage. Deterioration of properties, effect of minimizing injection position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

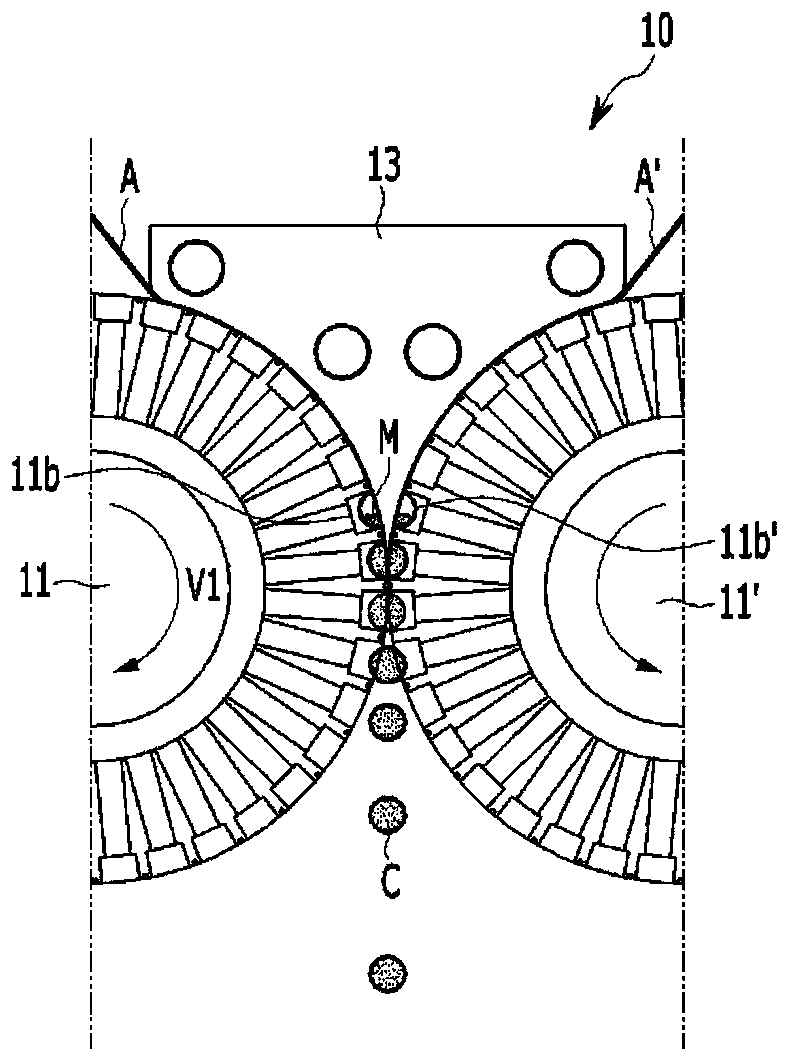

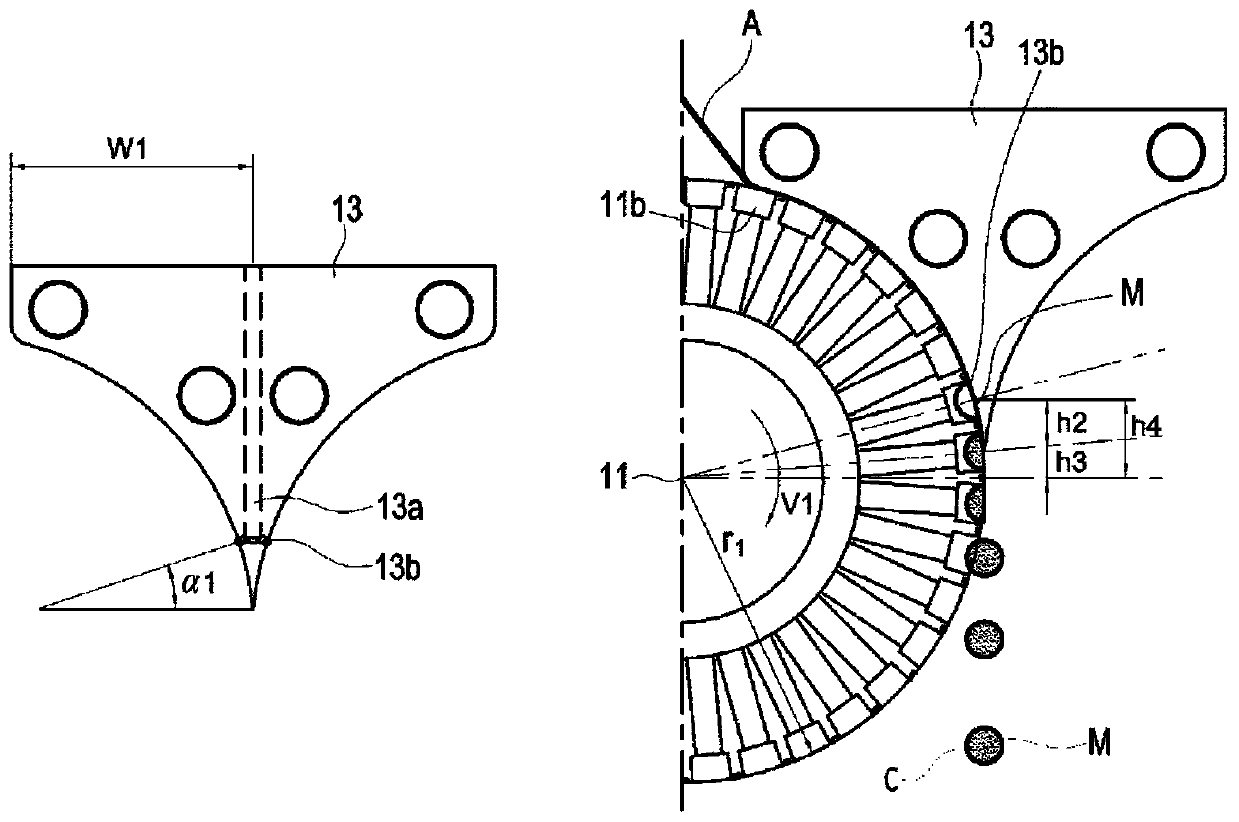

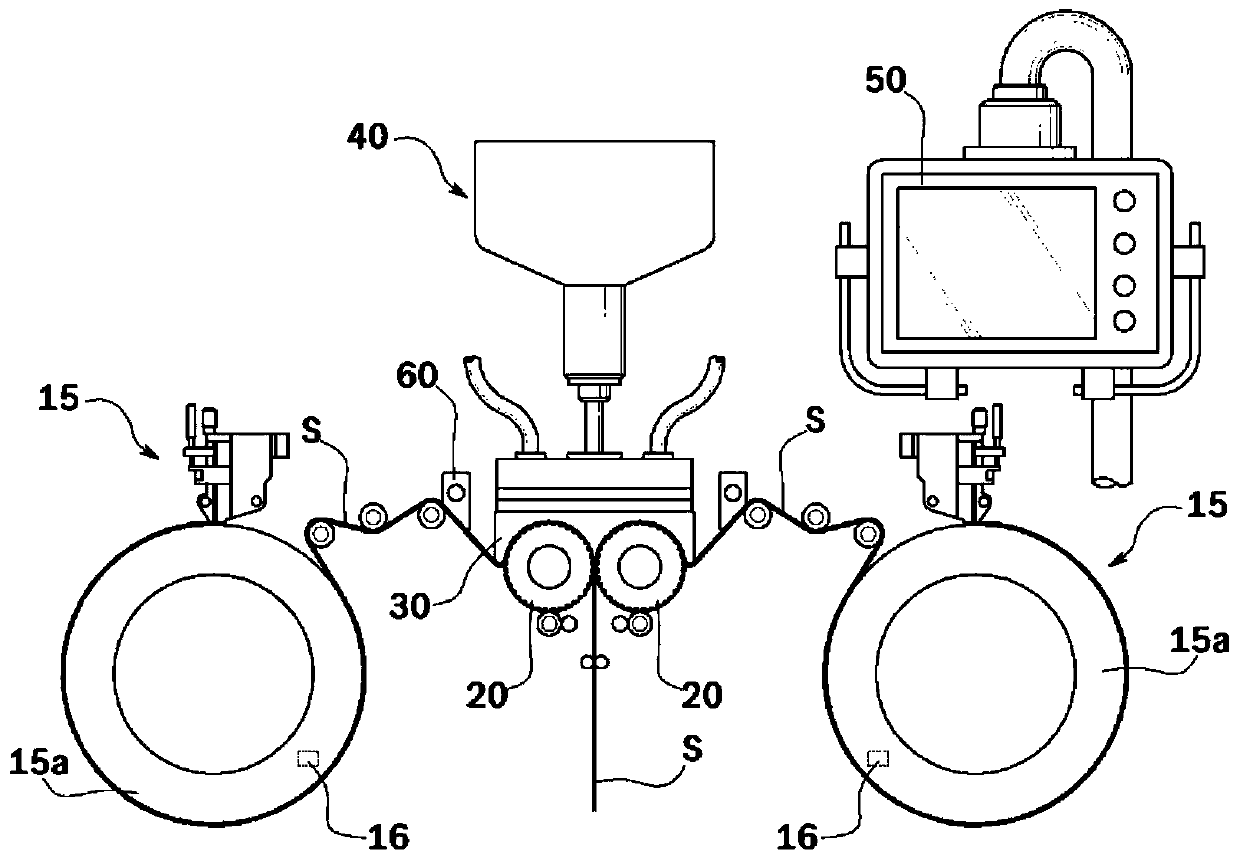

[0128] like Figure 12 to Figure 15 As shown, the high-speed soft capsule forming machine according to the second embodiment of the present invention includes a sheet forming part 15 , a pair of die rollers 20 , a wedge 30 , a liquid medicine supply part 40 , a controller 50 and a preheating part 60 .

[0129] That is, the gelatin sheet S formed into two thin films with a gelatin solution in the sheet forming part 15 is heat-sealed in the rotating pair of mold rolls 20 and wedges 30, and the chemical solution F supplied from the chemical solution supply part 40 is supplied at a predetermined rate. The soft capsules filled with the drug solution F in the gelatin sheets S are continuously prepared by periodically injecting them between the gelatin sheets S and cutting them into capsule shapes.

[0130] The sheet forming section 15 is a part for conveying and supplying the gelatin sheet S of the film after being continuously molded with a gelatin solution, and is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com