Flame Retardant Resin Composition And Molded Product

A technology of flame retardant resin and composition, applied in the field of flame retardant resin composition and molded products, can solve the problems of inability to complete physical properties and flame retardancy, low oil dependence, low environmental load, etc., and achieve low oil dependence. properties, prevention of deterioration of physical properties, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] The kraft lignin in Example 1 is contained in the cooking liquor (black liquor) discharged when pulp is produced by kraft pulping, wherein an aqueous sodium hydroxide solution and an aqueous sodium sulfide solution are brought into the cooking liquor. In Example 1, lignin base (370959), a reagent manufactured by Sigma-Aldrich Co. LLC., was used as the sulfate lignin.

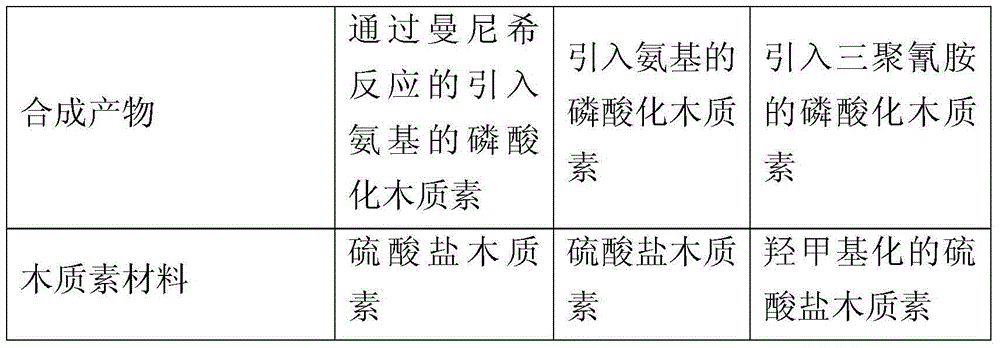

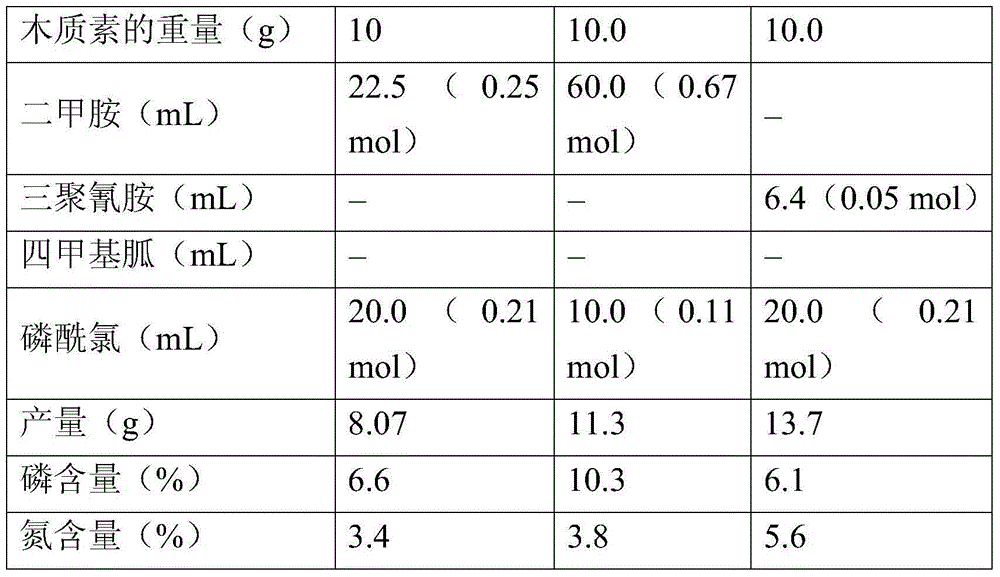

[0113]

[0114] Kraft lignin (10 g, lignin base, manufactured by Sigma-Aldrich Co., Ltd.) was dissolved to 80% by mass Alkanes (300mL) and acetic acid (30mL) mixed solution. Under stirring, 50% by mass of dimethylamine solution (22.5 mL, 0.25 mol) and 37% by mass of formamide solution (18.7 mL, 0.25 mol) were added thereto, followed by allowing to react in a 60°C water bath 4 hours. Thereafter, the resulting reaction solution was added dropwise to acetone to form a precipitate. The precipitate was filtered with suction and the residue was washed with water and then dried in a desiccator, whereby the ...

Embodiment 2)

[0137] Using the kraft lignin described in Example 1 as starting material the following reaction products were obtained.

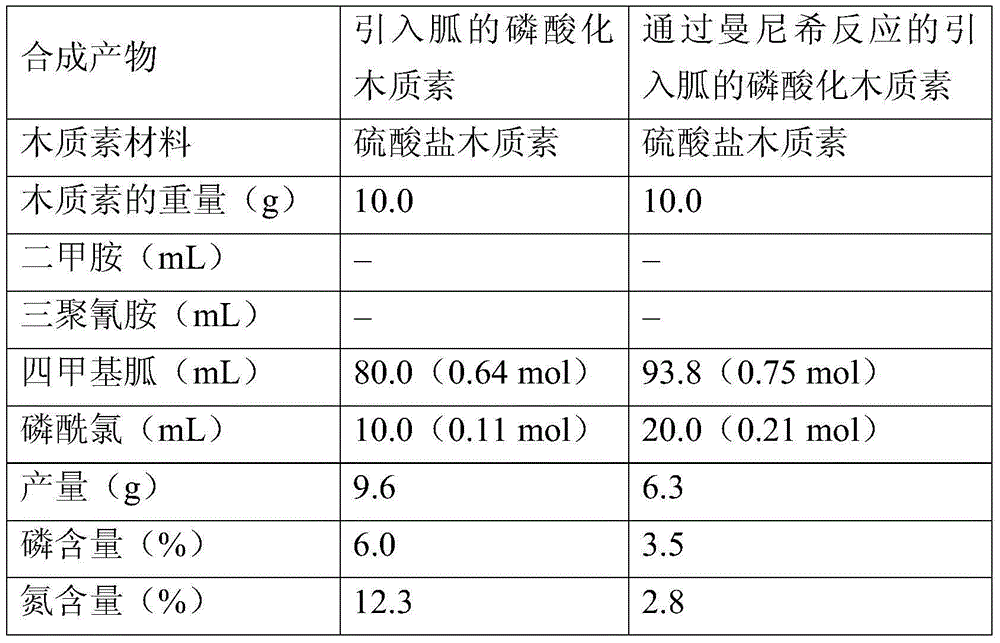

[0138]

[0139] Kraft lignin (10 g) was dissolved in pyridine (250 mL). Phosphorus oxychloride (10 mL, 0.11 mol) was added thereto under stirring. After 1 hour, a mixed solution of 50% by mass dimethylamine solution (60 mL, 0.67 mol) and pyridine (60 mL) was additionally added. After 1 hour, the resulting reaction solution was added dropwise to water to terminate the reaction, followed by centrifugation (11,000 rpm, 15 min). The obtained precipitate was repeatedly washed with acetone and air-dried in a fume hood, thereby obtaining a reaction product. The phosphorus content in the resulting reaction product was measured by the flask combustion method (titration method). The nitrogen content in the reaction product was measured by elemental analysis. The results are shown in Tables 1-1 and 1-2. It was confirmed that a nitrogen-containing phosphorylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com