Cotton candy machine heating in furnace end

A cotton candy, internal heating technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problem of difficulty in selecting heat-conducting materials for sugar temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

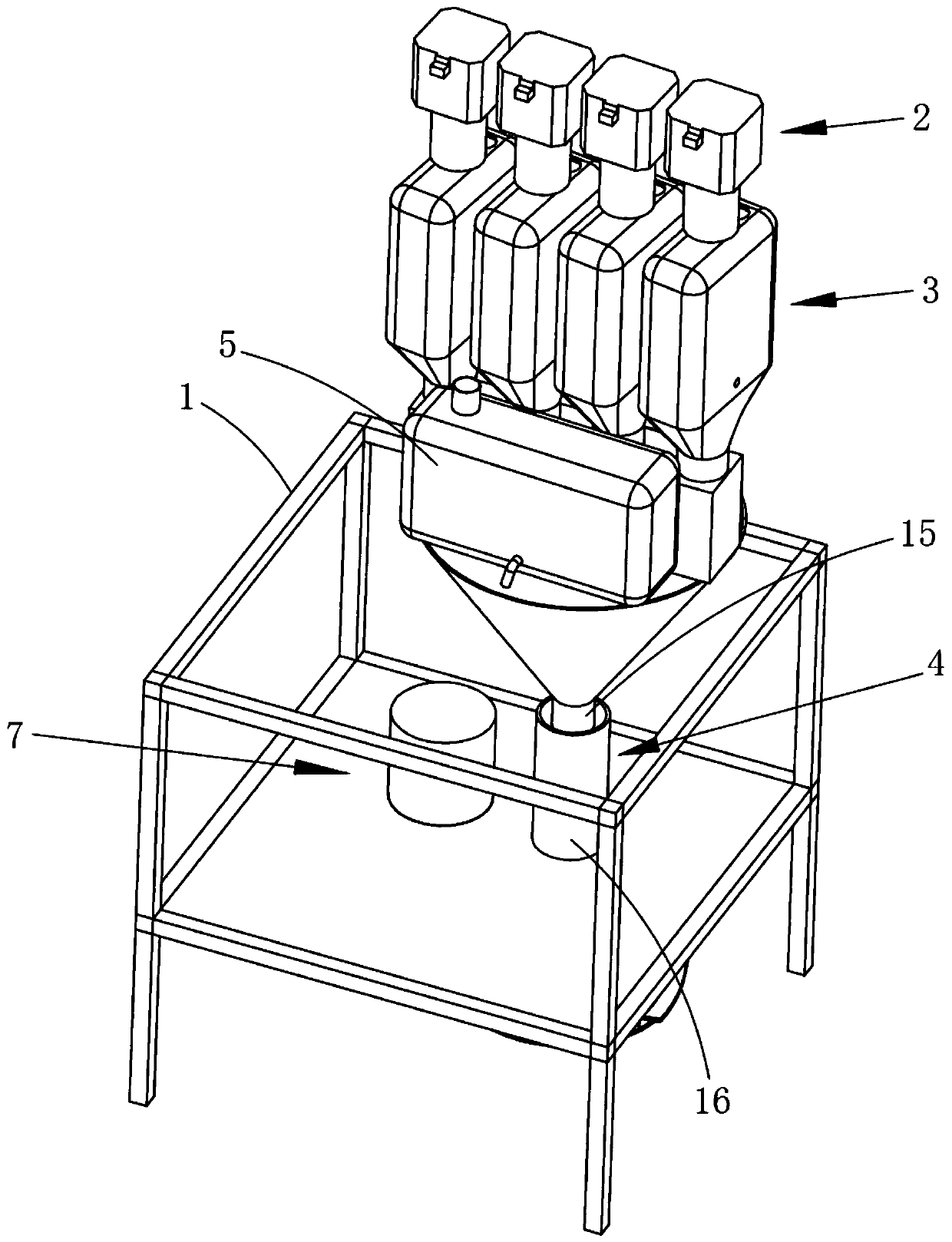

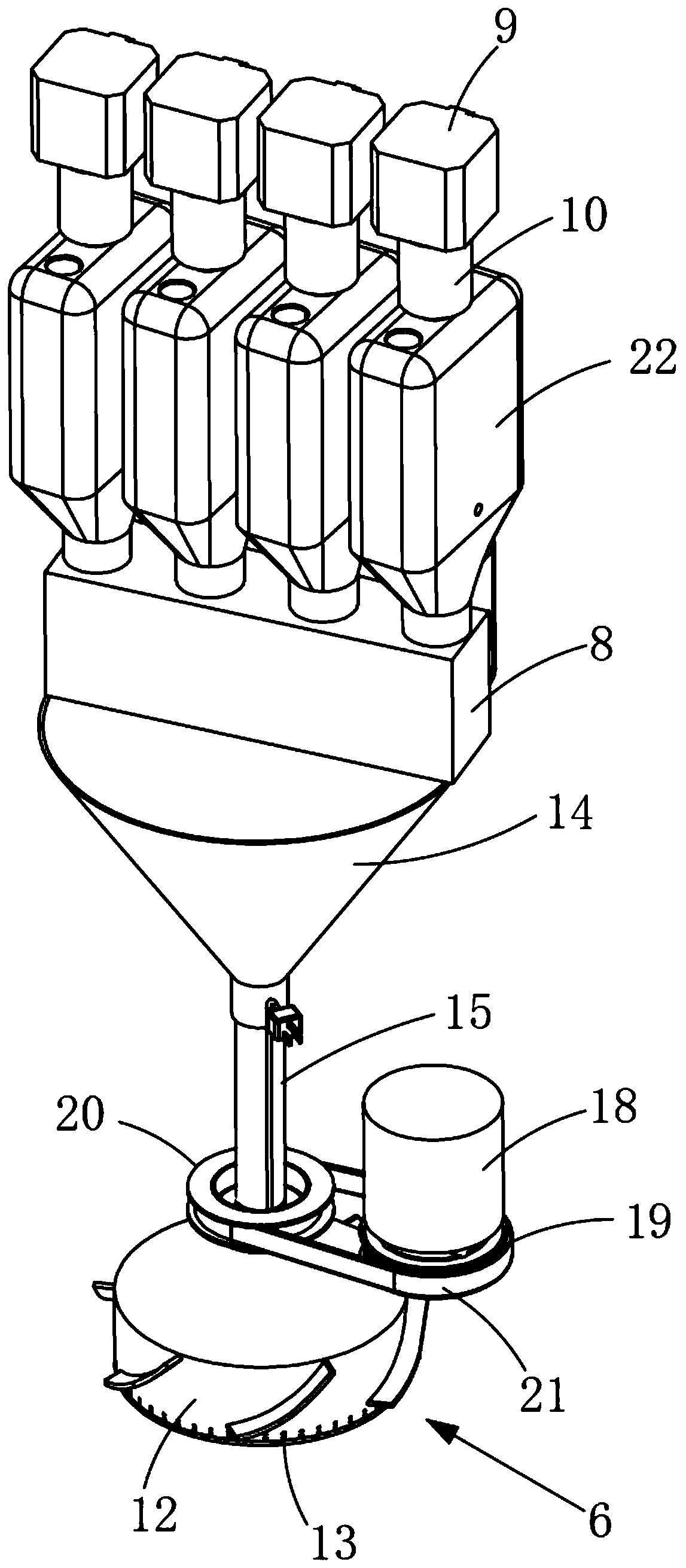

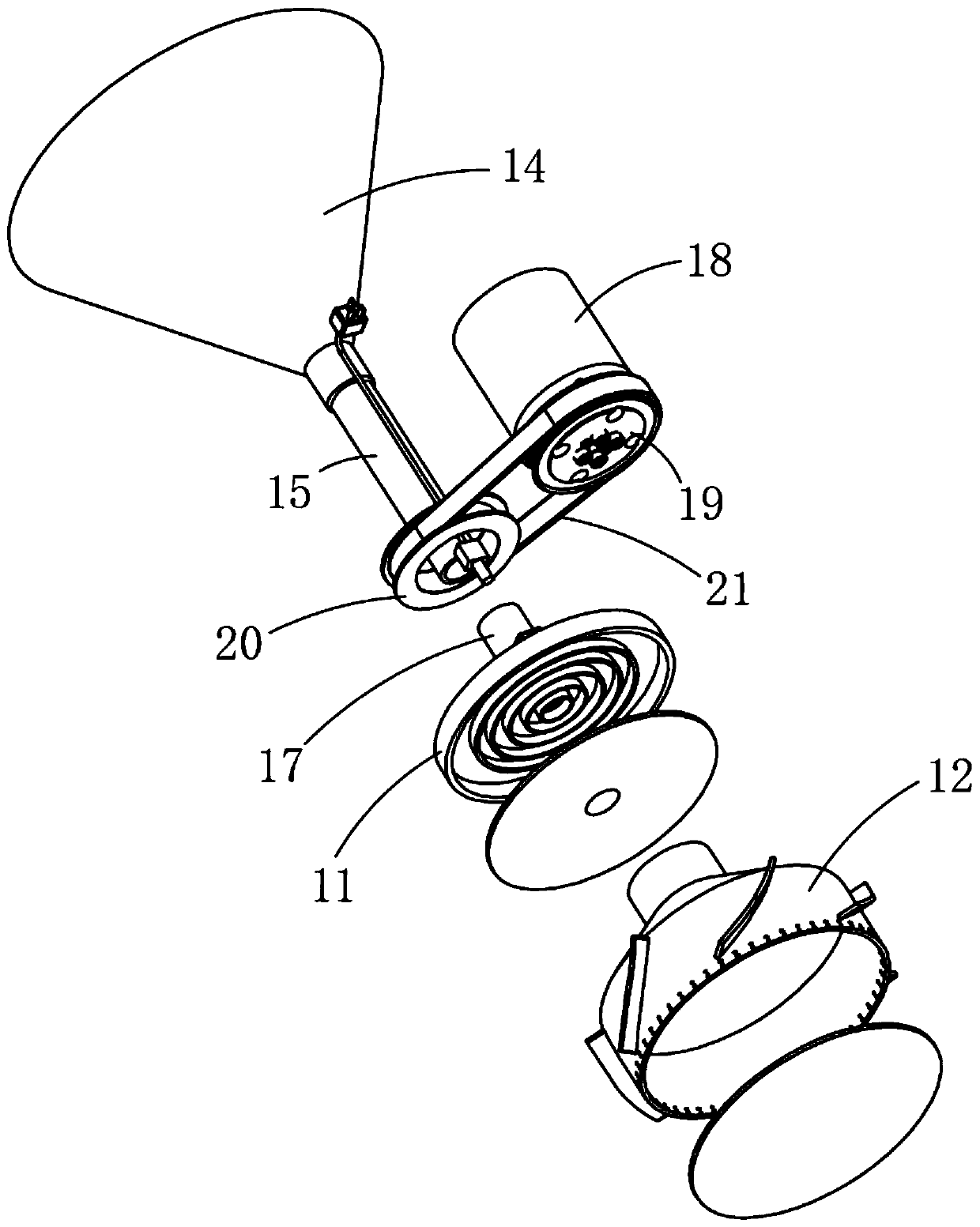

[0029] Examples, see Figure 1~3 As shown, a cotton candy machine heated in the burner includes a frame body 1, and the frame body 1 is equipped with a sugar amount control mechanism 2, a sugar box 22 module 3, a sugar discharge mechanism 4, a water tank 5, a heating mechanism 6, a rotating Mechanism 7, the sugar control mechanism 2 is installed in the sugar box 22 module 3, the sugar control mechanism 2 includes a sugar distribution box 8, a drive motor 9 and a worm 10, the sugar distribution box 8 is installed under the sugar box 22 module 3, The water tank 5 is installed on one side of the sugar dispensing box 8, the sugar dispensing mechanism 4 is installed under the sugar dispensing box 8, the heating mechanism 6 is installed on the output end of the sugar dispensing mechanism 4, and the heating mechanism 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com