Movable tobacco drying room

A flue-cured tobacco room and mobile technology, which is applied in the field of flue-cured tobacco rooms, achieves the effects of not easy to conduct heat, strong moisture retention, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

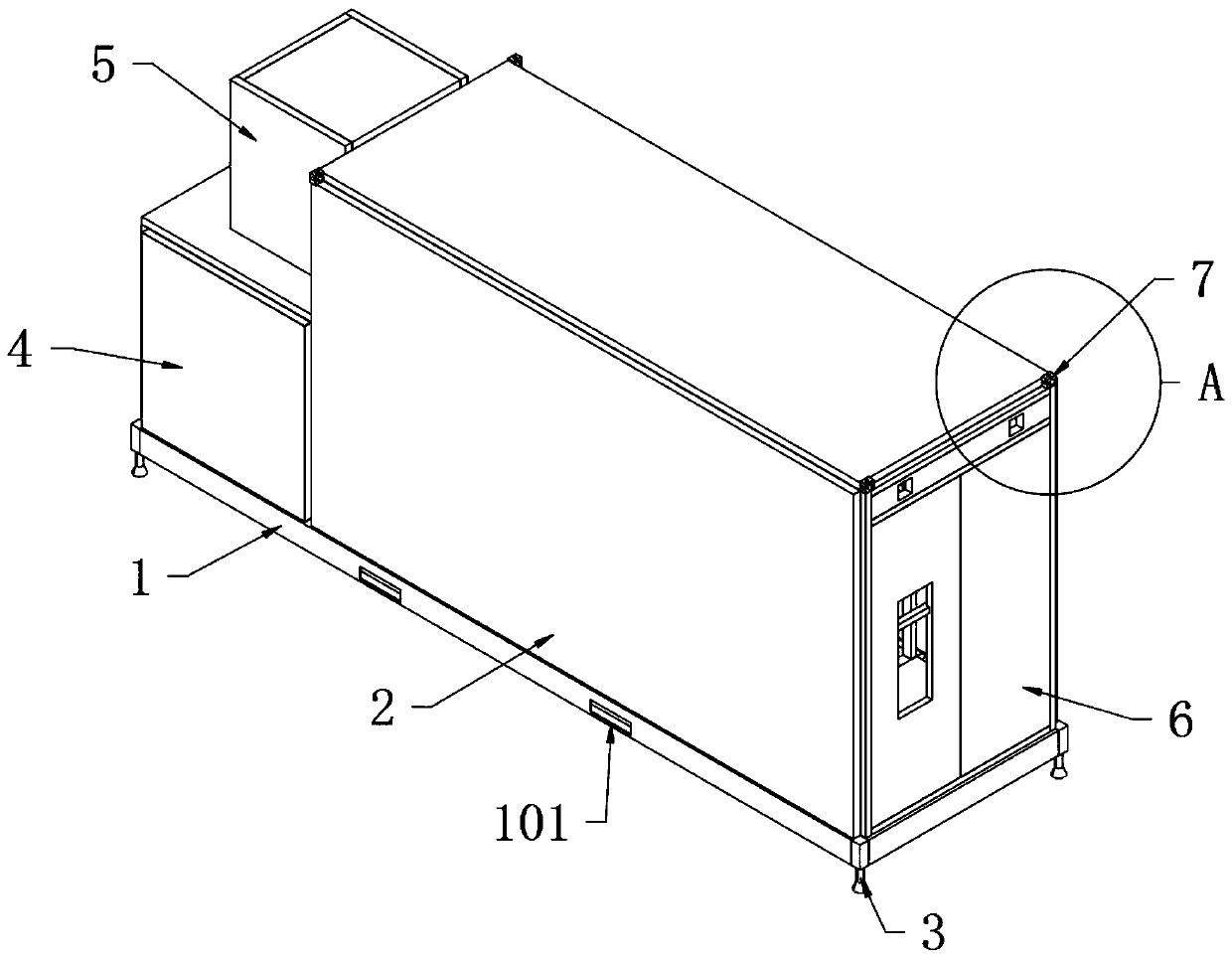

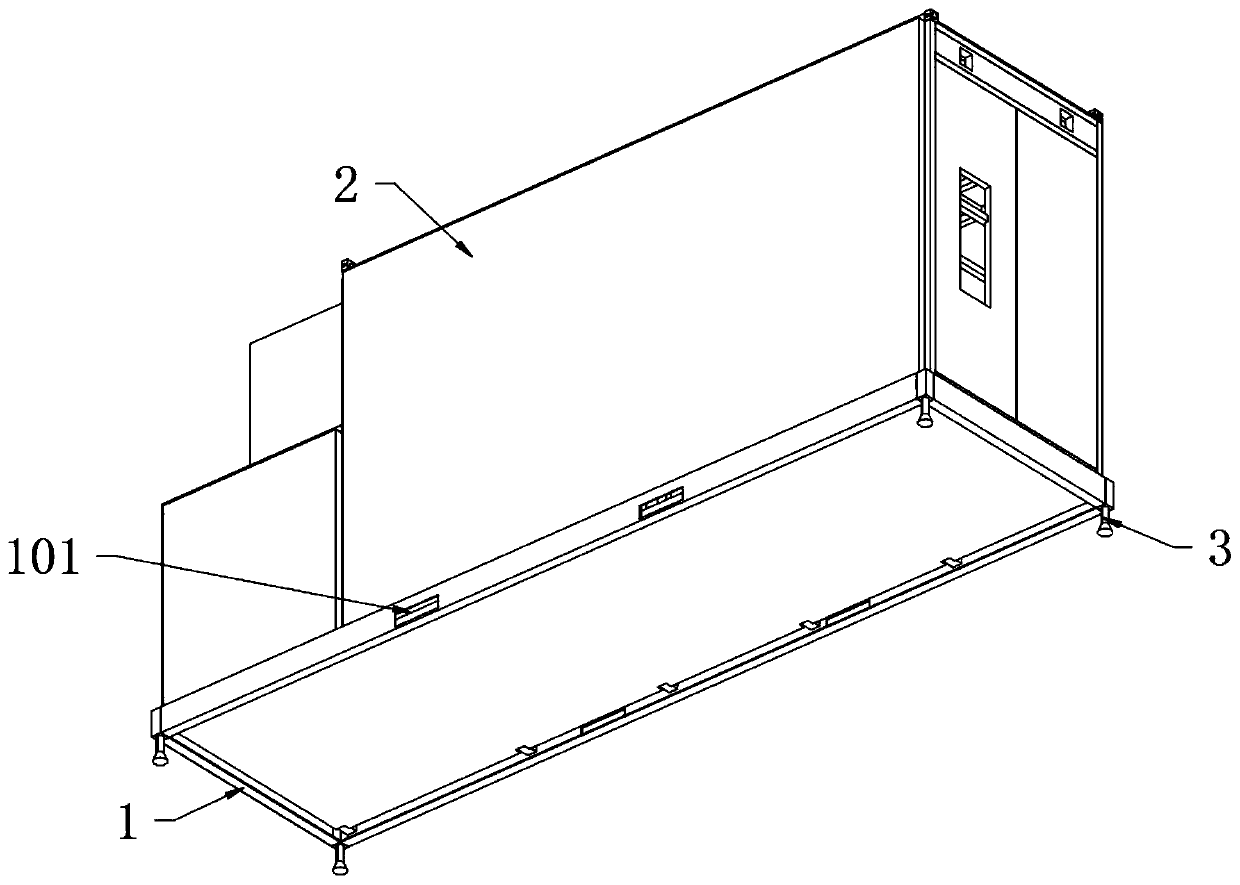

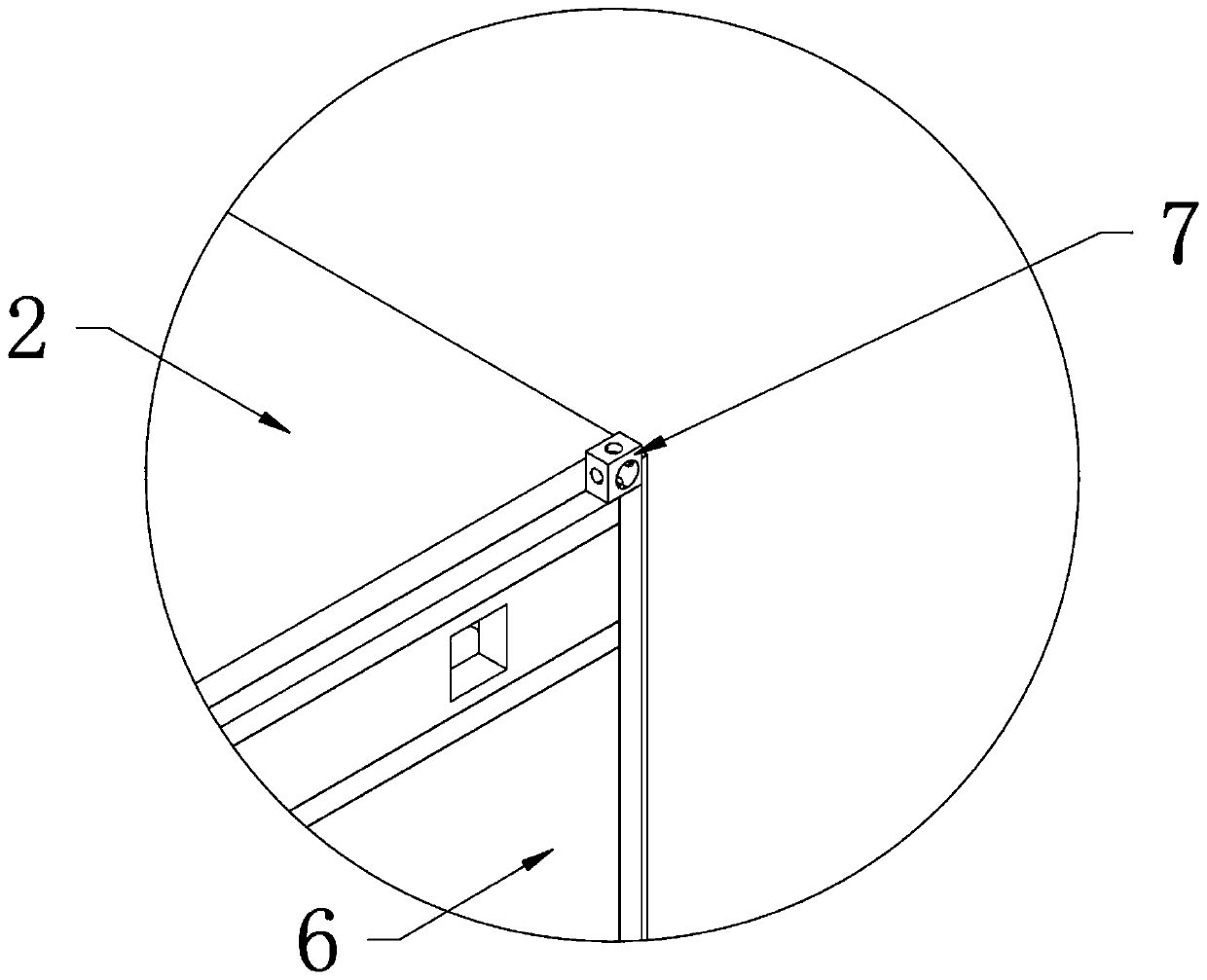

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The invention provides a movable tobacco curing room, including a channel steel base 1, a notch 101, a curing room body 2, a leveler 3, a control cabinet 4, a heating box 5, a box door 6, hanging feet 7, a combined heat pump 8 and flue-cured tobacco frame 10; the four sides of the bottom of the barn main body 2 are fixedly equipped with a channel steel base 1; the channel steel base 1 at the left end of the barn room main body 2 is fixedly installed with a control cabinet 4; Heat pump 8; a heating box 5 is fixedly installed on the top plane of the control cabinet 4, and the right end of the heating box 5 is tangent to the main body 2 of the oven; On the wall; a tobacco rack 10 is built in the main body 2 of the barn.

[0028] Wherein, two mutually symmetrical rectangular notches 101 are arranged symmetrically in the middle part of the front end crossbar and the rear end crossbar of the channel steel base 1, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap