Ternary organic fertilizer and preparation method thereof

A technology of organic fertilizers and raw materials, applied in the field of agricultural organic fertilizers and organic fertilizers, can solve the problems of disapproval of consumers, long cycle, and difficulty in playing the role of fertilizer, and achieve the improvement of living standards and quality levels, strong thermal insulation, Strong moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

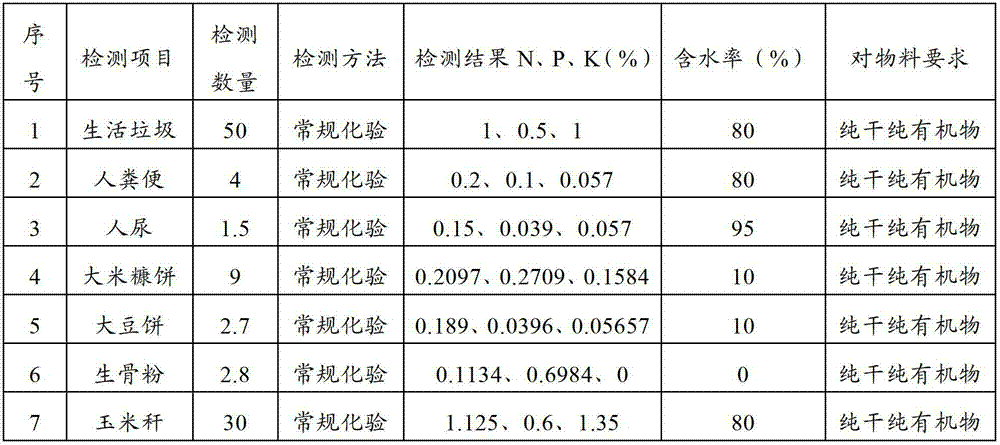

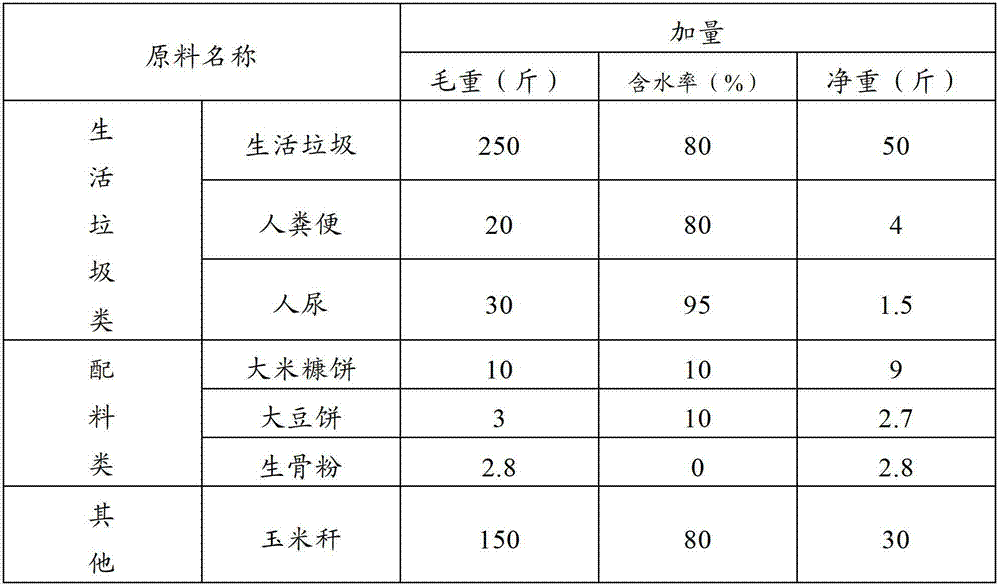

[0049] Table 2 ternary organic fertilizer formula

[0050]

[0051] 3. Production process of ternary organic fertilizer formula

[0052] The intricate technological process formed by careful processing. From material preparation to crushing, synthesis, fermentation, testing, granulation, every link has strict technical requirements.

[0053]In the process of producing organic fertilizer with household waste, GB7959-1987 sanitary standard for harmless feces must be implemented; GB8172-1987 agricultural waste control standard for urban waste; GB12801-1991 general rules for safety and health requirements in the production process; GB14554-1993 emission of odorous pollutants Standards; CJJ / T86-2000 technical evaluation indicators for urban domestic waste composting treatment plants; organic fertilizer agriculture (NY) 525 industry standards and other regulations.

[0054] (1) Technological process in the material preparation stage: 1. Determine the amount of raw materials; 2....

Embodiment 2

[0081] In 2010, four small plots of different soils were tested, the first plot was 100m 2 Wetter black soil, organic soil without chemical fertilizers, after normal plowing and harrowing, use 3 kg of ternary organic fertilizer of the present invention as base fertilizer, and plant five kinds of melon and fruit vegetables: eggplant, persimmon, capsicum, cucumber, beans, shovel Other work such as plowing and plowing is carried out as usual, and the growth after the middle period is mainly observed. The growth is good, the fruit is normal, and the taste is delicious. The second block is 100m 2 On drier loess soil, no chemical fertilizers have been applied, normal plowing, 3 kg of invented ternary organic fertilizer as base fertilizer, 400 corn plants are planted, and the growth is good; the third block is winter big boron 100m 2 Wet and dry are moderate, and the growth of celery, leeks, lettuce, and spinach is roughly the same as before. The fourth block is 100m 2 White pulp ...

Embodiment 3

[0083] In 2011, with two pieces of the same 100m 2 In the soil test, the first piece is a paddy field, which is the same as before, without any special treatment. The rice is planted with 5kg of fertilizer, and the growth is balanced; the second piece is a mountain with a steep slope, which belongs to loess. Soybeans are planted with 4kg of fertilizer, and the moisture retention is observed. , heat preservation, ventilation, light transmission, absorption, and dissolution, the observed growth is no different from before.

[0084] 4. Test results of ternary organic fertilizer formula

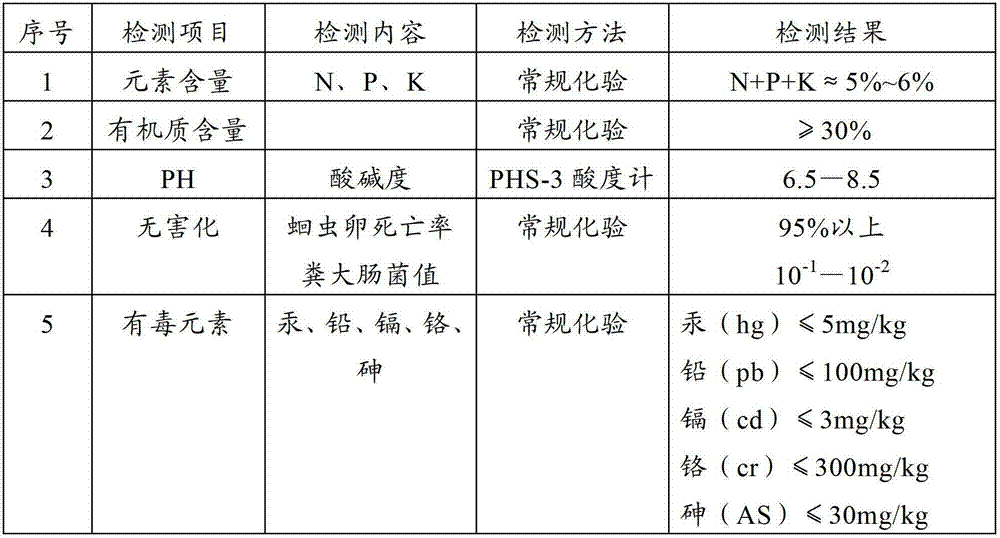

[0085] Table 3 Test table of five major indicators of organic fertilizer

[0086]

[0087] Conclusion: 1. The fertilizer made with this formula, not only the three elements exceed the N+P specified in NY525-2002 2 o 5 +K 2 O=4% standard, also contains a certain amount of medium elements (calcium, magnesium, sulfur) and many trace elements. 2. This formula has a lot of organic matter, more...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap