Removable denture and manufacturing technology thereof

A removable denture and preparation process technology, applied in the field of oral prosthodontics, can solve problems such as the inability to use removable dentures normally, and achieve the effects of convenient and fast wearing, good antibacterial ability, and saving manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

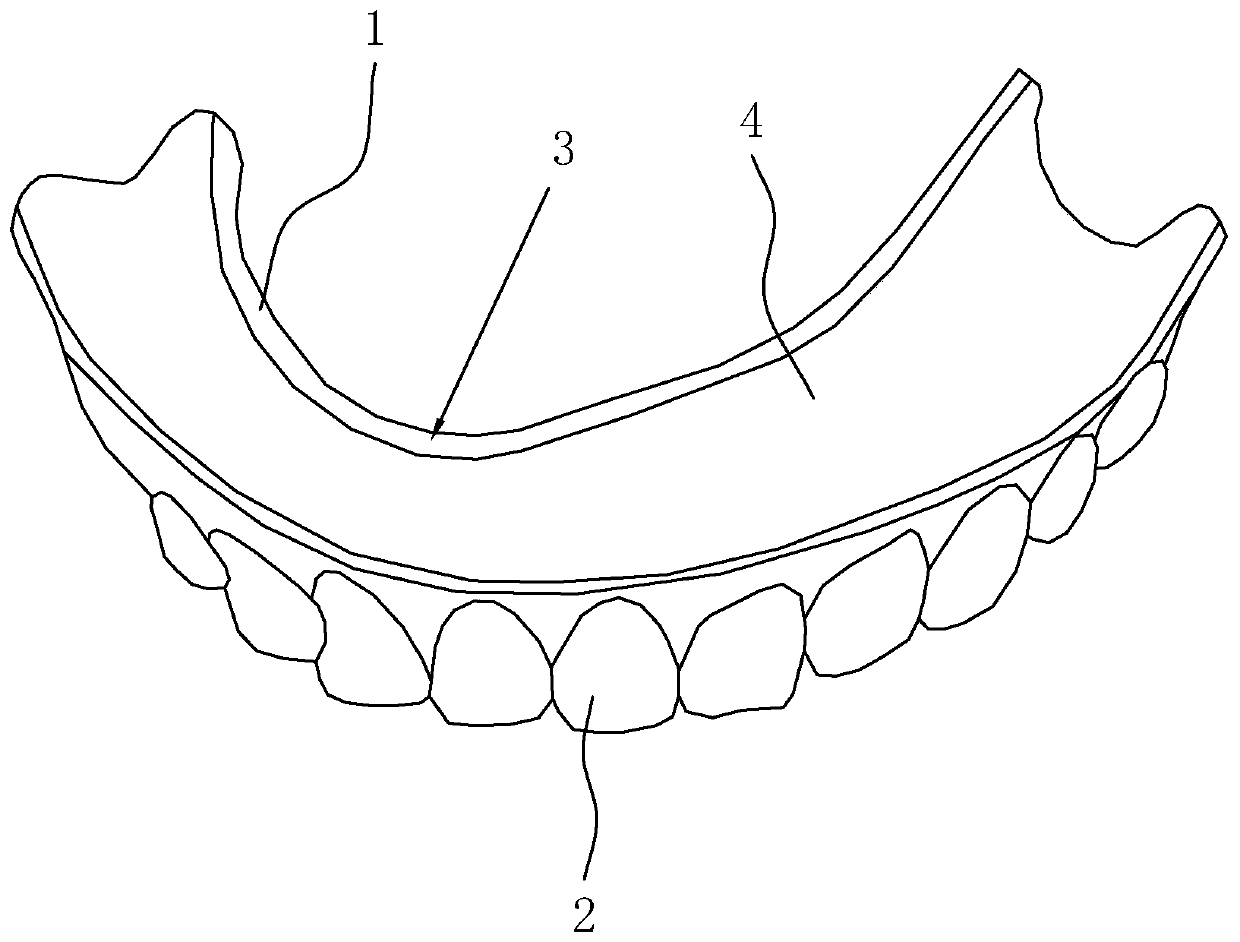

[0046] Embodiment one: refer to figure 1 , is a removable denture disclosed by the present invention, which includes a base 1 made corresponding to the alveolar ridge of the human body and a bionic tooth 2 connected to one side of the base 1. During the production process, the base 1 corresponds to the alveolar ridge of the human body in the bionic A fitting groove 3 is formed on the opposite side of the tooth 2, and the fitting groove 3 can fit the alveolar ridge of the human body after the movable denture is worn into the mouth.

[0047] Since the base 1 is made of resin material, it still has greater hardness compared with the alveolar ridge of the human body, so some patients will have obvious pain when chewing after wearing it. Therefore, the fitting groove 3 of the base 1 is provided with a There is an elastic cushioning layer 4 for cushioning. The elastic buffer layer 4 is made of silicon rubber material, and nano-silver powder with antibacterial and antibacterial prop...

Embodiment 2

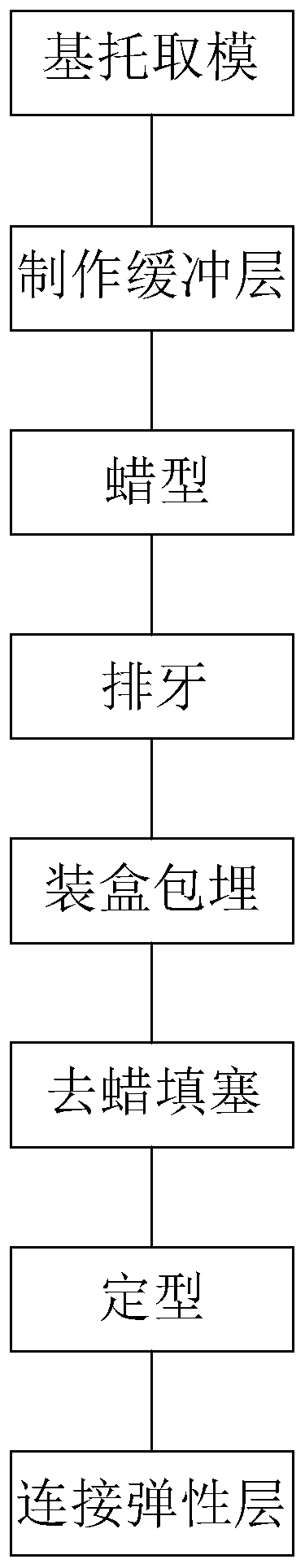

[0051] Embodiment two: refer to image 3 and Figure 4 , is the preparation method of a kind of removable denture disclosed by the present invention, comprises the following steps:

[0052] a: Take an impression of base 1, use medical tools to take out the impression in the patient's mouth, and make two identical gypsum base 1 models A and B that are similar to the patient's mouth according to the impression;

[0053] b: Make a buffer layer, and make an elastic buffer layer 4 with the help of the gypsum base 1 model B;

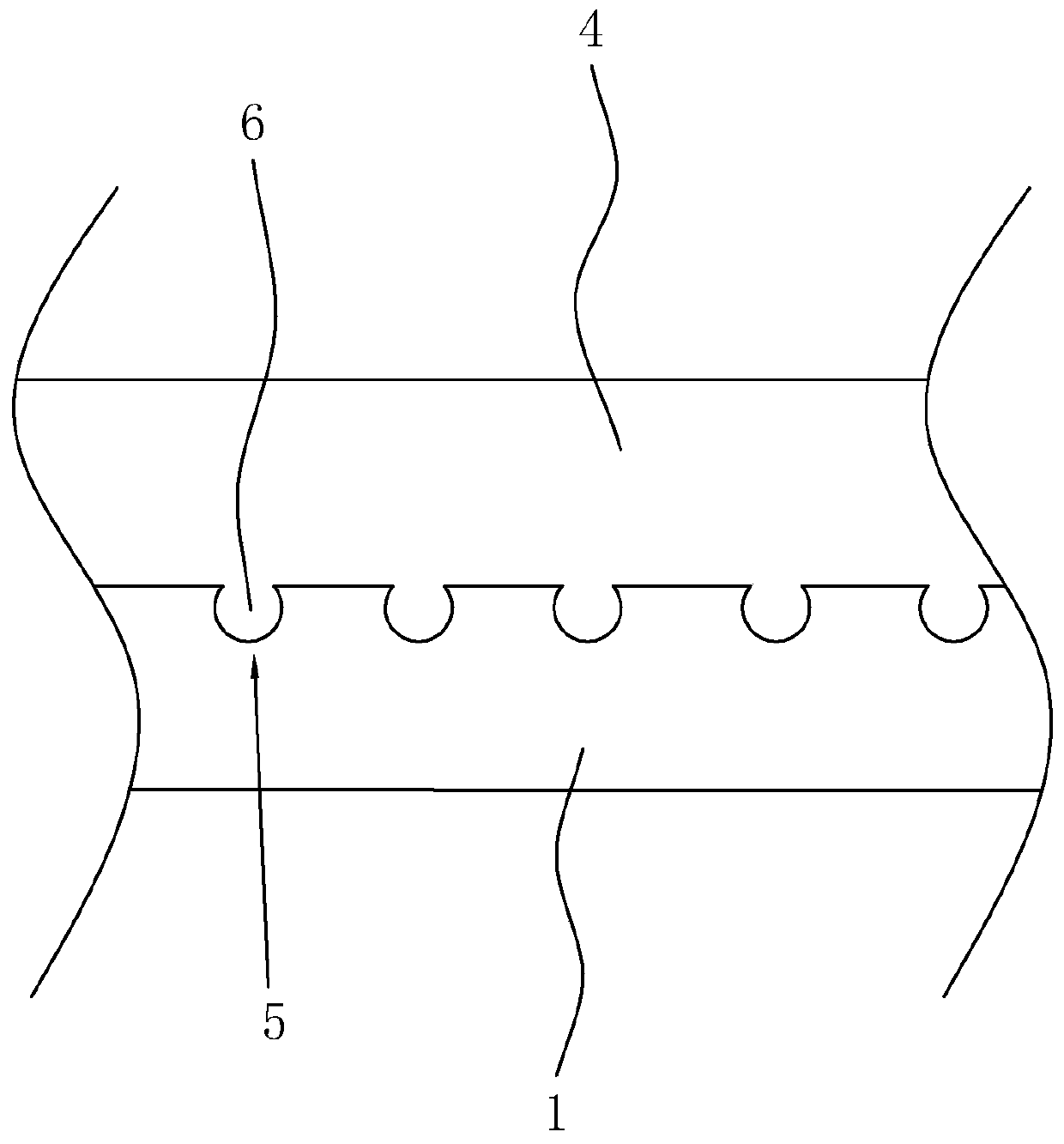

[0054] b1: Open the connection hole groove 5, and set the connection hole groove 5 with the same position and size at the bottom of the fitting groove 3 formed on the obtained gypsum base 1 models A and B;

[0055] b2: wax-up, wax-up of the obtained gypsum base 1 model B;

[0056] b3: box embedding, put the plaster base 1 model B after wax-up into the embedding box and pour it with gypsum;

[0057] b4: Wax removal and filling. Put the embedding box of b3 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com