Mixing device and mixing process for food processing

A mixing device and food processing technology, applied in mixers, mixing methods, and post-processing of mixtures, etc., can solve the problems of inconvenient cleaning, inability to continuously supply materials, and cover a wide area, and achieve a simple and compact structure and save electricity. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

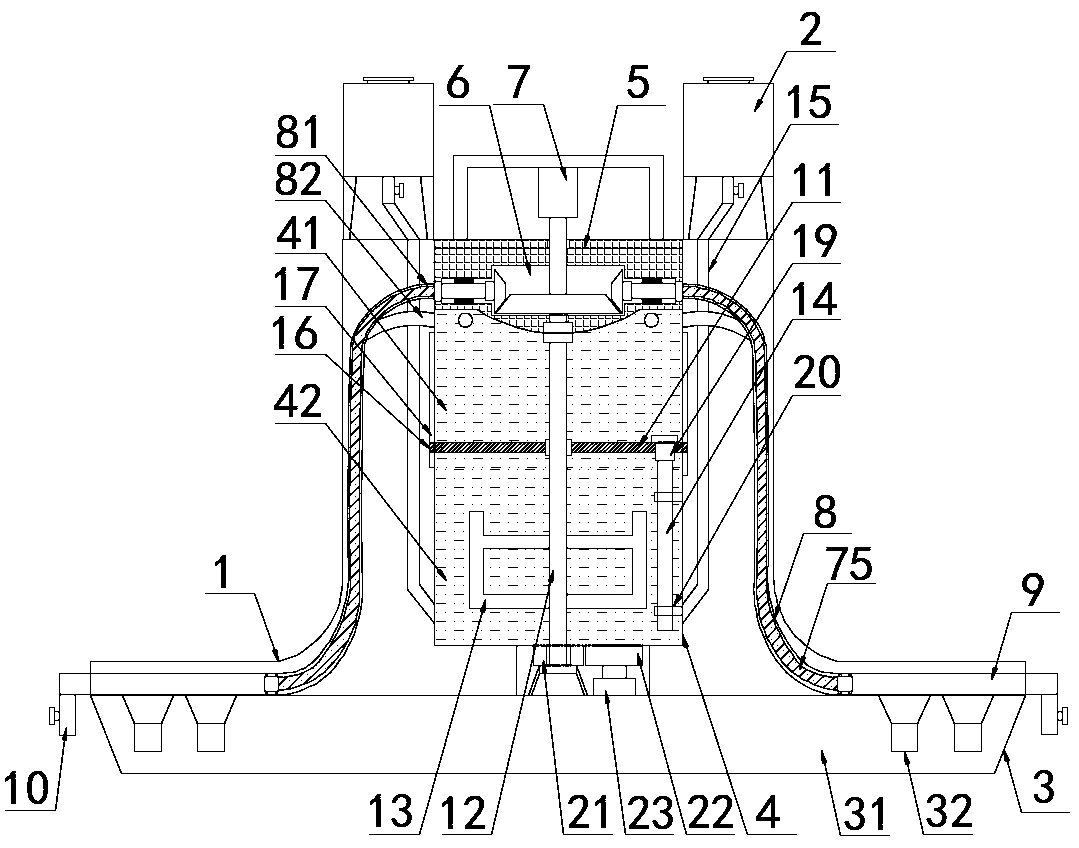

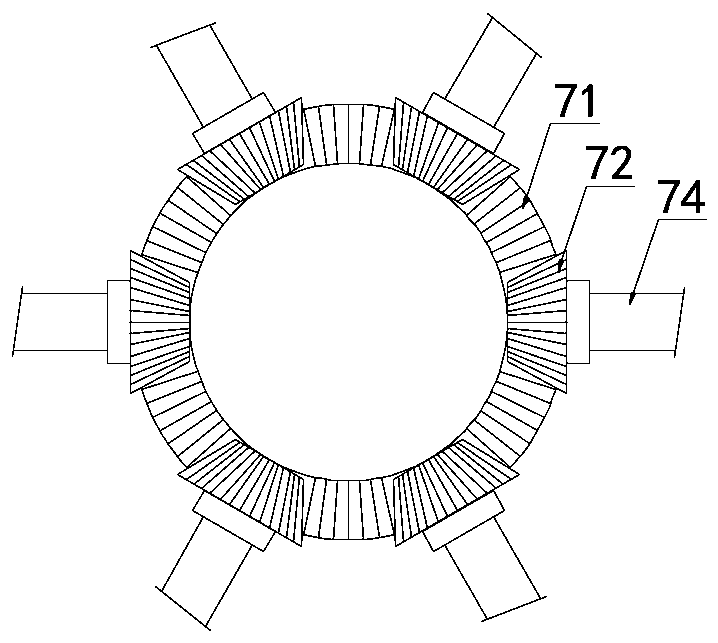

[0036] The present invention provides such Figure 1-3 A mixing device for food processing is shown, which includes a body 1, the top of the body 1 is surrounded by a lowering box 2 and the bottom is provided with a defoaming table 3, and the inside of the body 1 is provided with two uninterrupted feed bins 4 And the upper top cover 5, the upper top cover 5 is arranged on the top of the uninterrupted two-point feed bin 4, the inside of the upper top cover 5 is provided with a mixing control bin 6, and the inside of the mixing control bin 6 is provided with a mixing The driving mechanism 7, the outer side of the mixing control chamber 6 is provided with a plurality of surrounding discharge channels 8, the ends of the discharge channels 8 are connected to the horizontal discharge channel 9, and the bottom of one end of the horizontal discharge channel 9 is connected to a The discharge pipe 10, the uninterrupted two-point silo 4 includes an upper hopper 41 and a mixing silo 42 th...

Embodiment 2

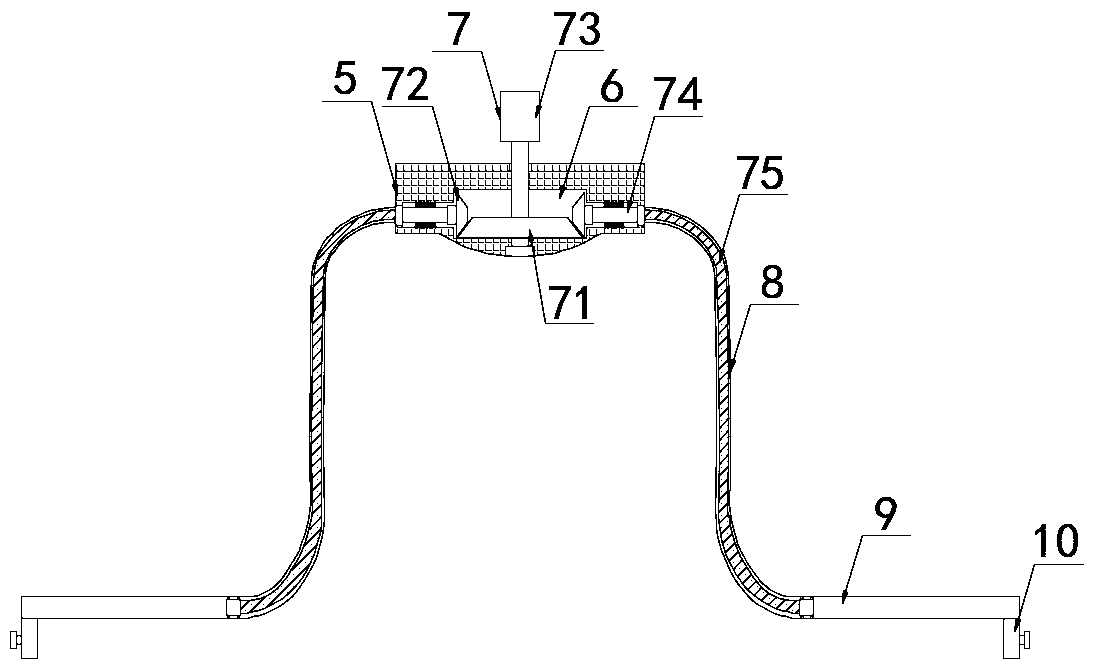

[0054] The present invention provides such figure 2 As shown in a mixing device for food processing, the soft steel bar 75 extends to the inside of the top inlet 81, and the two ends of the discharge channel 8 are arranged in a curved shape with opposite bending directions, so as to avoid bending and hindering the rotation of the soft steel bar 75 , wear soft steel bar 75, first bearing is provided outside described soft steel bar 75 two ends, and described first bearing is fixedly connected with discharge channel 8 by bracket;

[0055] The present invention provides such Figure 4 As shown in a mixing device for food processing, a slider is provided between the partition sealing plate 11 and the screw rod 12, and the inner wall of the slider is provided with an internal thread that matches the thread of the outer wall of the screw rod 12. The partition Both sides of the sealing plate 11 are fixed with sliding feet 16, and the inner wall of the upper material bin 41 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com