Flexible lifting system

A lifting system and flexible technology, which is applied in the direction of lifting frames, lifting devices, and object stacking, can solve the problems of high installation site requirements for Z-direction telescopic manipulators, and achieve the effects of light weight, universal adaptability, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

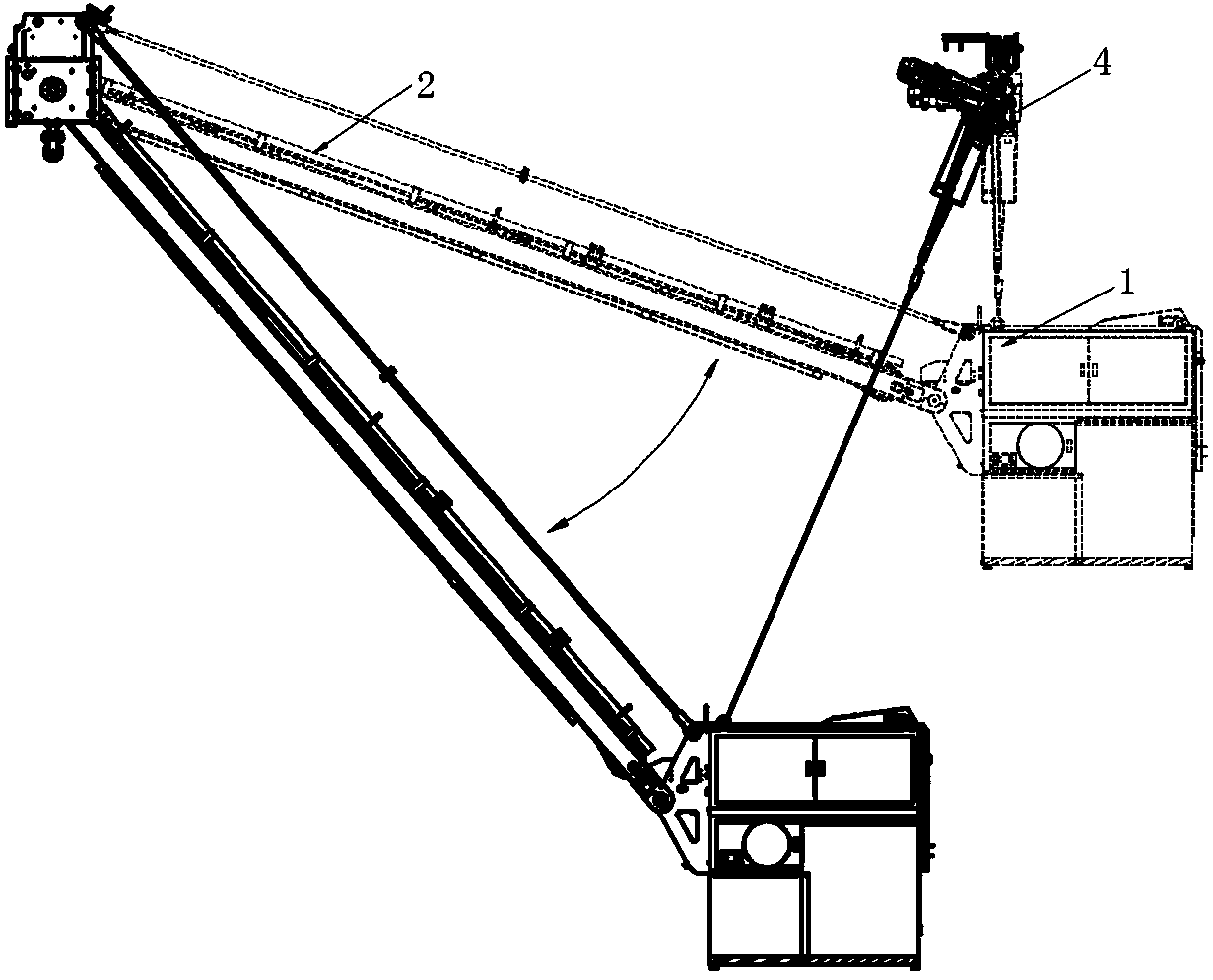

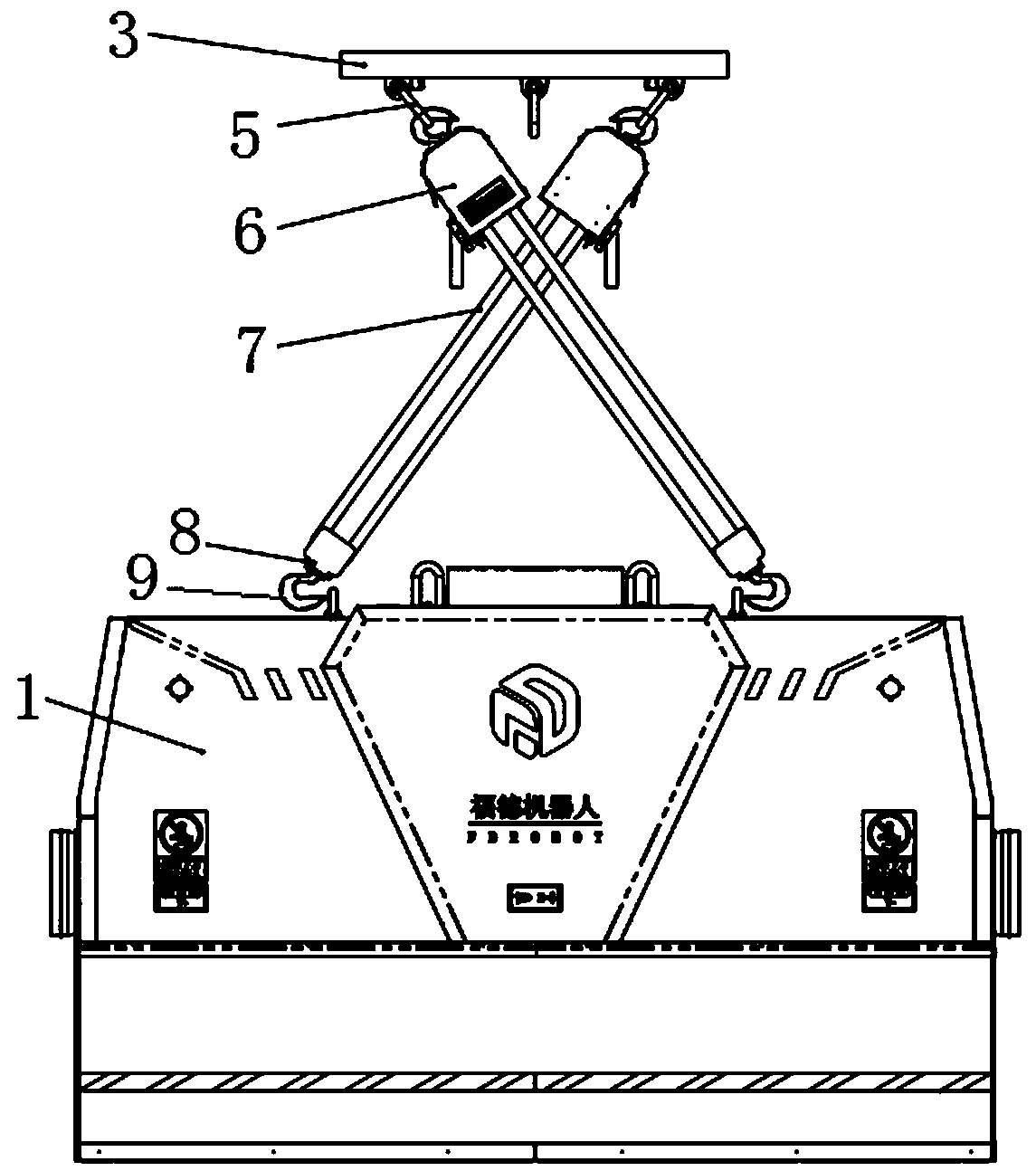

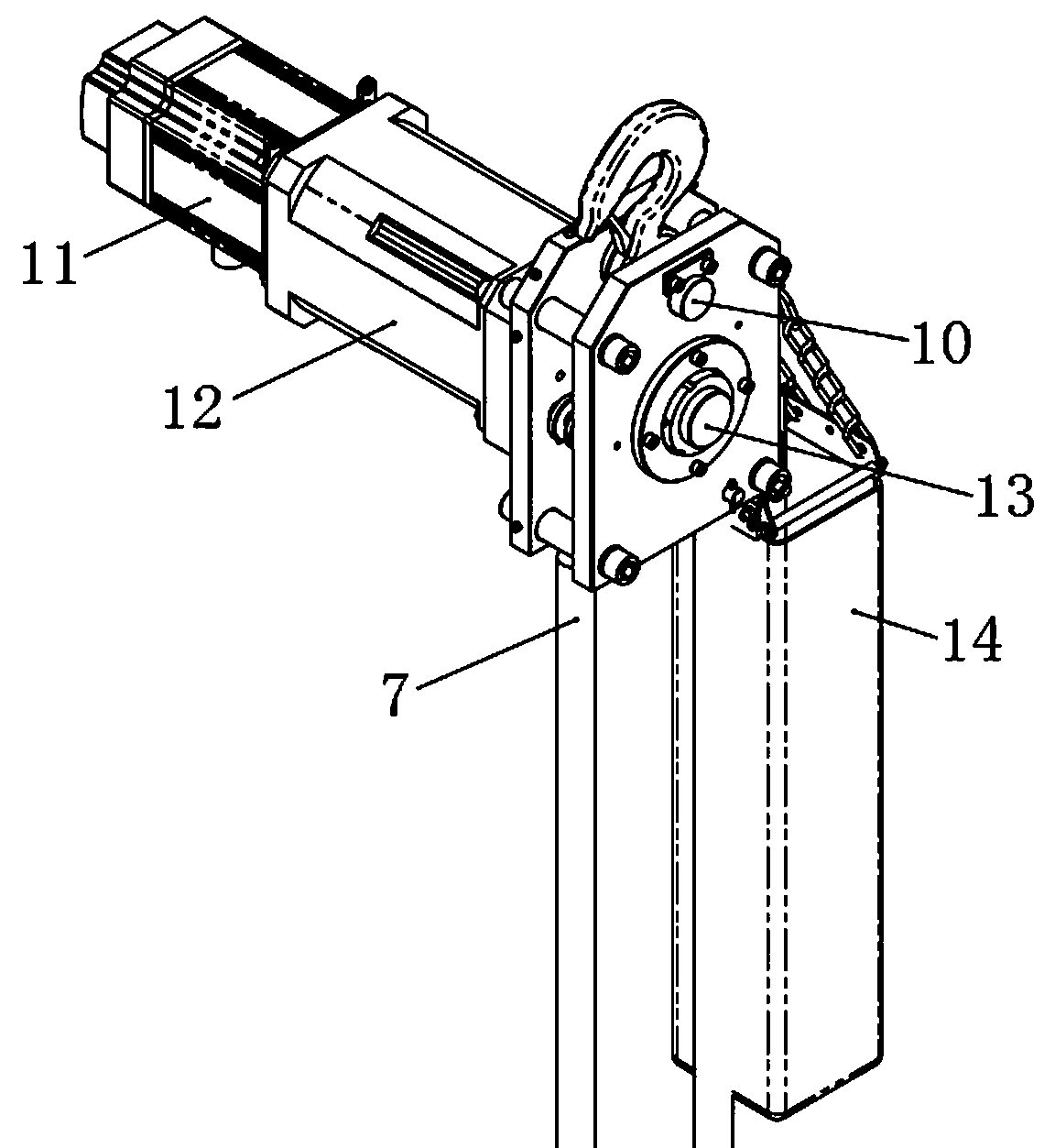

[0057] The flexible lifting system of this embodiment includes a transmission unit, a support base, a drive unit, and a control system. In this embodiment, the upper end of the driving unit is connected to the support base, and the lower end of the driving unit is connected to the stacker head; as shown in the figure, two driving units are used, and the driving units are arranged crosswise.

[0058] Wherein, the conveying unit includes a conveying line, a material input end, a material output end, an upper input rod, and a lower input rod, and the material input end and the material output end are respectively arranged at two ends of the conveying line. In this structure, the bag-like material is input through the material input end, and the bag-like material entering from the material input end sequentially passes through the conveying line and the material output end into the palletizer head for the stacking operation. In this embodiment, the two ends of the lower input rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com