Method for preventing and controlling rock burst through energy release modification of deep well high-stress main roadway coal pillar

A technology of rock burst and high stress, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as reducing the elastic energy accumulated in coal pillars with high stress, high requirements for anchor cable materials, and complicated coal pillar construction. , to reduce elastic energy, weaken energy storage capacity, and solve the effect of reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

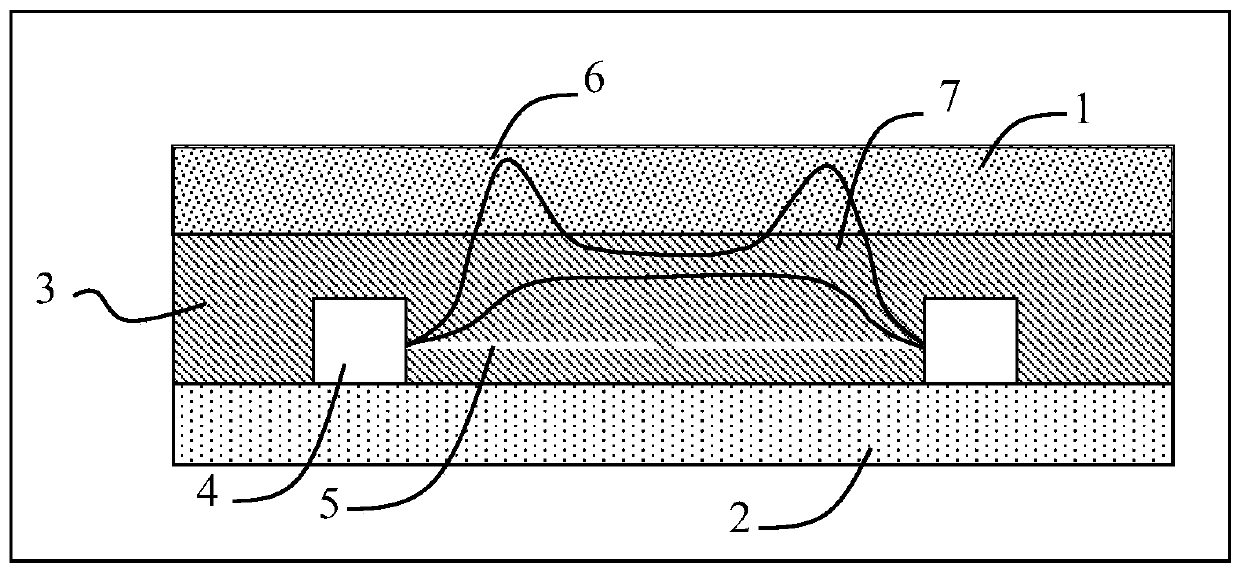

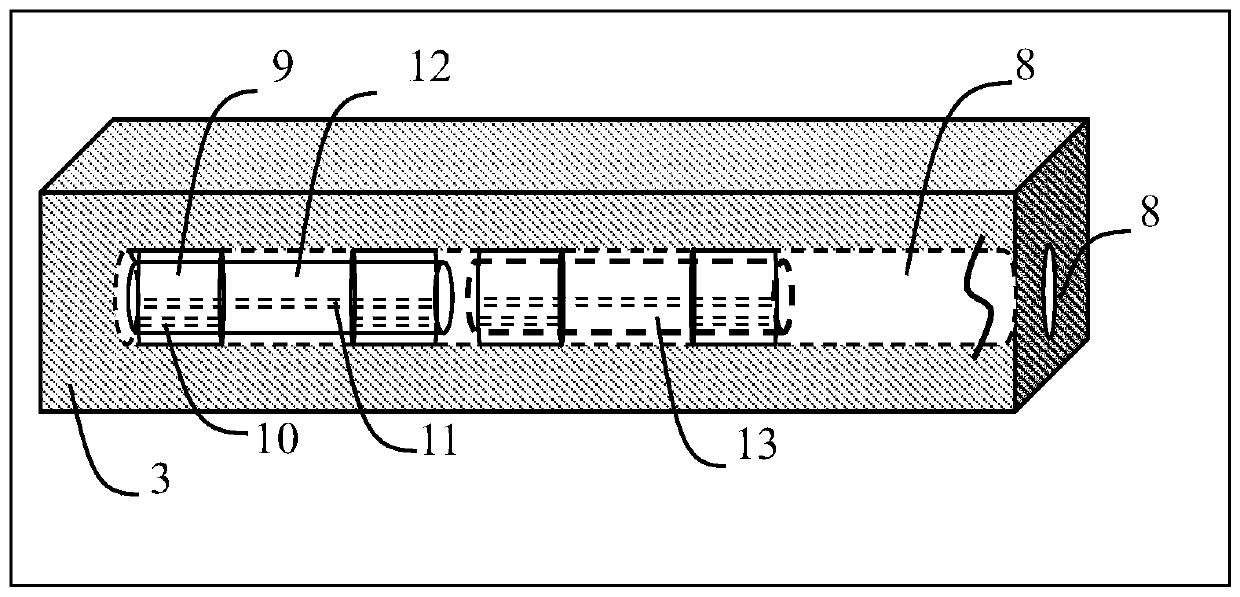

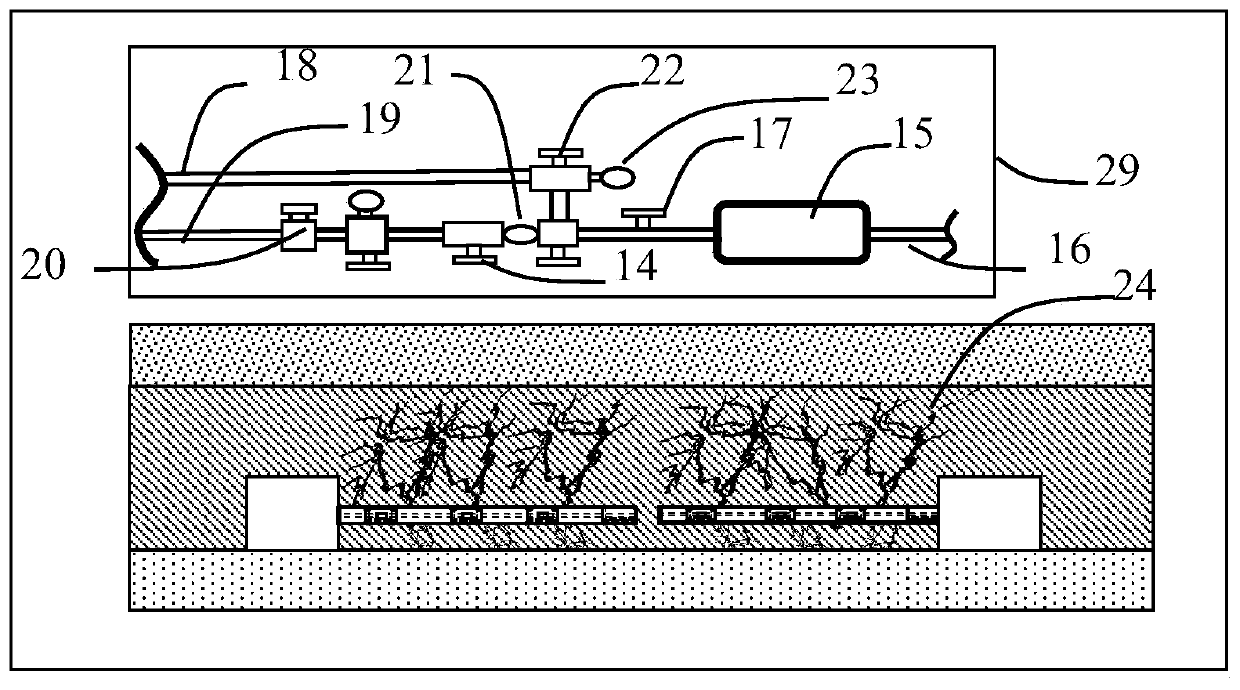

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides a method for preventing and controlling rock burst through energy release modification of coal pillars in deep wells and high stress roadways.

[0026] The method includes steps as follows:

[0027] S1: Implement large-diameter pressure relief drilling to release the elastic energy of coal accumulation;

[0028] S2: Perform ultra-high pressure fixed-point hydraulic fracturing in large-diameter boreholes to crack the complete coal pillar and weaken the energy storage capacity of the roadway coal pillar;

[0029] S3: Implement grouting reinforcement to the coal pillars of the main road after fracturing, increase the strength of the coal pillars of the main road, and increase the impact threshold;

[0030] S4: Implement reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com