LNG large water bath type gasification system and method utilizing same

A gasification system, water bath technology, applied in the direction of container filling method, container discharge method, heat exchanger type, etc., can solve the problems of inability to realize LNG gasification heating of large LNG storage tanks, limit the temperature range of heating, etc. Achieve the effect of avoiding high equipment investment, large heat transfer coefficient, and efficient LNG gasification heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

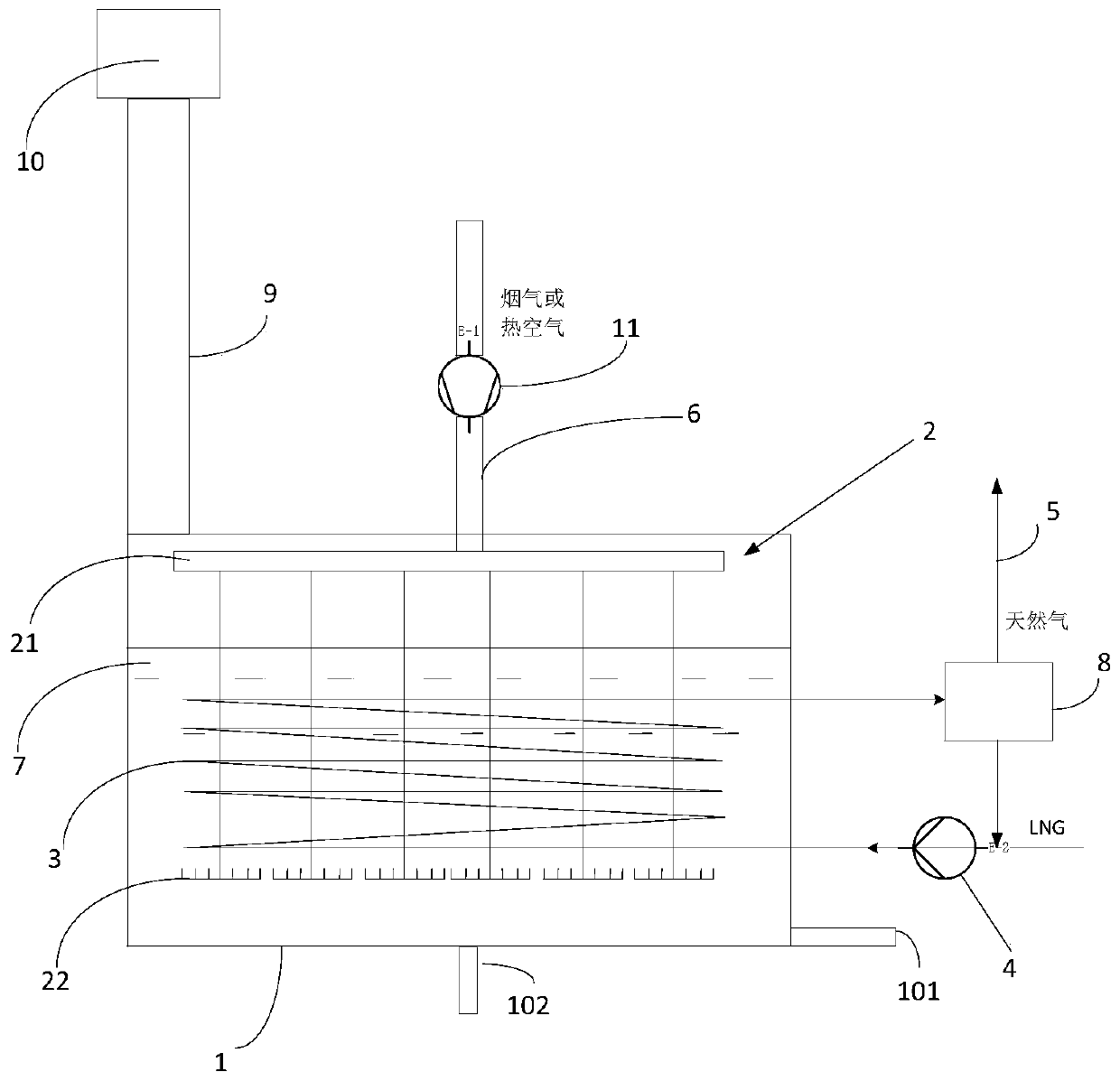

[0042] This embodiment provides an LNG large-scale water bath gasification system, such as figure 1 As shown, it includes a liquid heating water bath 1, a heat source gas injection and distribution device 2, a LNG vaporization heating heat exchange tube bundle 3, a booster pump 4, a natural gas pipeline 5, and a heat source gas connecting pipeline 6; the liquid heating water bath 1 The heat exchange liquid medium 7 is contained inside; the gas inlet of the heat source gas injection and distribution device 2 is connected to the heat source gas connecting pipeline 6, and the gas outlet is located in the liquid heating water bath 1; the LNG gas The chemical heating and heat exchange tube bundle 3 is arranged in the liquid heating water bath 1, one end of which is connected to the booster pump 4, and the other end is connected to the natural gas pipeline 5; the booster pump 4 is connected to an LNG storage device.

[0043] In this embodiment, the system further includes a gas-liquid...

Embodiment 2

[0063] This embodiment provides a design method of the system as described in Embodiment 1, including the following steps:

[0064] S1. According to the capacity of the LNG storage device, the flow rate of the booster pump, and the required gas supply temperature of the final natural gas, the heat exchange required for gasification of the set flow rate of LNG is calculated according to the following formula:

[0065] Q LNG total = F LNG *Q gasification +F LNG *(T for -T LNG )*C p gas

[0066] Q LNG total The total energy required to vaporize LNG and reach the supply temperature, kJ / h; Q gasification Energy required for LNG gasification, kJ / h; F LNG Is the LNG flow rate, kg / h; C p gas Is the specific heat capacity of natural gas, kJ / kg℃; T for Is the temperature of external natural gas supply, ℃; T LNG Is the temperature after LNG gasification, ℃;

[0067] S2 According to the type of heat exchange tube selected, query the heat exchanger design manual to obtain the air convect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com