Method of making a laminated wood product

A wood product, longitudinal direction technology, applied in the direction of wood layered products, wooden veneer joints, layered products, etc., can solve the problems of large material loss, achieve no reduction in strength performance, increase total output, and improve humidity Effects of Change Tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

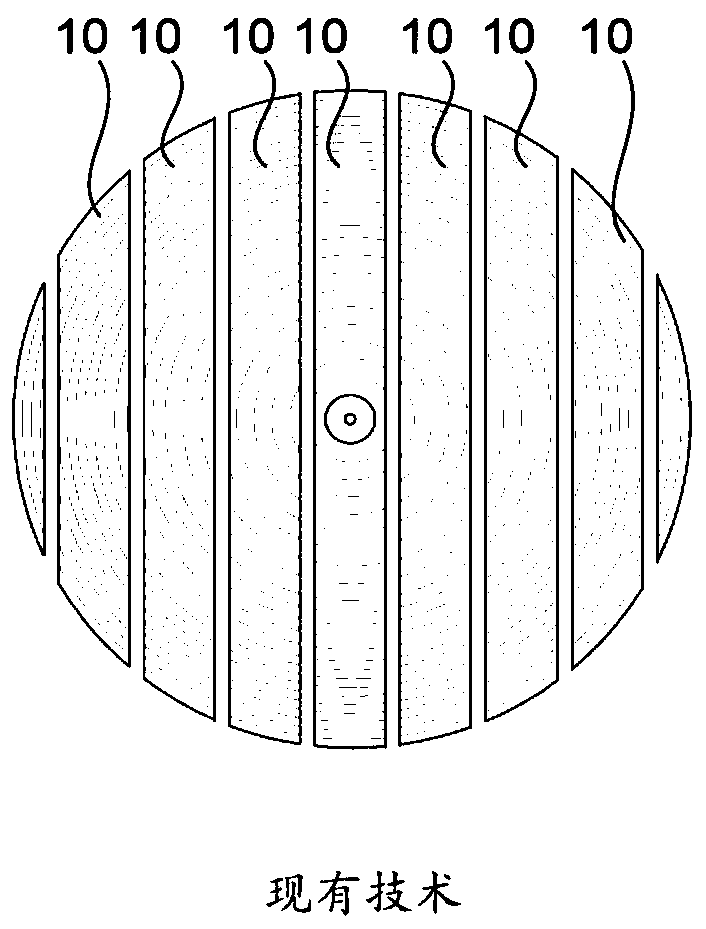

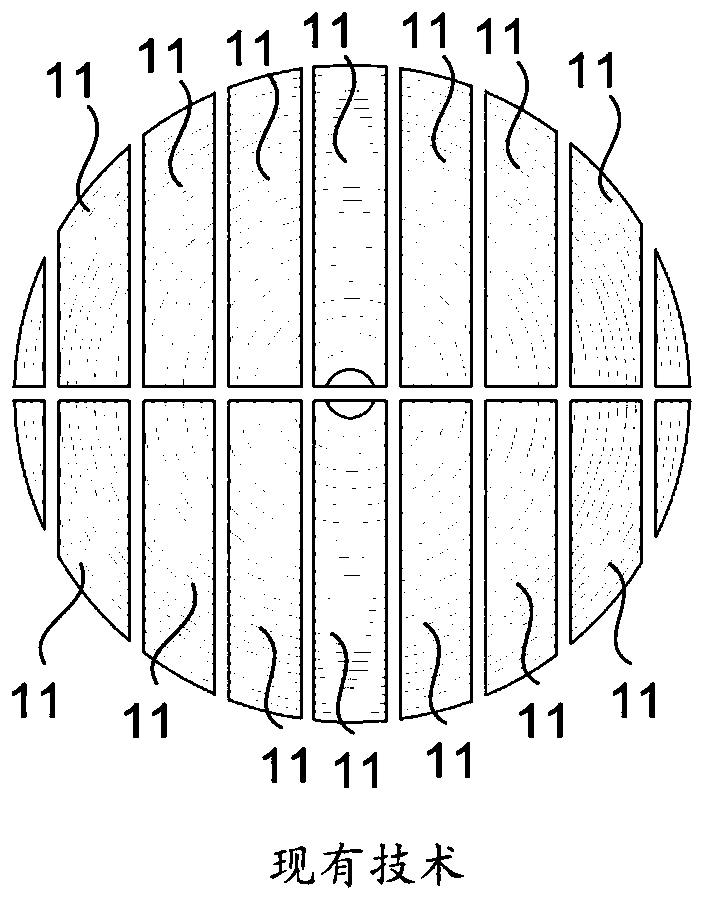

[0089] Figures 4a-4d and 5a-5b show a strategy to increase overall yield: if you keep the plate integrity ( Figure 4b ), there will be no two identical boards, so it will be difficult to fit them in one layer with small gaps. Usually you'll trim the edges to get a board with parallel edges. On the other hand, most boards can be split symmetrically in the middle so that the two halves fit together nicely, as shown, which results in layers where there is a fairly small gap between the board and the small trim scrap.

[0090] Figures 4a-4d It schematically shows how the generally trapezoidal slats 20 are cut longitudinally and rearranged so as to provide an approximately rectangular polymeric panel. For example, the stave 20 may be cut along a longitudinal line to form a pair of stave blocks 21a, 21b. By moving the position of the slat pieces 21a, 21b so that their rounded edges face each other and also rotating one of the slat pieces 21b about an axis parallel to the widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com