Making method of sauce fragrance type hotpot condiment

A technology of hot pot bottom material and production method, which is applied in the field of food processing, can solve the problems of cooking fumes, exhaust gas and oily wastewater, etc., and achieve the effects of solving frying temperature control, improving redness, and pure and natural fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

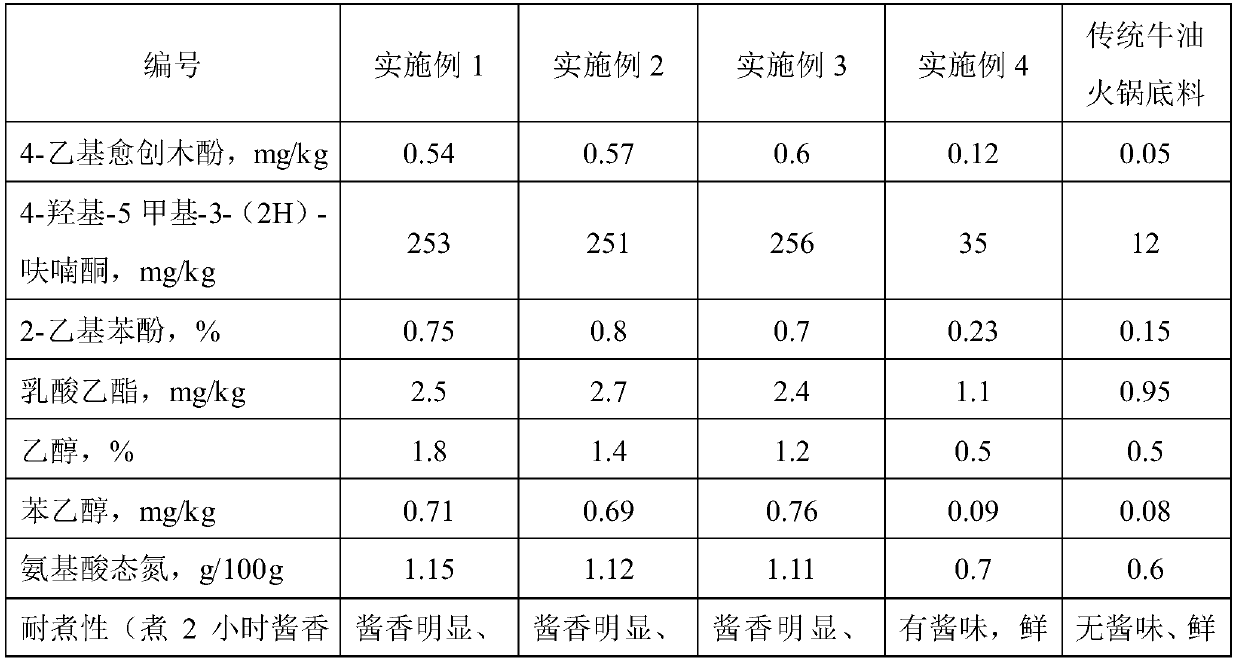

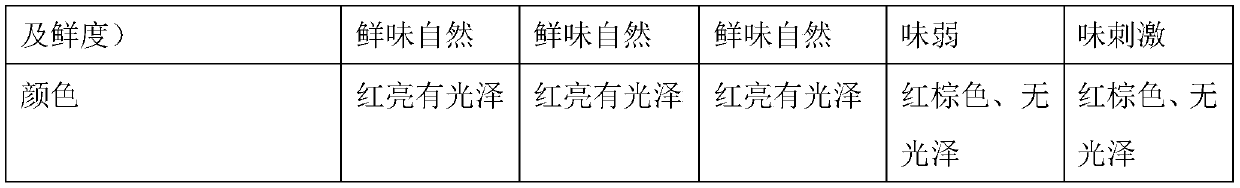

Examples

Embodiment 1

[0034] A kind of preparation method of sauce-flavored chafing dish bottom material of the present invention comprises the following steps:

[0035] 1. Preparation of high-salt dilute fermentation mature sauce mash:

[0036] (A) Preparation of fried soybeans: Dried soybeans were fried at 140°C for 20 seconds, and then fried soybeans were obtained after cooling;

[0037] (B) preparation of dried capsicum: dried capsicum is cut into the section of 0.5cm with the cutter for subsequent use;

[0038] (C) Soy sauce fermentation: soak soybeans in hot water at 40°C for 30 minutes, drain the water, cook in a cooking pot with a pressure of 0.15Mpa, a temperature of 115°C, and a time of 10 minutes. After cooking, cool to 45°C and add fried Wheat flour and fried wheat flour are fried in advance by a wheat frying machine at 140°C for 30 seconds, and then crushed through a 40-mesh sieve to obtain fried wheat flour; add 0.1% of Aspergillus oryzae seed koji, and send it to the koji making mac...

Embodiment 2

[0053] A method for preparing sauce-flavored hot pot bottom material, comprising the following steps:

[0054] 1. Preparation of high-salt dilute fermentation mature sauce mash:

[0055] (A) Preparation of fried soybeans: Dried soybeans were fried at 135°C for 25 seconds, and then fried soybeans were obtained after cooling;

[0056] (B) Preparation of dried chili (millet pepper): dried chili is cut into 0.7cm sections with a twist cutter for subsequent use;

[0057] (C) Soy sauce fermentation: soak soybeans in hot water at 43°C for 25 minutes, drain the water, cook in a cooking pot with a pressure of 0.12Mpa, a temperature of 112°C, and a time of 12 minutes. After cooking, cool to 43°C and add fried Wheat flour and fried wheat flour are fried by a wheat frying machine at 145°C for 25s in advance, and then crushed through a 40-mesh sieve to obtain fried wheat flour; add 0.2% of Aspergillus oryzae seed koji, and send it to the koji making machine at a temperature of 33°C and a ...

Embodiment 3

[0072] A method for preparing sauce-flavored hot pot bottom material, comprising the following steps:

[0073] 1. Preparation of high-salt dilute fermentation mature sauce mash:

[0074] (A) Preparation of fried soybeans: Dried soybeans were fried at 140°C for 20 seconds, and then fried soybeans were obtained after cooling;

[0075] (B) Preparation of dried chili (millet pepper): dried chili is cut into 1cm sections with a twist cutter for subsequent use;

[0076] (C) Soy sauce fermentation: soak soybeans in hot water at 45°C for 20 minutes, drain the water, cook in a cooking pot with a pressure of 0.10Mpa, a temperature of 110°C, and a time of 15 minutes. After cooking, cool to 45°C and add fried Wheat flour and fried wheat flour are fried by a wheat frying machine at 150°C for 20 seconds in advance, and then crushed through a 40-mesh sieve to obtain fried wheat flour; add 0.3% of Aspergillus oryzae seed koji, and send it to the koji making machine at a temperature of 35°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com