Plastic-steel winding pipe production line

A technology for plastic-steel winding pipes and production lines, which is applied to tubular articles, applications, laser welding equipment, etc., can solve the problems of the distance between the laser knife and the pipe, reduce the strength of the laser knife, and reduce the cutting effect of the cutting device, so as to improve the cutting effect and improve the use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

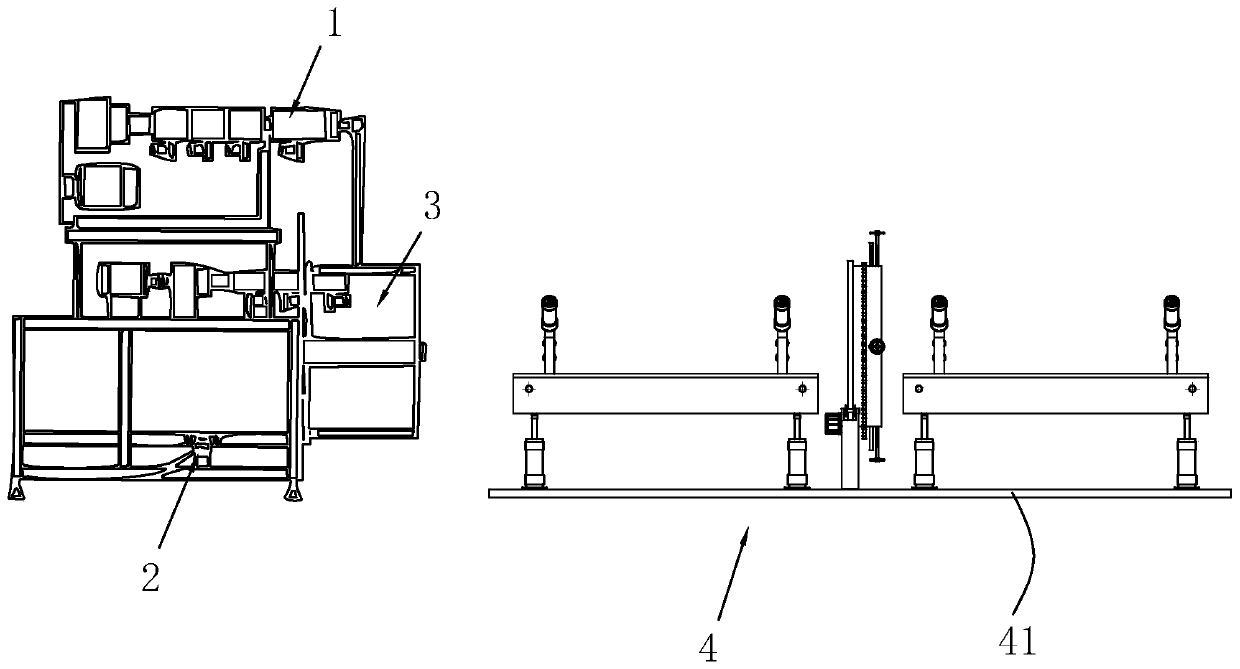

[0034] refer to figure 1, is a plastic-steel winding pipe production line disclosed in the present invention, comprising a glue applicator 1, a glue machine 2, a winding machine 3 and a cutting device 4 arranged in sequence, the cutting device 4 includes a base plate 41, and the base plate 41 is provided with two The end-to-end conveying device; the gluing machine 1, the gluing machine 2, and the winding molding machine 3 are all prior art, and in this embodiment, their detailed structures will not be repeated.

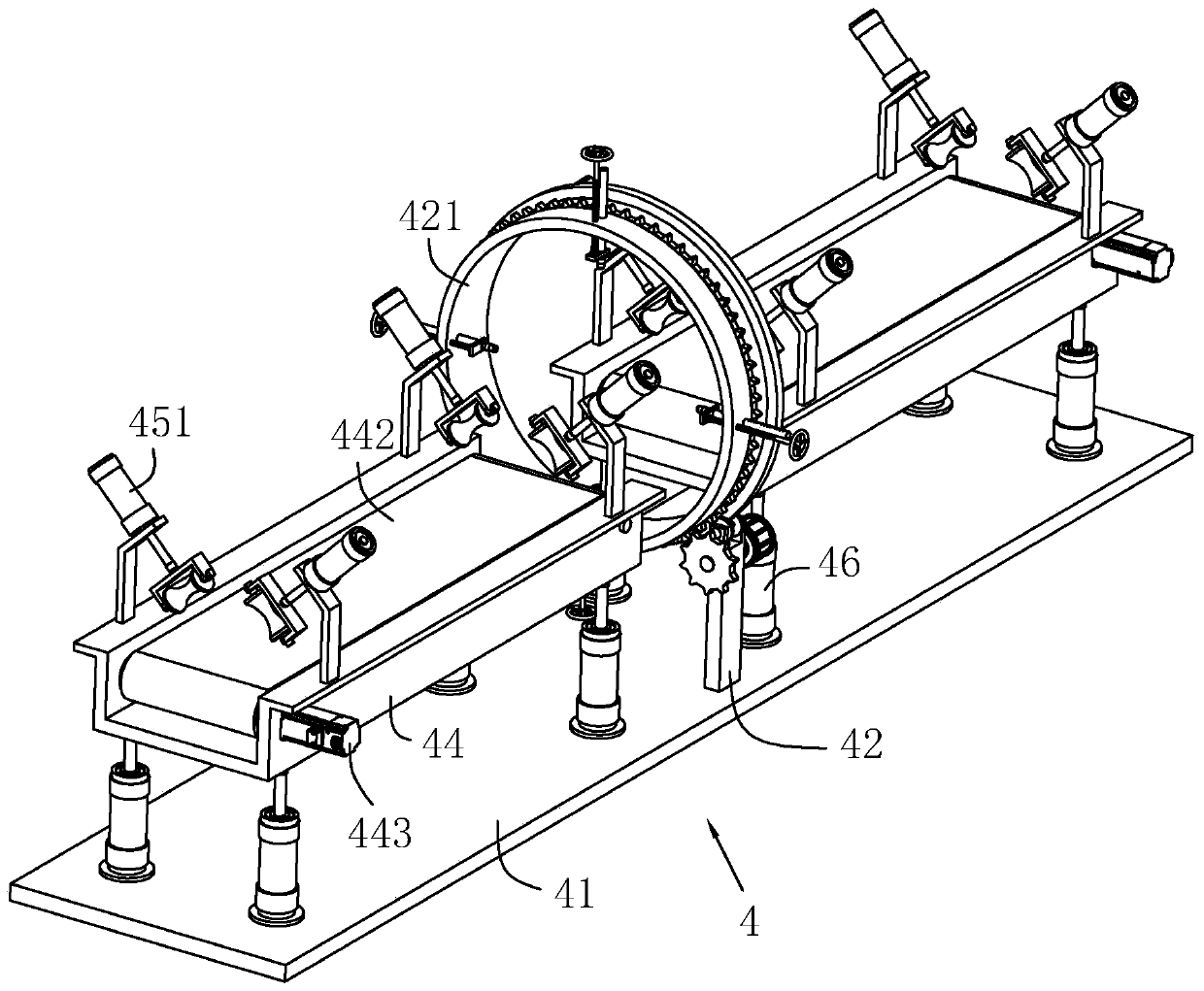

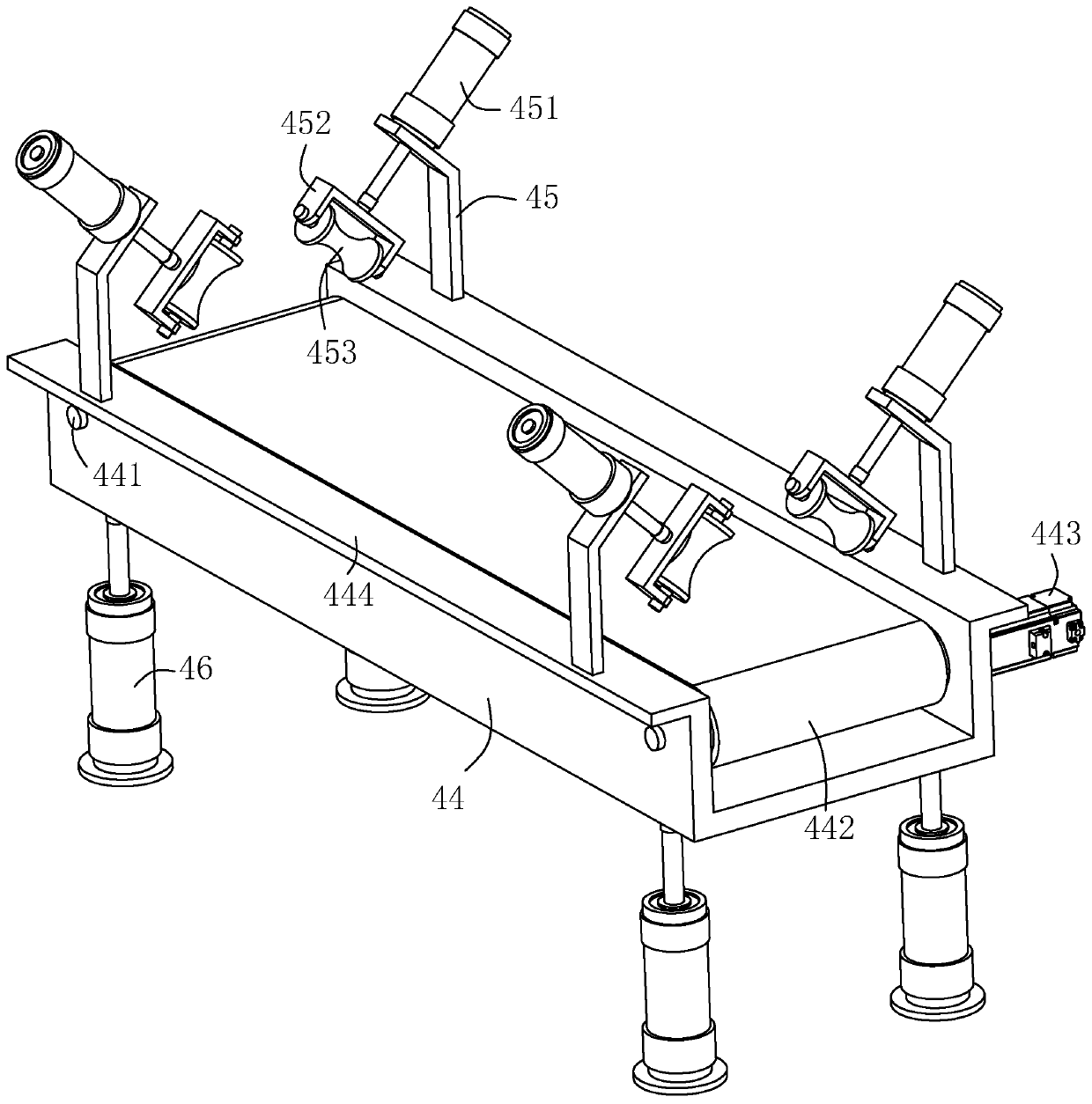

[0035] combine figure 2 and image 3 , the conveying devices all include a trough 44 with a "U" shape in cross section, the two ends of the trough 44 are located in the trough 44 and are connected to a rotating shaft 441 across and rotatably connected, and a conveyor belt is wound around the rotating shaft 441 on both sides. 442 , a second motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com