Sludge collection system of sewage treatment biochemical tank

A collection system and sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc. Problems such as troublesome operation and maintenance, to solve the problem of sludge collection, prevent sludge from clogging the pipeline, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

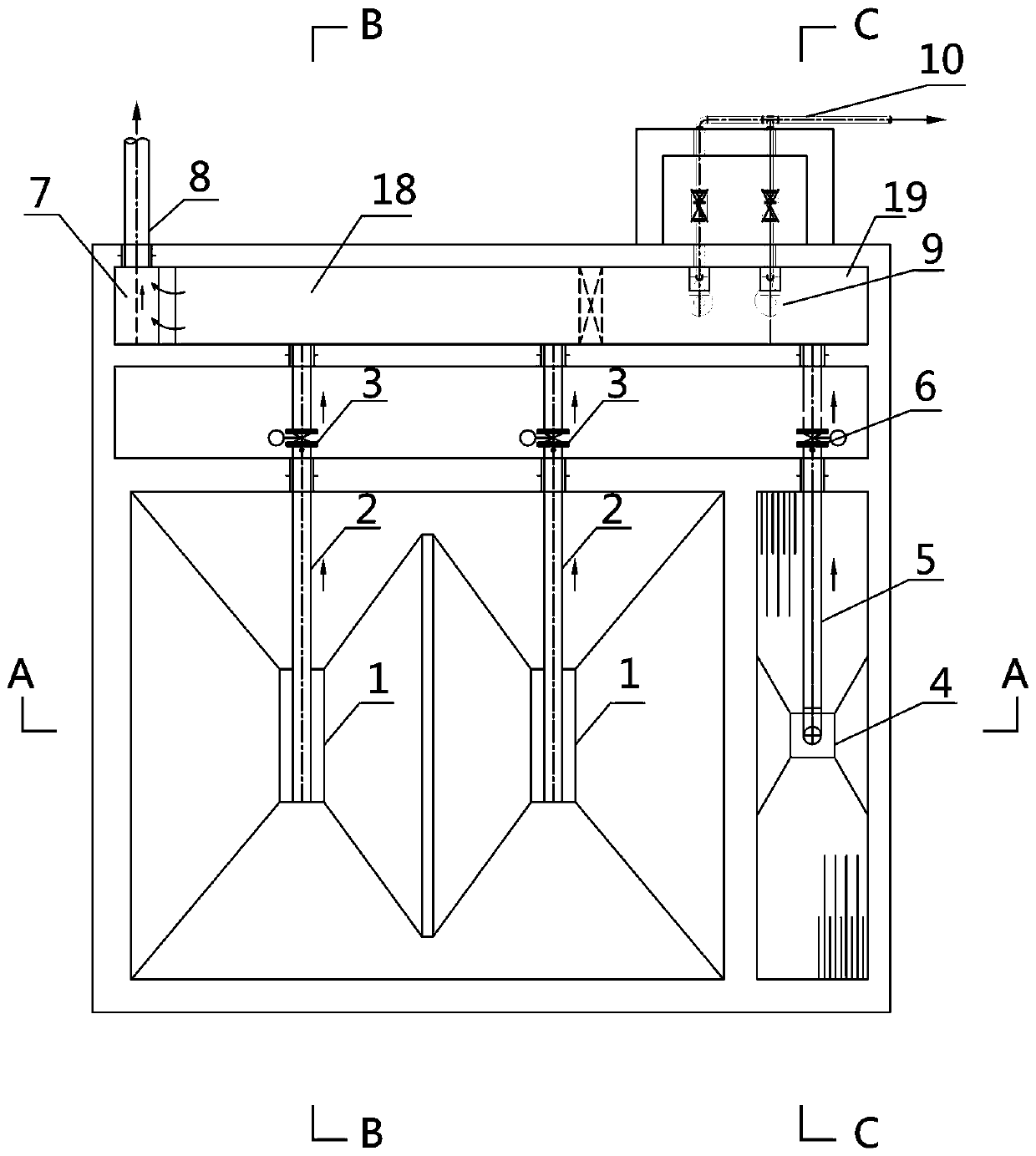

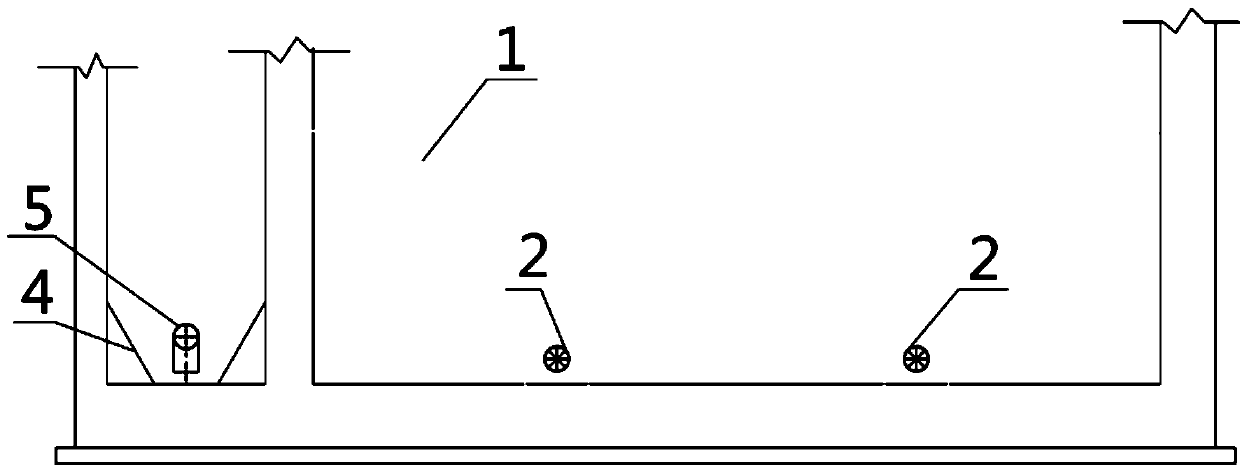

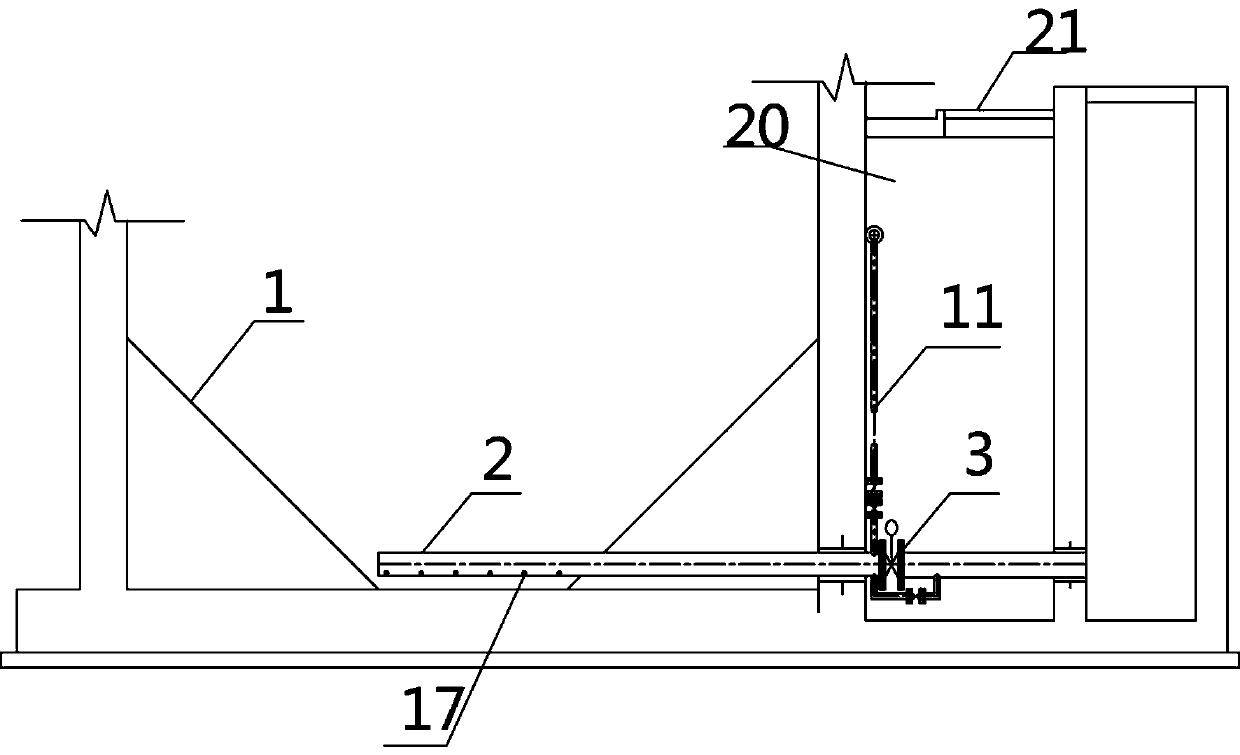

[0028] The preferred solution is as Figure 1 to Figure 6 As shown, the sewage treatment biochemical tank sludge collection system includes a sedimentation tank and a clarifier. The bottom of the sedimentation tank is provided with a sedimentation tank sludge collection mud bucket 1, and the bottom of the clarification tank is provided with a clarification tank sludge collection mud bucket 4; There is a perforated mud discharge pipe 2 at the bottom of the mud collection hopper 1, one end of the perforated mud discharge pipe 2 is connected with the sludge collection hopper 1 of the sedimentation tank, the other end of the perforated mud discharge pipe 2 is connected with the return sludge tank 18, and the perforated mud discharge pipe 2 There are several holes 17 in the part located in the sludge collection bucket 1 of the sedimentation tank; the bottom of the sludge collection bucket 4 in the clarification tank is provided with a mud discharge pipe 5, and one end of the sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com