Oil injector

A technology of oil injector and oil filling plug, which is applied in the direction of machines/engines, liquid displacement machinery, variable displacement pump components, etc., to achieve the effects of adjustable oil injection, compact structure and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

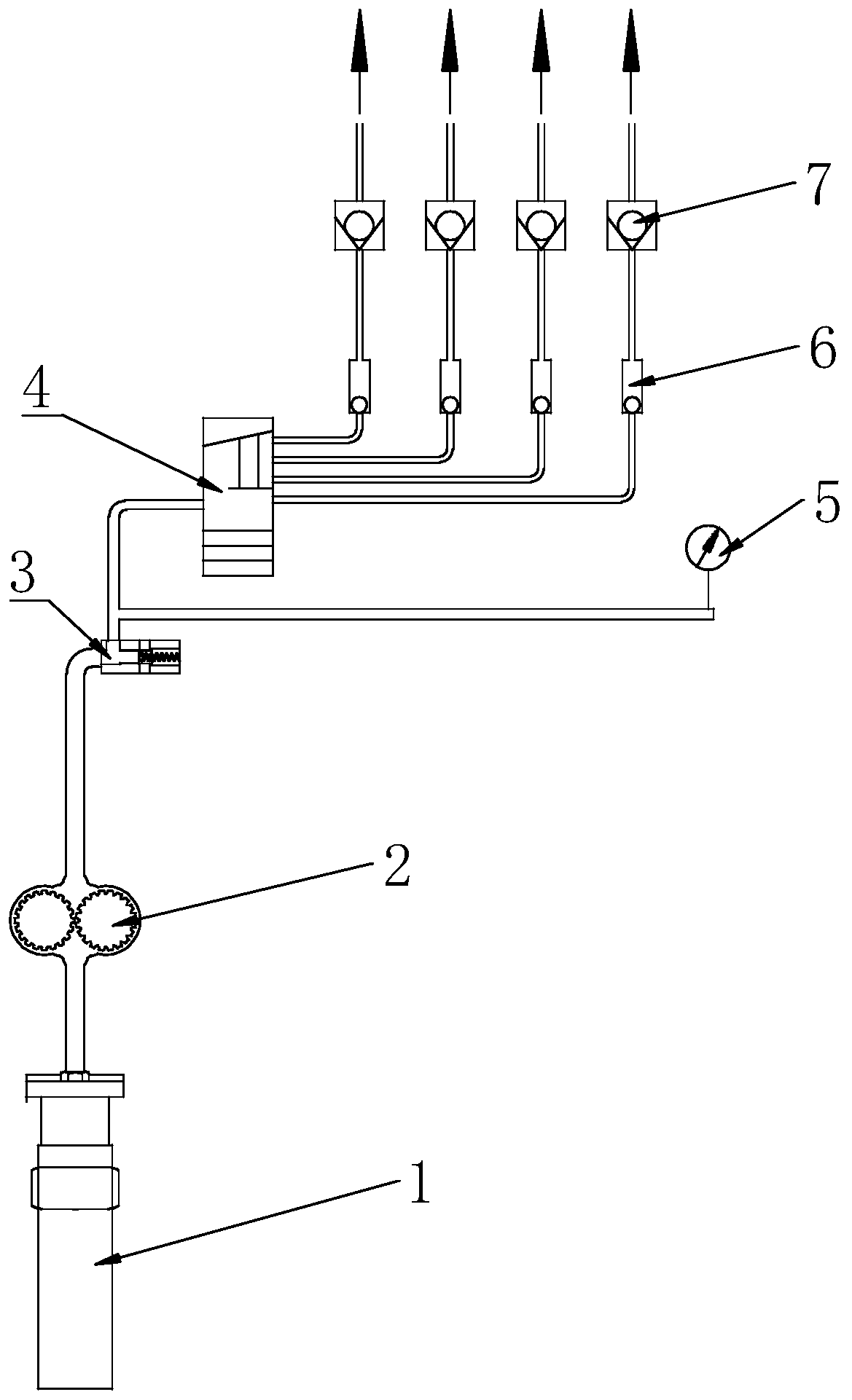

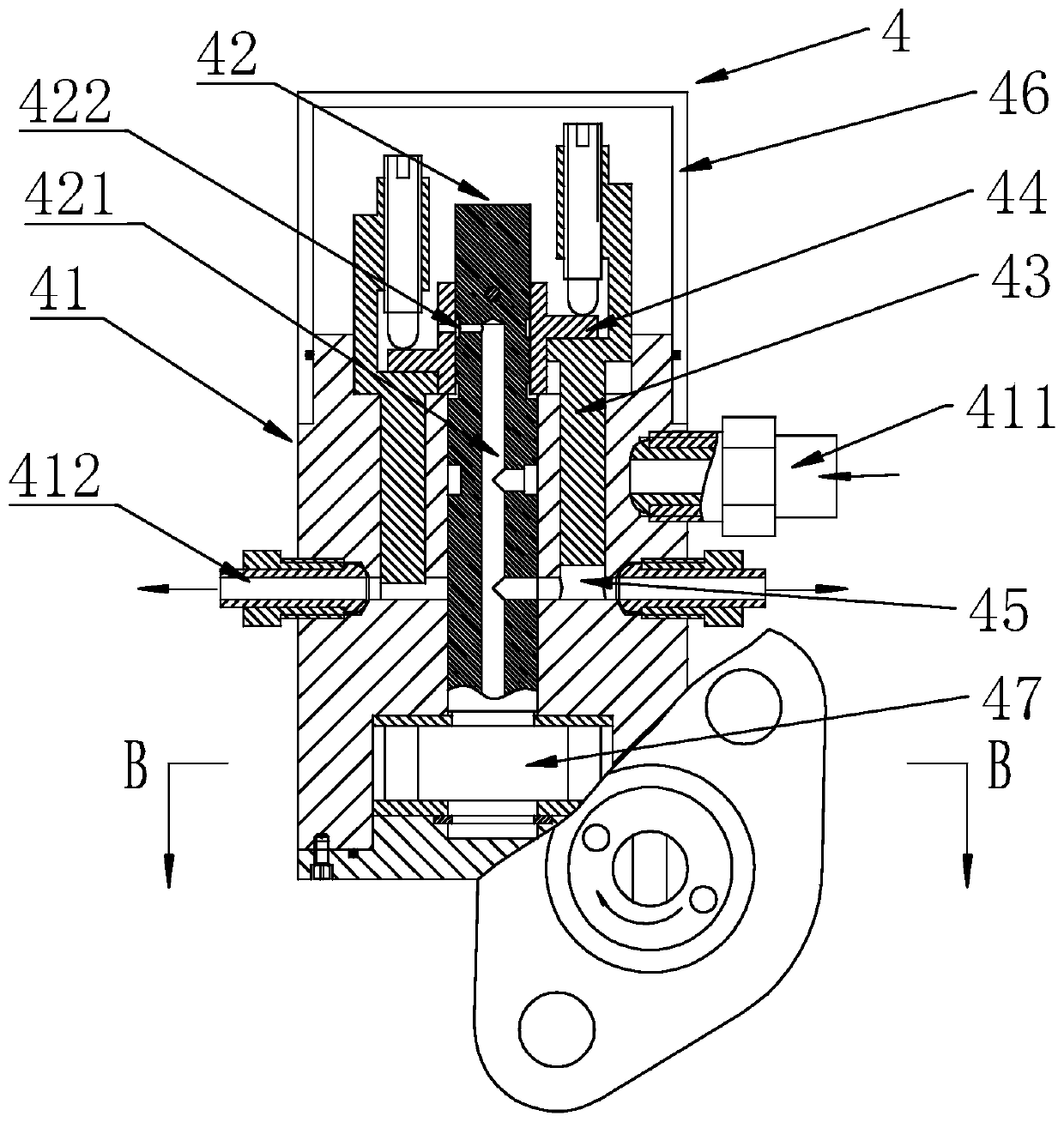

[0038] Such as figure 1 As shown, the compressor lubrication system includes a gear pump 2, an oil injector 4, a pressure limiting valve 3 and an oil filter 1; one end of the oil inlet of the oil filter 1 is connected below the liquid level of the oil tank; the gear pump 2 The oil inlet is connected with the oil outlet of the oil filter 1 through the oil passage, the oil outlet of the gear pump 2 is connected with the oil inlet of the pressure limiting valve 3 through the oil passage; the oil inlet of the oil injector 4 is connected through the The oil passage is connected with the oil outlet of the pressure limiting valve 3, and the lubricating oil derived from the oil outlet of the lubricator 4 enters the compressor through the passage.

Embodiment 2

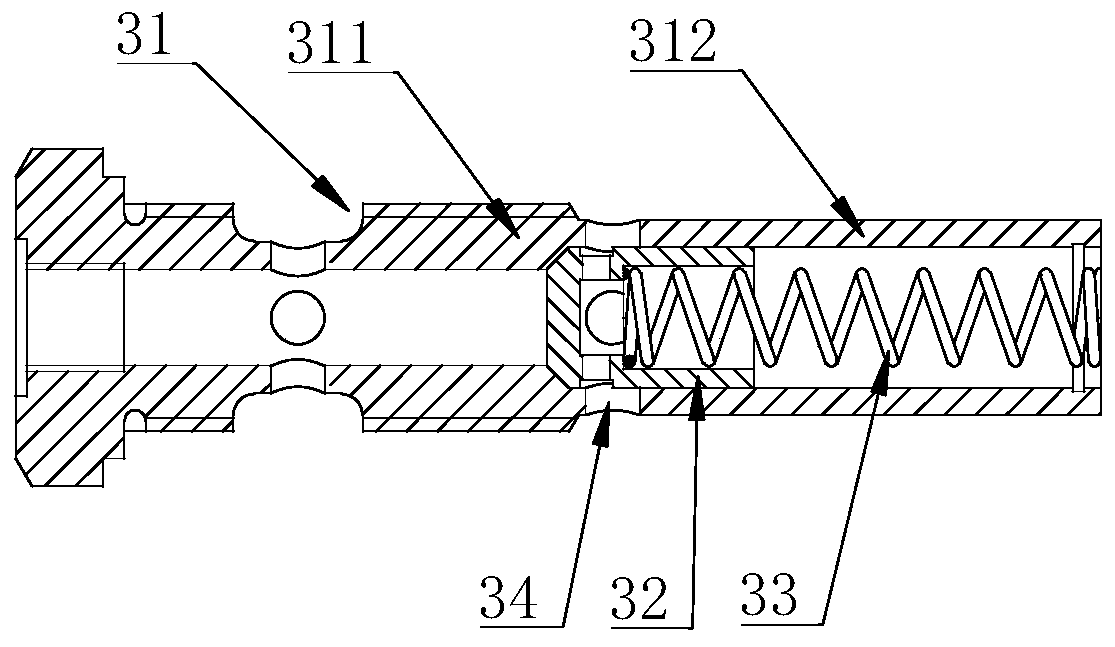

[0040] On the basis of Example 1, such as figure 2 As shown, the pressure limiting valve 3 includes a valve body 31, a limit piston 32 and an elastic device 33; the valve body 31 includes an integrated oil guide section 311 and an oil unloading section 312; the oil guide section 311 is provided with Conducting the first oil passage of the oil inlet and the oil outlet of the pressure limiting valve 3; the inside of the oil unloading section 312 is provided with a cavity, and the wall of the cavity is provided with a penetrating oil unloading port 34, and the inside of the cavity A limit piston 32 is provided; the limit piston 32 is arranged close to the oil guide section 311, and one end of the limit piston 32 away from the oil guide section 311 is provided for blocking the limit piston in the second position under the set oil pressure. In an oil passage, there is an elastic force device 33 for blocking the flow. When the internal pressure of the valve body 31 is lower than t...

Embodiment 3

[0042] On the basis of Embodiment 1, the compressor lubrication system also includes a pressure gauge 5, an oil sight glass 6 and a one-way valve 7; the one-way valve 7 is arranged between the oiler 4 and the compressor, and is used for 4 is one-way conduction in the direction of the compressor; the oil sight glass 6 is set between the oiler 4 and the one-way valve 7; the pressure gauge 5 is set between the pressure limiting valve 3 and the oiler 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com