Energy-saving and environment-friendly sound production device for sound-wave dust removal of boiler discharge flue and application method

An energy-saving, environmental-friendly, and sound-generating device technology, which is applied to cleaning methods and appliances, combustion methods, chemical instruments and methods, etc., can solve the problems of low sounding efficiency, insufficient energy saving and environmental protection, and height adjustment, so as to improve the effect of cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

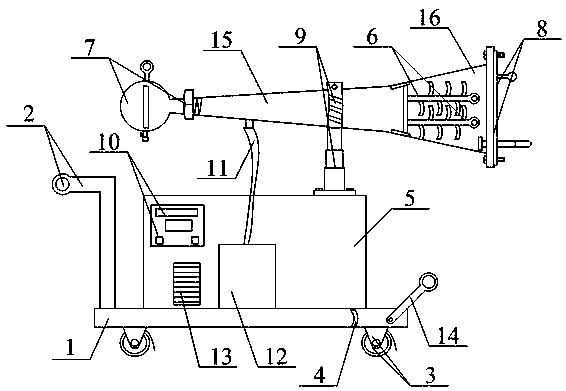

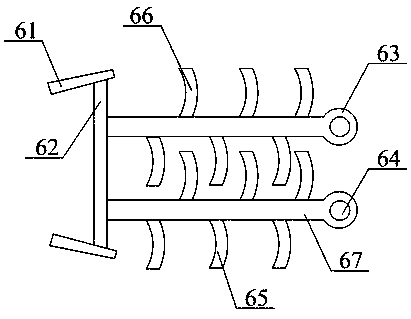

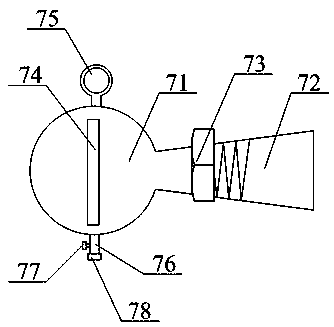

[0043] as attached figure 1 to attach figure 2 As shown, the present invention provides an energy-saving and environment-friendly sound-generating device for boiler flue sonic cleaning, which includes a mobile support tray 1, a push handle 2, a moving wheel 3, a fixed card 4, and a dust-cleaning box 5, which are convenient for fixing and cleaning. Gray sounding sheet structure 6, pressure stabilizing box structure for guiding waste liquid 7, sampling boiler exhaust pipe connection flange structure 8, liftable sound guiding cylinder supporting hoop structure 9, energy-saving sounding control box structure 10. Air guide rubber hose 11, air compressor 12, air vent 13, traction hanging plate 14, sounding air guide tube 15 and trumpet-shaped stainless steel tube 16, the push handle 2 is bolted to the mobile support tray 1 The position on the left side of the surface; the moving wheels 3 are respectively bolted to the four corners of the lower surface of the mobile support tray 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com