Solar energy low voltage carbon fiber ground heating system

A low-voltage, carbon fiber technology, applied in the field of solar energy utilization, can solve the problems of complicated installation, easy leakage and injury, high energy consumption of electric floor heating, and achieve the effect of reducing heating costs, energy consumption and heating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing,

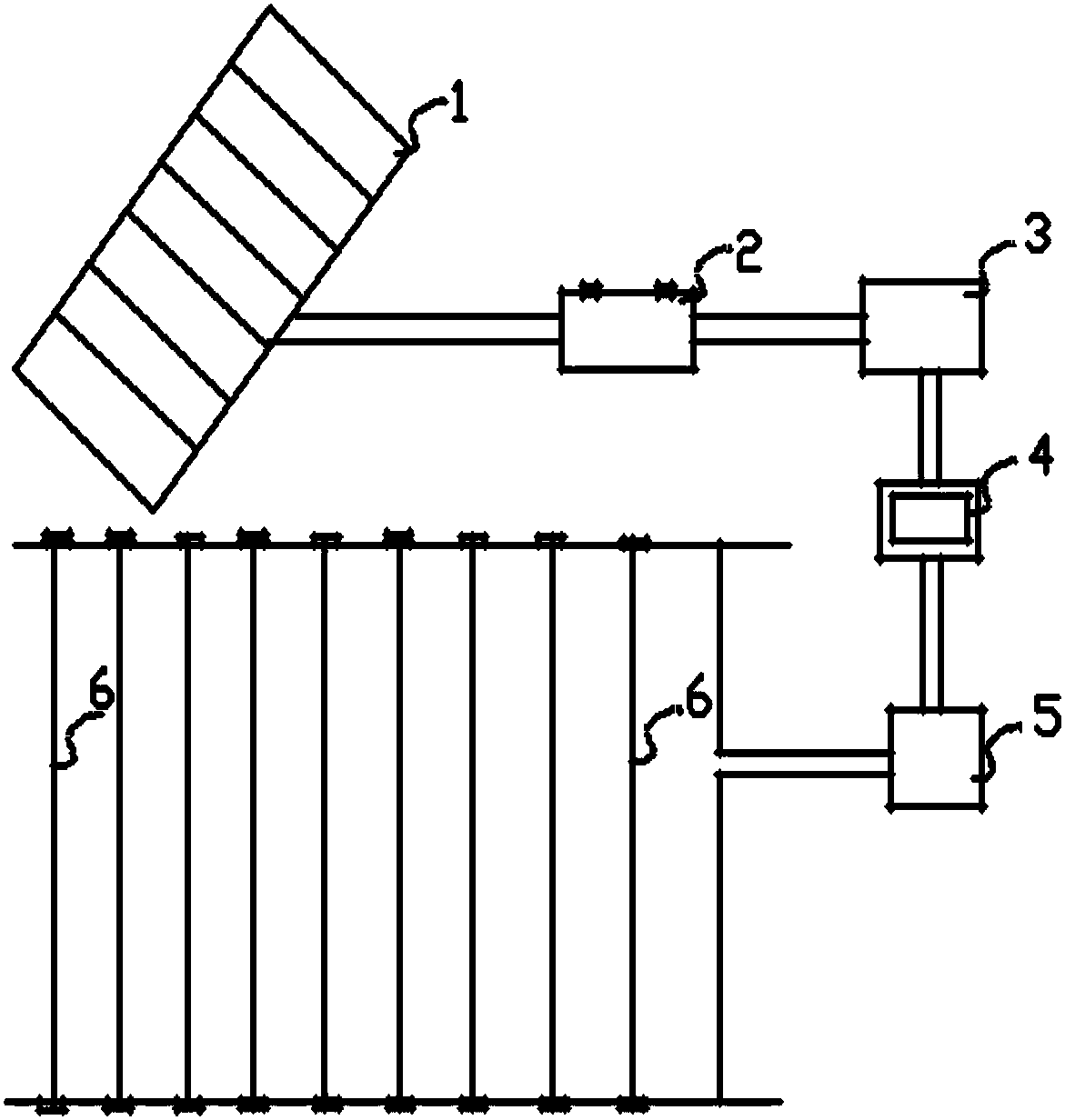

[0015] Such as figure 1 As shown, the present invention is a solar low-voltage carbon fiber floor heating system, including a solar photovoltaic panel 1, a storage battery 2, an inverter 3, a temperature controller 4, a transformer 5, and a track-type carbon fiber heating wire 6; The photovoltaic panel 1 is connected to the battery 2;

[0016] The storage battery 2 is connected with the inverter 3;

[0017] The inverter 3 is connected with a temperature controller 4; the temperature controller 4 is connected with a transformer 5; the transformer 5 is connected 6 with a track-type carbon fiber heating wire.

[0018] Among them, the storage battery 2 is a lithium-ion battery pack; the rail-type carbon fiber heating 6-wire specification is 12K, and the length of each group of carbon fiber heating wires is 0.8m-1.2m, and multiple sets of carbon fiber heating wires are connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com