Method for dry-method synthesis of zinc acetylacetonate under normal pressure

A technology of zinc acetylacetonate and acetylacetonate, applied in the field of preparation of zinc acetylacetonate, can solve the problems of high energy consumption, complex process, and many waste water, and achieve the effects of low energy consumption, simple operation, and no waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

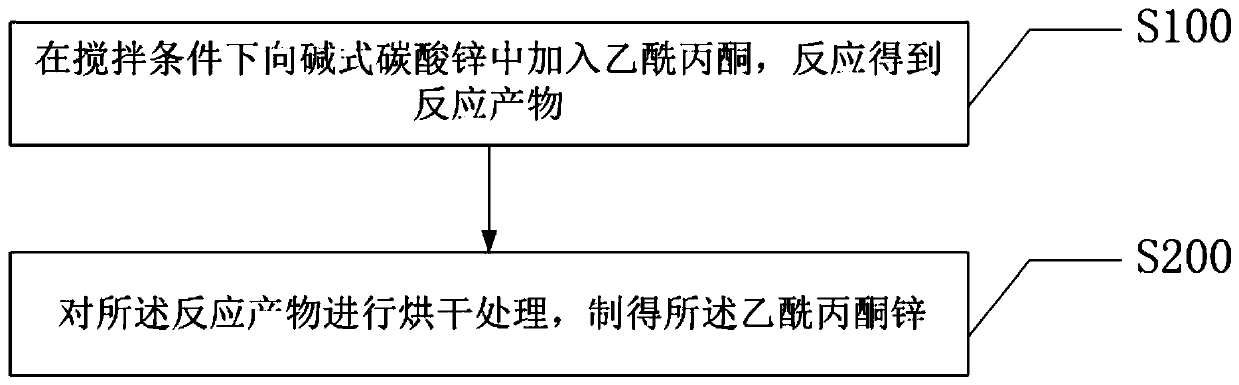

Method used

Image

Examples

Embodiment 1

[0039] Weigh 100g of acetylacetone and pour it into the dropping funnel, then weigh 55g of basic zinc carbonate and pour it into the stirrer, initially set the stirrer at 500rpm, turn on the switch of the dropping funnel, and let the acetylacetone drop down. The reaction proceeds rapidly, and carbon dioxide escapes immediately, which will bring up basic zinc carbonate powder. With the dropwise addition of acetylacetone, more and more zinc acetylacetonate is produced. Increase the rotation speed to 2000rpm. After 30min, all the acetylacetone has been dropped, and continue to stir at 2000rpm for 20min. After the reaction, put the product into an oven for 1 hour at 100°C. The zinc content was measured by weighing, the product yield was 94.56%, and the zinc content was 24.36%.

Embodiment 2

[0041] Weigh 105g of acetylacetone and pour it into the dropping funnel, then weigh 56g of basic zinc carbonate and pour it into the stirrer, initially set the stirrer at 300rpm, turn on the switch of the dropping funnel, and let the acetylacetone drop down. The reaction proceeds rapidly, and carbon dioxide escapes immediately, which will bring up basic zinc carbonate powder. With the dropwise addition of acetylacetone, more and more zinc acetylacetonate is produced. Increase the rotation speed to 1500rpm. After 35min, all the acetylacetone has been dropped, and continue to stir at 2500rpm for 25min. After the reaction, put the product into an oven for 1 hour at 100°C. The zinc content was measured by weighing, and the product yield was 97.42%, and the zinc content was 25.24%.

Embodiment 3

[0043] Weigh 85g of acetylacetone and pour it into the dropping funnel, then weigh 45g of basic zinc carbonate and pour it into the stirrer, initially set the stirrer at 500rpm, turn on the switch of the dropping funnel, and let the acetylacetone drop down. The reaction proceeds rapidly, and carbon dioxide escapes immediately, which will bring up basic zinc carbonate powder. With the dropwise addition of acetylacetone, more and more zinc acetylacetonate is produced. Increase the rotation speed to 3000rpm. After 30 minutes, all the acetylacetone has been dropped, and continue to stir at a rotation speed of 3000rpm for 25 minutes. After the reaction, put the product into an oven for 1 hour at 100°C. The zinc content was measured by weighing, the product yield was 96.27%, and the zinc content was 24.98%.

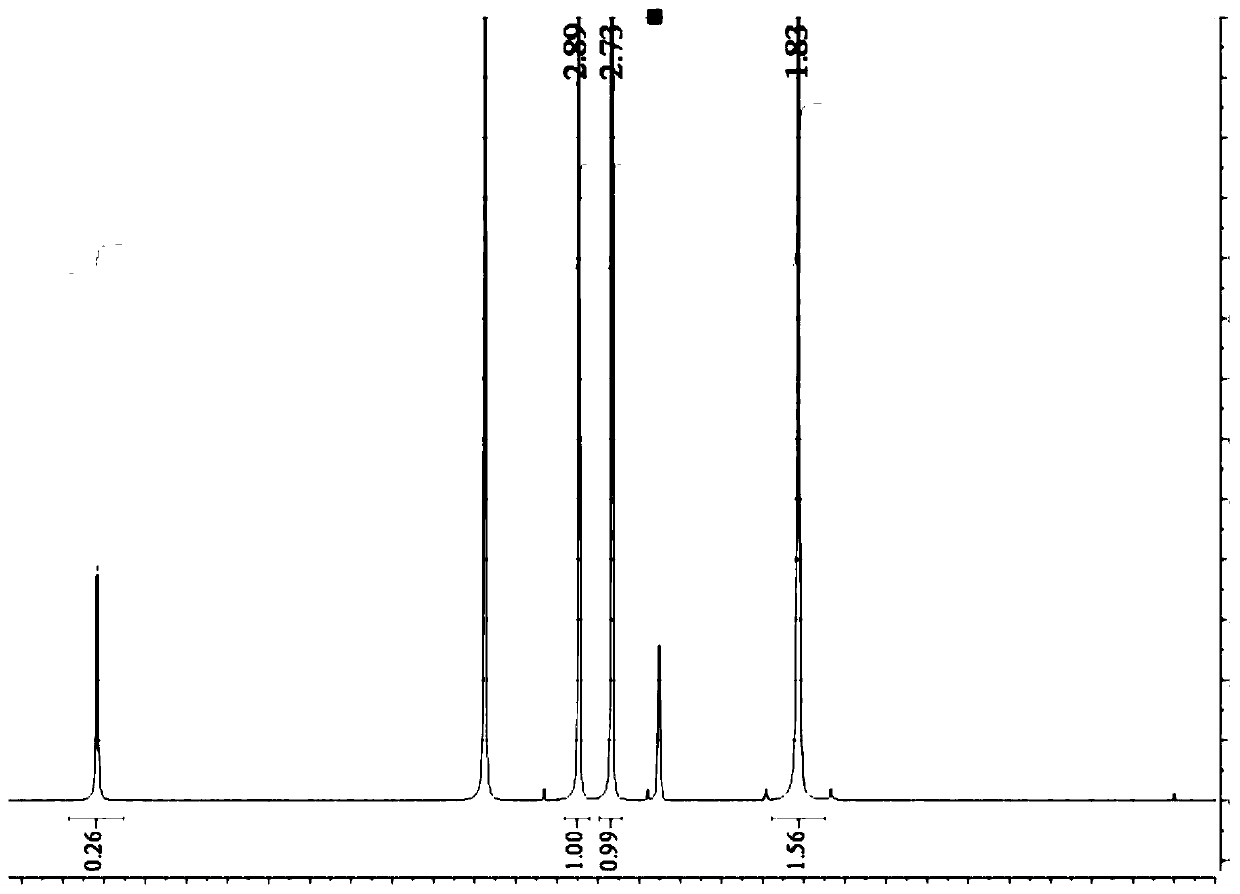

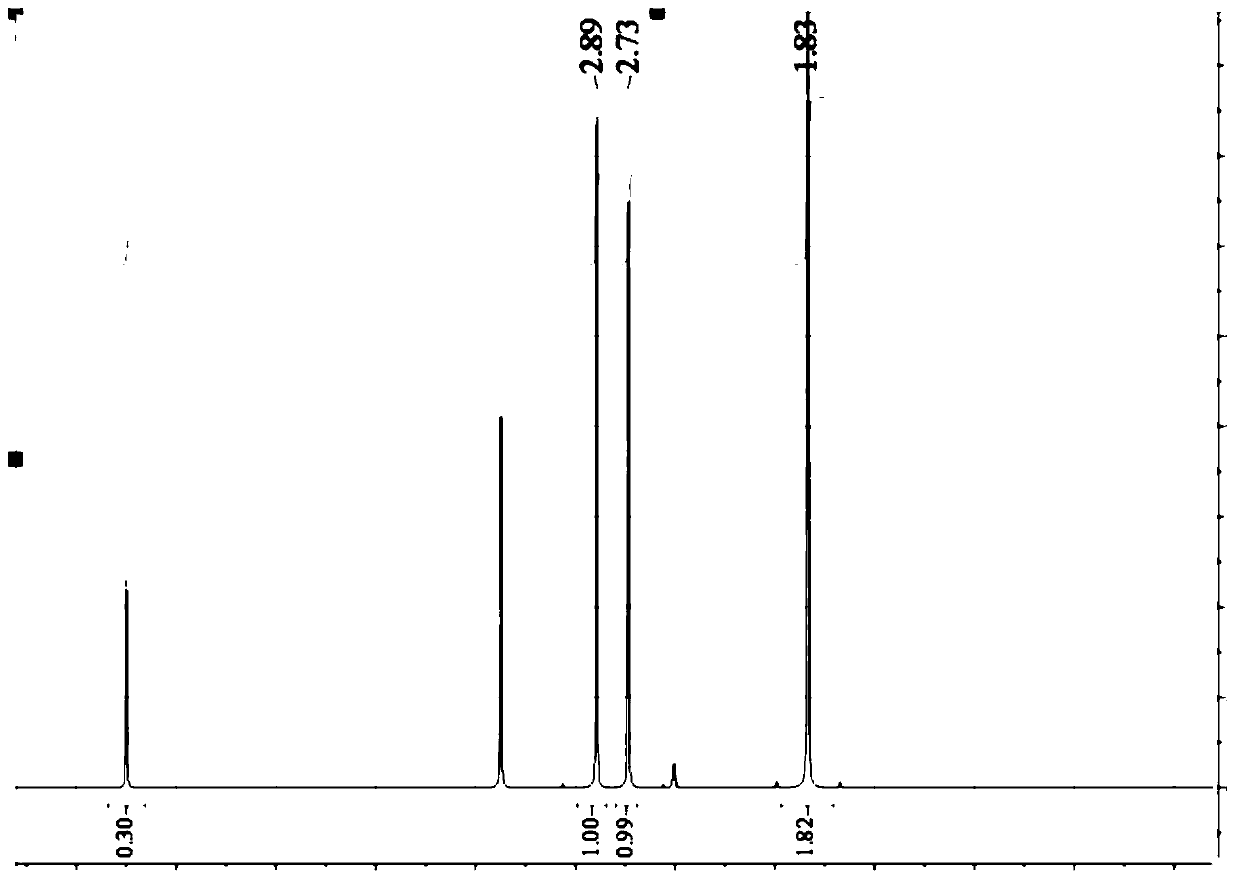

[0044] The product prepared in this embodiment 3 and the zinc acetylacetonate standard sample are carried out NMR (nuclear magnetic resonance) test respectively, and the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com