Z-N catalyst, preparation method and applications thereof

A catalyst, Z-N technology, applied in the field of Ziegler-Natta catalysts, can solve the problems of poor activity and isotacticity

- Summary

- Abstract

- Description

- Claims

- Application Information

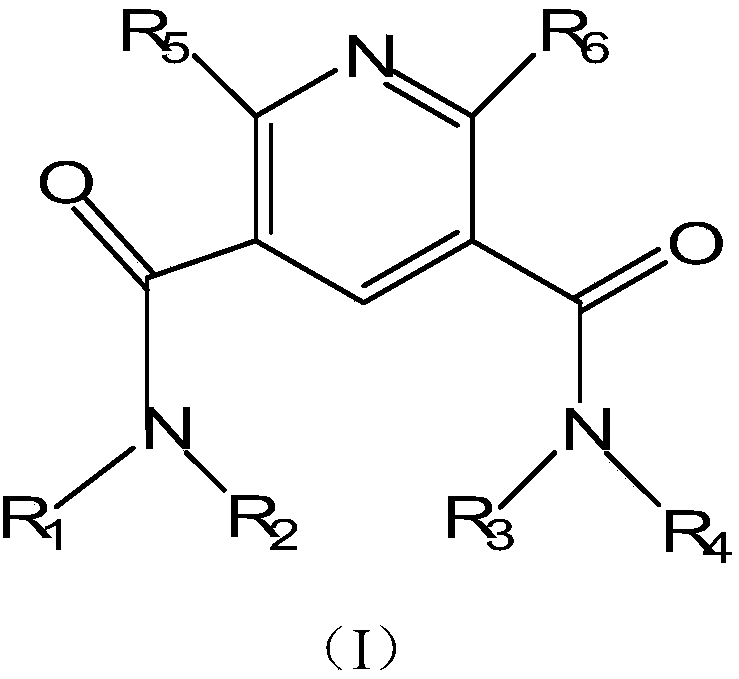

AI Technical Summary

Problems solved by technology

Method used

Image

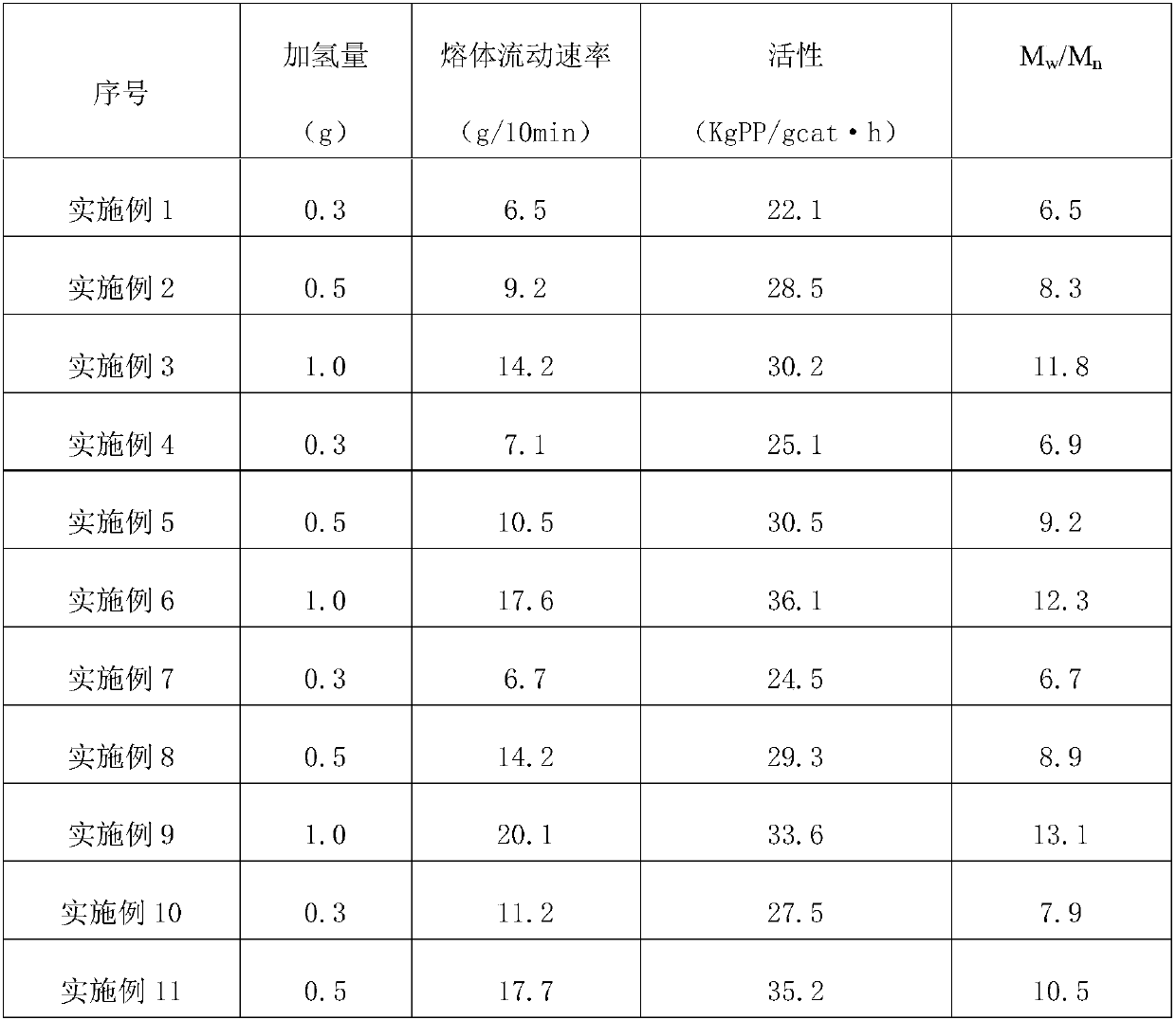

Examples

Embodiment 1

[0044] Preparation of the main catalyst: under anhydrous and oxygen-free conditions, the alcoholate particles of 5.0 grams of microspherical magnesium chloride (self-made, the preparation steps refer to CN1110281A, the average particle size is 50 μm, and the specific surface is 150-230m 2 / g, the molar ratio of alcohol to magnesium chloride content is 2.85:1, molecular formula: MgCl 2 ·2.85CH 3 CH 2 OH) was added to 140ml of titanium tetrachloride liquid at -20°C, and after reacting for 1 hour, the temperature was gradually raised to 60°C; 1.03 g of 3,5-pyridine-(N,N'-di-n-butyl)diamide was added, Gradually raise the temperature to 120°C, react for 2 hours, and filter; then add 140ml of titanium tetrachloride, react at 120°C for 1 hour, and filter. Wash 5 times with 100ml hexane at 60°C, wash once with 30ml hexane at room temperature, and dry in vacuo to obtain the main catalyst.

[0045] The content of each component in the main catalyst is shown in Table 1.

[0046] Bulk...

Embodiment 2

[0049] Preparation of the main catalyst: under anhydrous and oxygen-free conditions, the alcoholate particles of 5.0 grams of microspherical magnesium chloride (self-made, the preparation steps refer to CN1110281A, the average particle size is 50 μm, and the specific surface is 150-230m 2 / g, the molar ratio of alcohol to magnesium chloride content is 2.85:1, molecular formula: MgCl 2 ·2.85CH 3 CH 2 OH) was added to 140ml of titanium tetrachloride liquid at -20°C, and after reacting for 1 hour, the temperature was gradually raised to 60°C; 1.03 g of 3,5-pyridine-(N,N'-di-n-butyl)diamide was added, Gradually raise the temperature to 120°C, react for 2 hours, and filter; then add 140ml of titanium tetrachloride, react at 120°C for 1 hour, and filter. Wash 5 times with 100ml hexane at 60°C, wash once with 30ml hexane at room temperature, and dry in vacuo to obtain the main catalyst.

[0050] The content of each component in the main catalyst is shown in Table 1.

[0051] Bulk...

Embodiment 3

[0054] Preparation of the main catalyst: under anhydrous and oxygen-free conditions, the alcoholate particles of 5.0 grams of microspherical magnesium chloride (self-made, the preparation steps refer to CN1110281A, the average particle size is 50 μm, and the specific surface is 150-230m 2 / g, the molar ratio of alcohol to magnesium chloride content is 2.85:1, molecular formula: MgCl 2 ·2.85CH 3 CH 2 OH) was added to 140ml of titanium tetrachloride liquid at -20°C, and after reacting for 1 hour, the temperature was gradually raised to 60°C; 1.03 g of 3,5-pyridine-(N,N'-di-n-butyl)diamide was added, Gradually raise the temperature to 120°C, react for 2 hours, and filter; then add 140ml of titanium tetrachloride, react at 120°C for 1 hour, and filter. Wash 5 times with 100ml hexane at 60°C, wash once with 30ml hexane at room temperature, and dry in vacuo to obtain the main catalyst.

[0055] The content of each component in the main catalyst is shown in Table 1.

[0056] Bulk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com