Preparation method of branched biodegradable polyester

A technology for biodegrading polyesters and compounds, applied in the field of polymers, can solve the problems of accelerating the aging speed of polyester materials, generating carboxyl groups, shortening the service life of polyester materials, etc., achieving low content of carboxyl groups and inhibiting the generation of carboxyl groups , Enhance the effect of melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

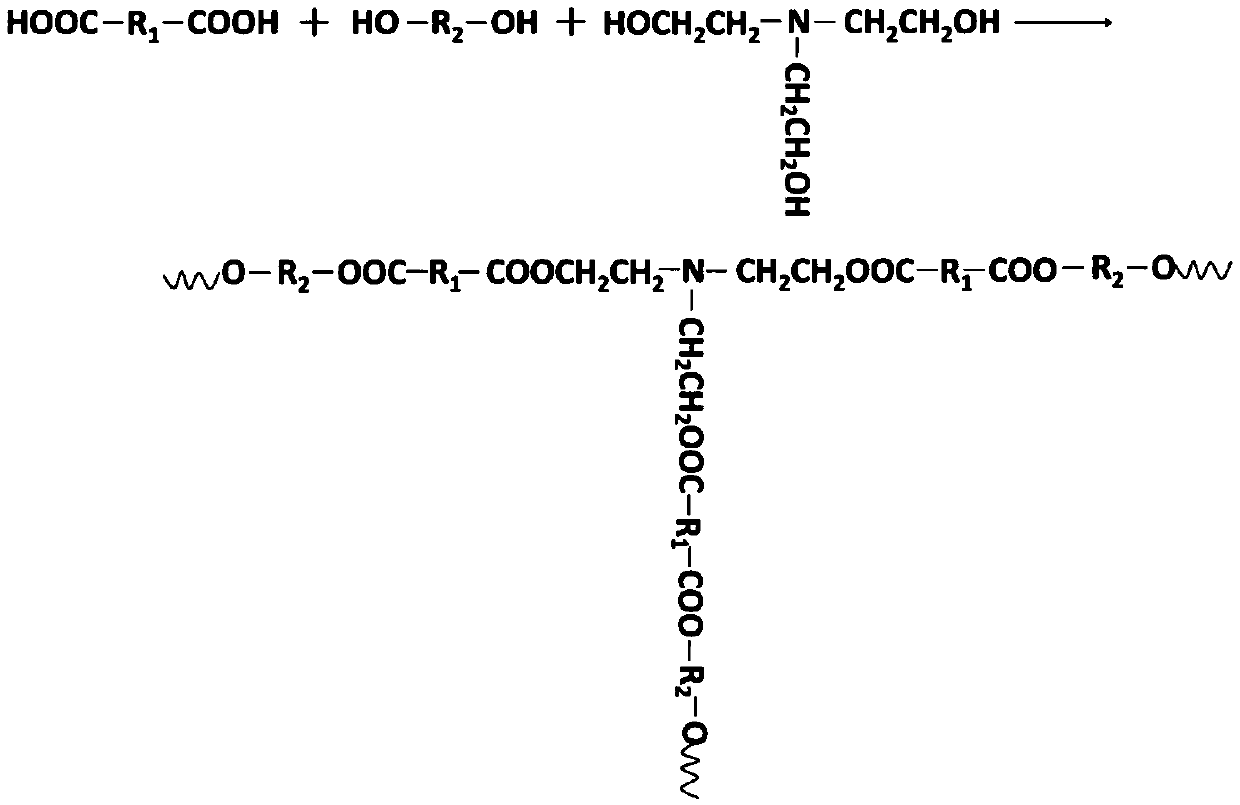

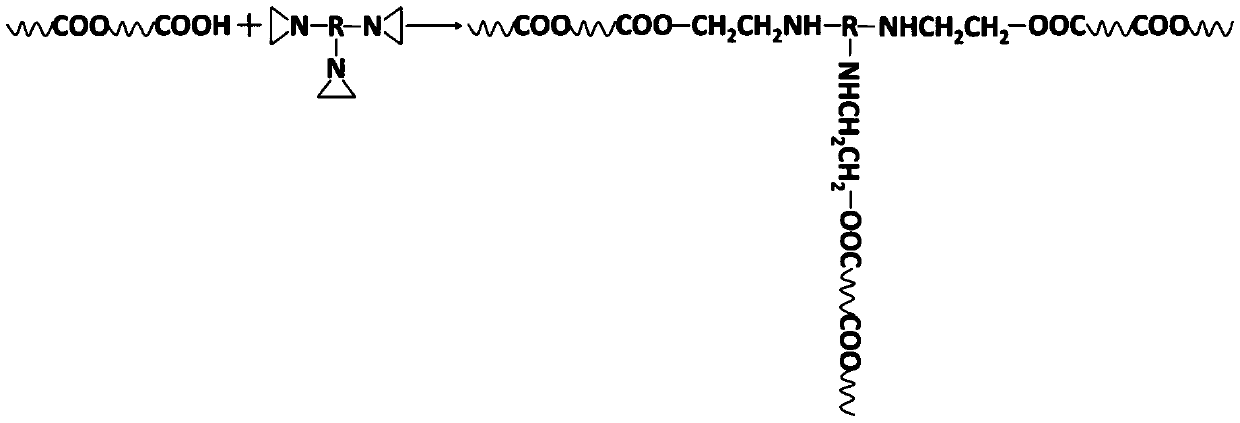

Method used

Image

Examples

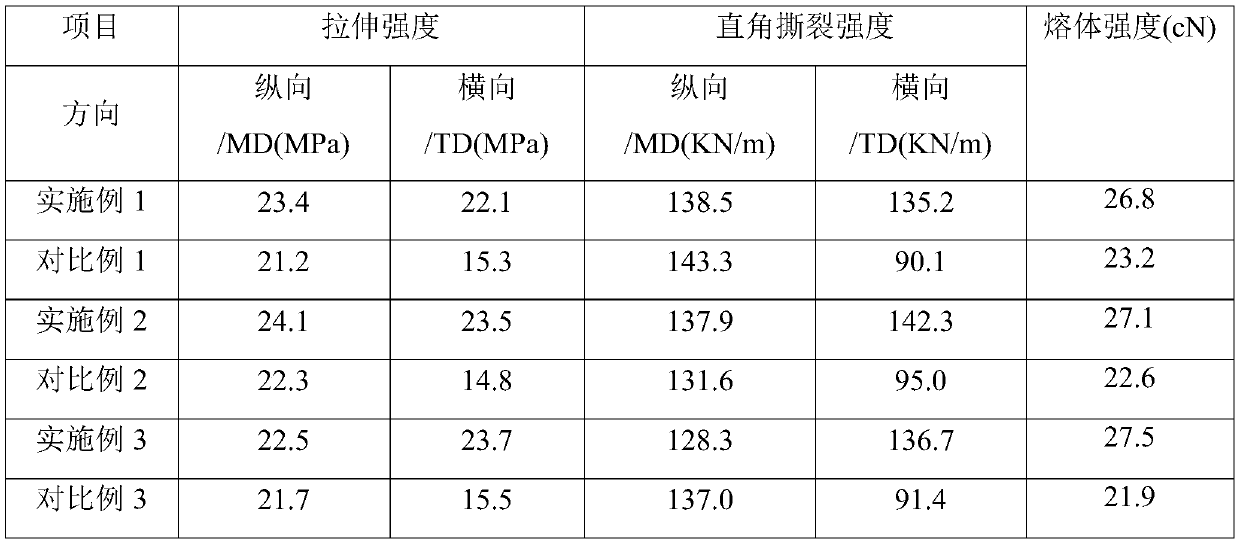

Embodiment 1

[0032] Add 18kg of 1,4-butanediol, 149g of triethanolamine, 7.47kg of terephthalic acid, 8.03kg of adipic acid, and 104.5g of germanium-based composite homogeneous catalysts into the reactor in sequence, stir and heat up to 220°C, and react for 1h Finally, add 45.2g of trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate, continue the reaction for 1.5h, then raise the temperature to 240°C, vacuumize to 30-80Pa, polycondensation reaction After 1.5 hours, a branched biodegradable polyester with a b value of 5, a carboxyl-terminal content of 22 mmol / kg and a molecular weight of 145,000 was obtained.

Embodiment 2

[0036] Add 9.9kg of 1,4-butanediol, 14.9g of triethanolamine, 6.64kg of terephthalic acid, 7.08kg of succinic acid, and 9.6g of germanium-based composite homogeneous catalysts to the reactor in sequence, and stir to raise the temperature to 220°C. After reacting for 2 hours, add 427.5g of pentaerythritol tris(3-aziridinyl) propionate, continue the reaction for 1 hour, then raise the temperature to 240°C, vacuumize to 30-80Pa, and polycondense for 2 hours to obtain branched biodegradable polyester , the b value is 6, the carboxyl-terminal content is 11 mmol / kg, and the molecular weight is 139,000.

Embodiment 3

[0040]Add 13.5kg of 1,3-butanediol, 74.5g of triethanolamine, 8.3kg of terephthalic acid, 7.3kg of adipic acid, and 63g of germanium-based composite homogeneous catalysts to the reactor in sequence, and stir to raise the temperature to 220°C. After 2h, add 212.8g of trimethylolpropane-tris(3-aziridinyl)propionate, continue the reaction for 1h, then raise the temperature to 240°C, vacuumize to 30-80Pa, polycondense for 2h, and obtain branched Biodegradable polyester with a b value of 6, a carboxyl-terminal content of 17 mmol / kg, and a molecular weight of 150,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com