Polyurethane foam material having skin-core structure, and preparation method thereof, and sealing material

A technology of polyurethane foam and skin-core structure, applied in the direction of coating, etc., can solve problems such as migration of additives, sealing failure, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

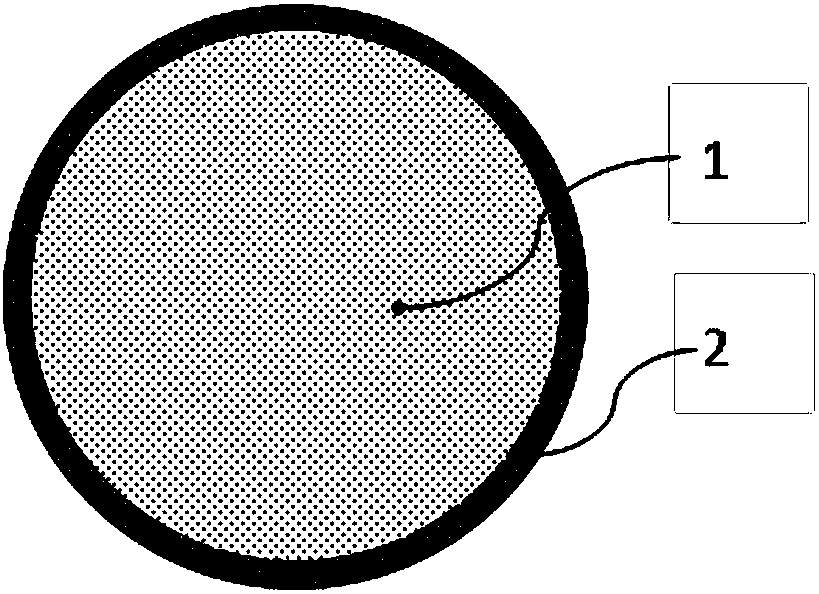

[0024] The second aspect of the present invention provides a method for preparing a polyurethane foam material with a skin-core structure. The method includes: coating a solution containing silicone rubber on the polyurethane foam, and then performing drying and curing treatments; The core foam formed by foam and the polyurethane foam material of the surface layer foam formed by silicone rubber modified polyurethane foam.

[0025] According to the present invention, the silicone rubber and polyurethane foam are as described above, and the present invention will not be repeated here.

[0026] According to the present invention, the concentration of the solution containing the silicone rubber can be varied within a wide range. Preferably, the concentration of the solution containing the silicone rubber is 15-60% by weight, preferably 20-50% by weight, It is more preferably 30-40% by weight, especially by controlling the viscosity of the silicone rubber-containing solution to 2000-100...

Embodiment 1

[0045] This embodiment is used to illustrate the polyurethane foam material with a skin-core structure and its preparation method and sealing material of the present invention.

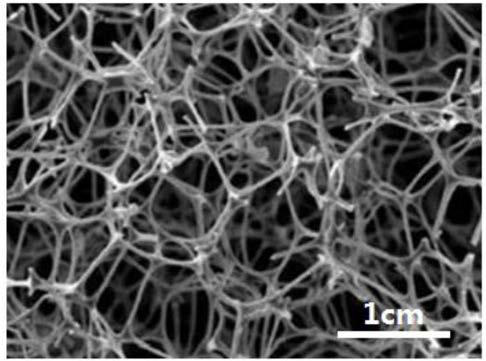

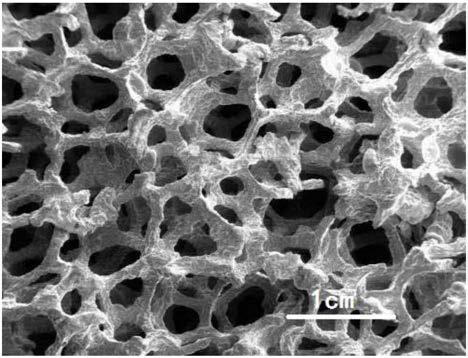

[0046] (1) Dissolve polydimethylsiloxane in xylene and pass a 100 mesh filter to obtain a silicone rubber solution with a polydimethylsiloxane content of 30% by weight (viscosity 350cp); Method (spraying pressure 0.35-0.40MPa, spraying distance is about 150mm) spray the silicone rubber solution on the surface of cylindrical polyurethane foam (outer diameter 20cm, apparent density 35g / cm 3 , See the SEM image of the surface figure 2 ), after spraying (the infiltration depth of the silicone rubber solution is about 10mm), place it in a vacuum oven at 80℃ for 3min, take it out and cure for 24h at a relative humidity of 35% and a temperature of 20℃ to obtain a polyurethane foam with a skin-core structure Material P1, its outer diameter is 20cm, apparent density is 45g / cm 3 , The thickness ratio of the surfac...

Embodiment 2

[0050] This embodiment is used to illustrate the polyurethane foam material of the skin-core structure of the present invention, its preparation method and sealing material.

[0051] (1) Dissolve polydimethylsiloxane in ethyl acetate and pass a 100-mesh filter to obtain a silicone rubber solution with a polydimethylsiloxane content of 40% by weight (viscosity 420cp); spin spraying Method (spraying pressure 0.35-0.40MPa, spraying distance is about 180mm) spray the silicone rubber solution on the surface of cylindrical polyurethane foam (outer diameter is 18cm, apparent density 40g / cm 3 ), after spraying (the infiltration depth of the silicone rubber solution is about 15mm), dry it in a vacuum oven at 100℃ for 5min, take it out and cure it for 30h at a relative humidity of 40% and a temperature of 25℃ to obtain a polyurethane foam with a skin-core structure Material P2, its outer diameter is 18cm, apparent density is 53g / cm 3 , The thickness ratio of the surface layer foam and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com