Method for manufacturing semiconductor devices

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as separation, and achieve the effect of improving adhesion, reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

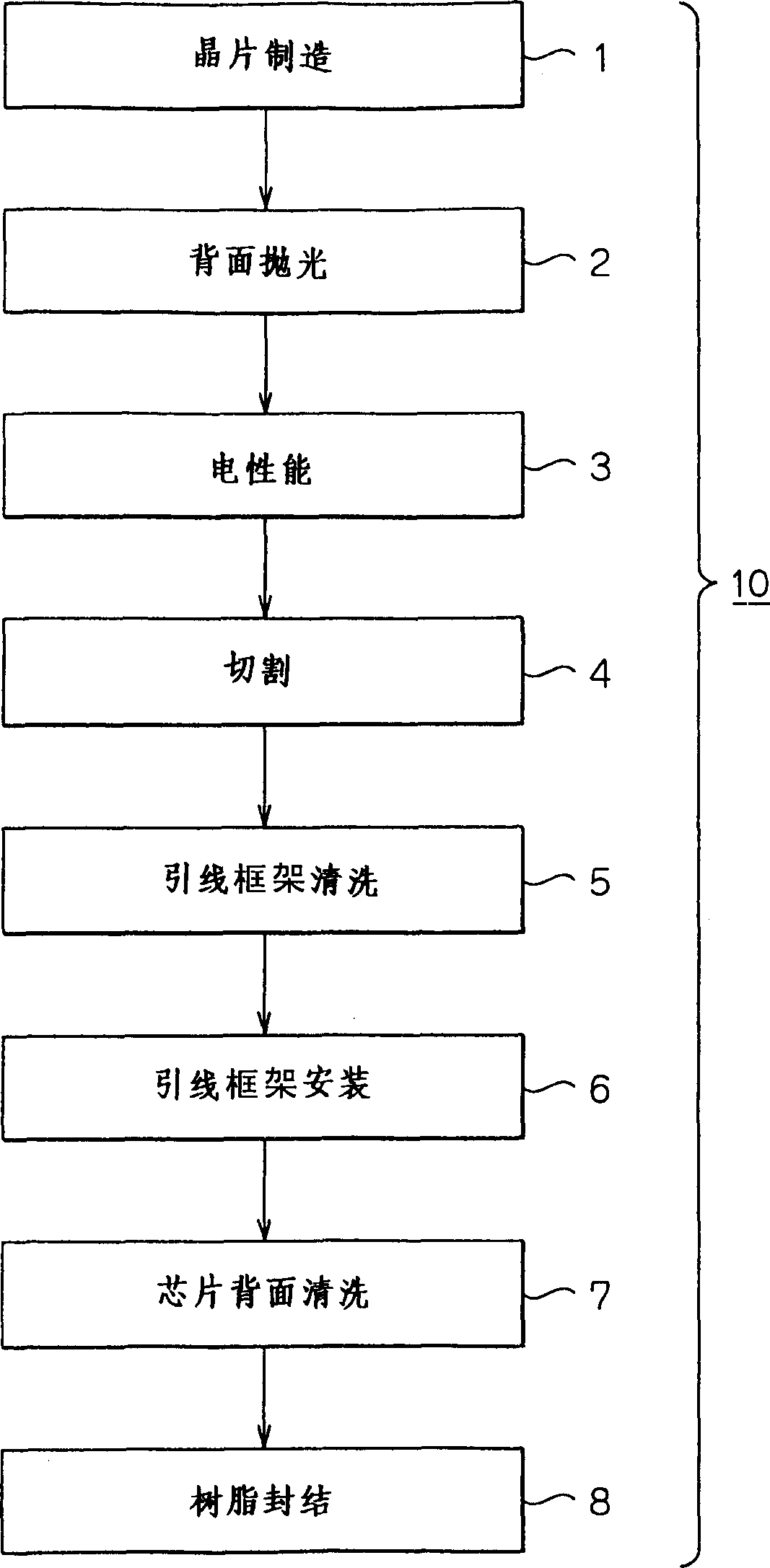

[0037] figure 1 is a flowchart of the manufacturing method 10 of the semiconductor device 11 . The manufacturing method 10 includes the following steps: a wafer manufacturing process 1, a backside polishing process 2, an electrical property measurement process 3, a cutting process 4, a lead frame cleaning process 5, a lead frame mounting process 6, a chip back cleaning process 7, and resin sealing Process 8. Perform the above process in the order shown in the figure.

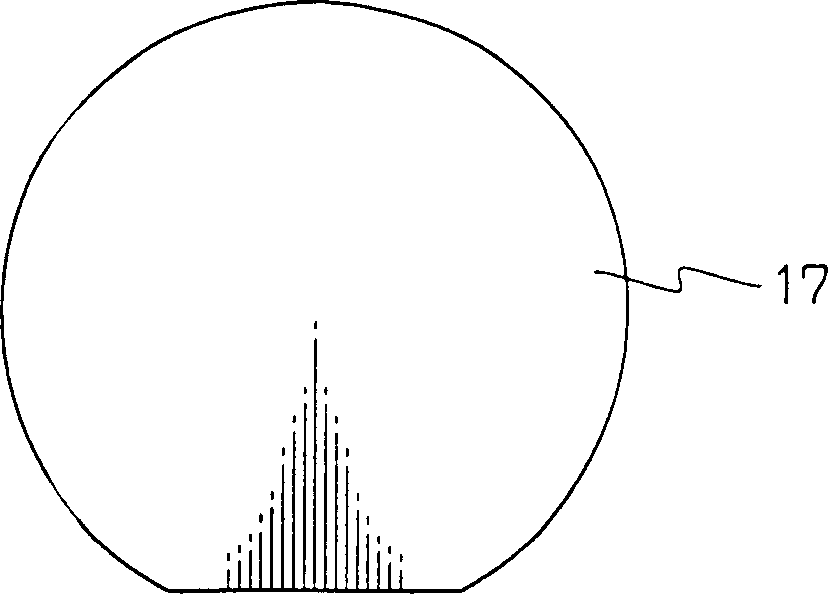

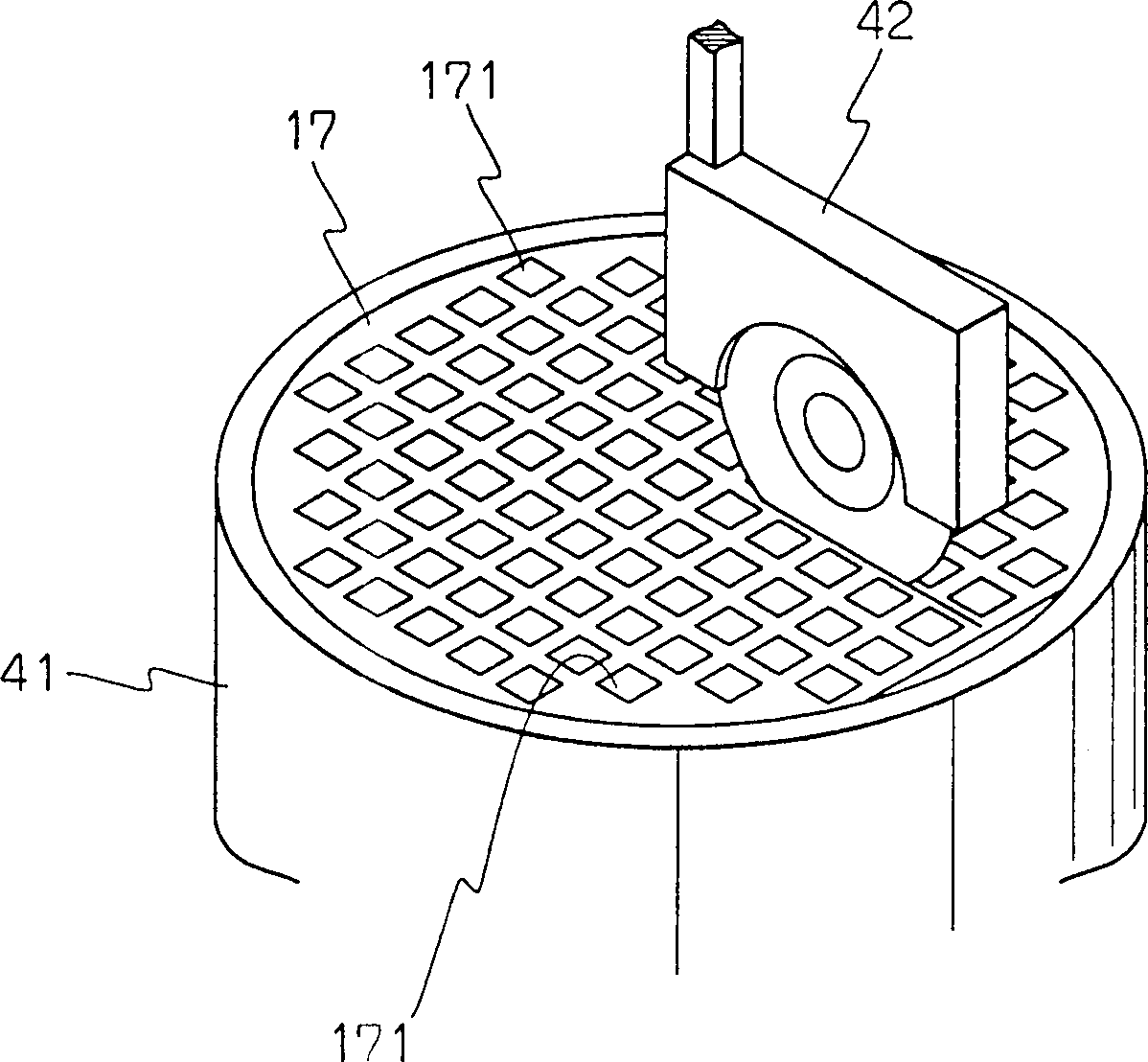

[0038] In the wafer manufacturing process 1, a 0.2-0.3mm thick oxide film (SiO 2 ) covering a flat silicon wafer 17 ( figure 2 ) on the upper surface; and the circuit patterns of the active circuits thereon are exposed and developed. The oxide layer is then etched into the circuit pattern. Thereafter, an infinite number of active circuits 171 are formed on the surface by doping the exposed surface of the wafer 17 (see image 3 ).

[0039] In the backside polishing process 2, the surface (backside) of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap