Intelligent temperature control interlocking ammonium chloride interception and cleaning integrated device

A technology of intelligent temperature control and ammonium chloride, applied in lighting and heating equipment, etc., can solve the problems of heat storage and release effect of heat storage carrier, loss of heat storage carrier due to personnel consumption, damage of artificial and heat storage carrier, etc., to achieve interception Excellent efficiency and effect, safe and convenient cleaning and replacement, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

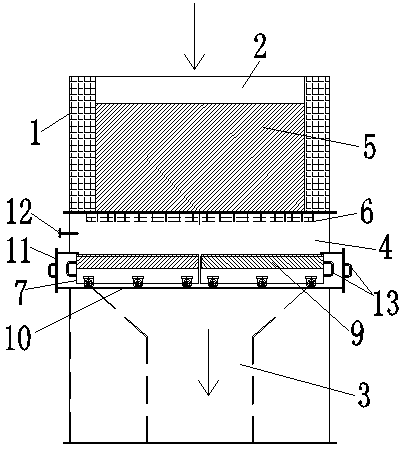

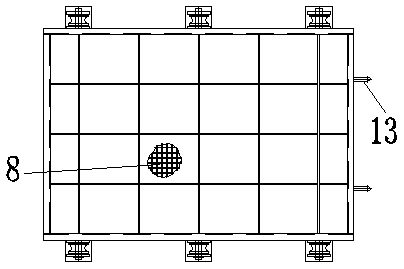

[0017] Such as figure 1 and figure 2 As shown, the intelligent temperature-controlled interlocking ammonium chloride interception and cleaning integrated device of the present invention includes a housing 1, an air inlet 2 is provided on the top of the housing 1, the longitudinal section is rectangular, and an outlet is provided at the bottom. The gas port 3 has a Y-shaped longitudinal section, a heat storage body structure is provided on the upper part of the housing 1, an interceptor structure is provided below the heat storage body structure, and a high temperature zone 4 above 350°C is located between them, The heat storage body structure includes a heat storage carrier 5 and a high temperature steel support frame 6, the high temperature steel support frame 6 is connected to the shell 1, the heat storage carrier 5 is arranged on the high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com