Sulfur deposition experimental device of sulfur-containing natural gas pipeline

A technology for natural gas pipelines and experimental devices, which is applied to the field of sulfur deposition experimental devices for sulfur-containing natural gas pipelines, can solve problems such as threatening the safety of pipeline transportation systems, threatening the safety of material structures, and increasing energy consumption, and achieves the effect of flexible experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

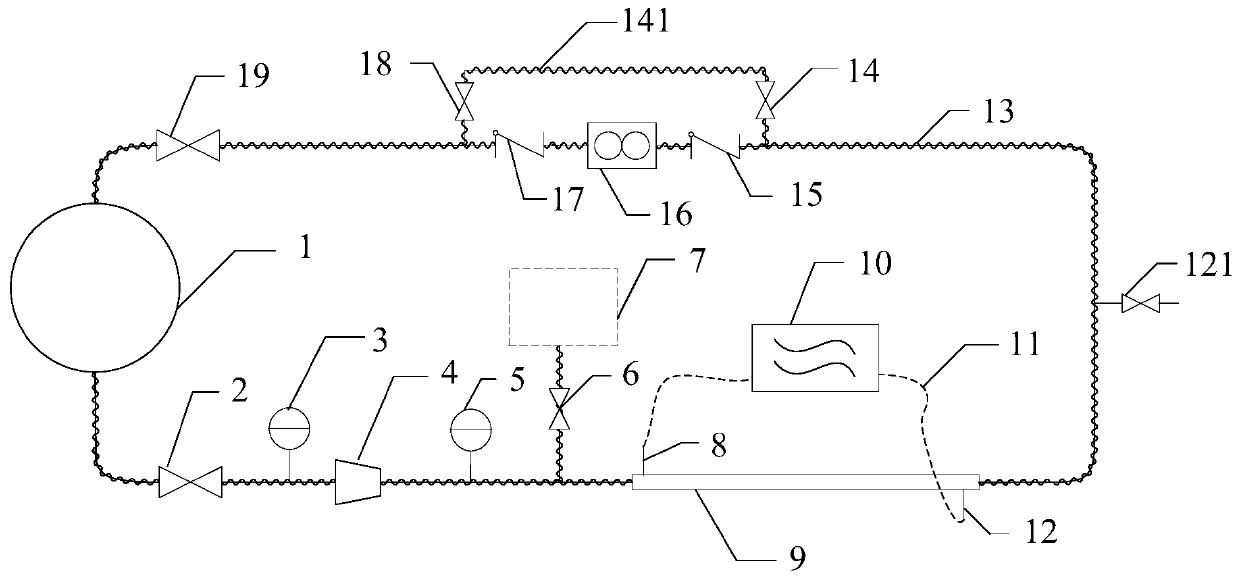

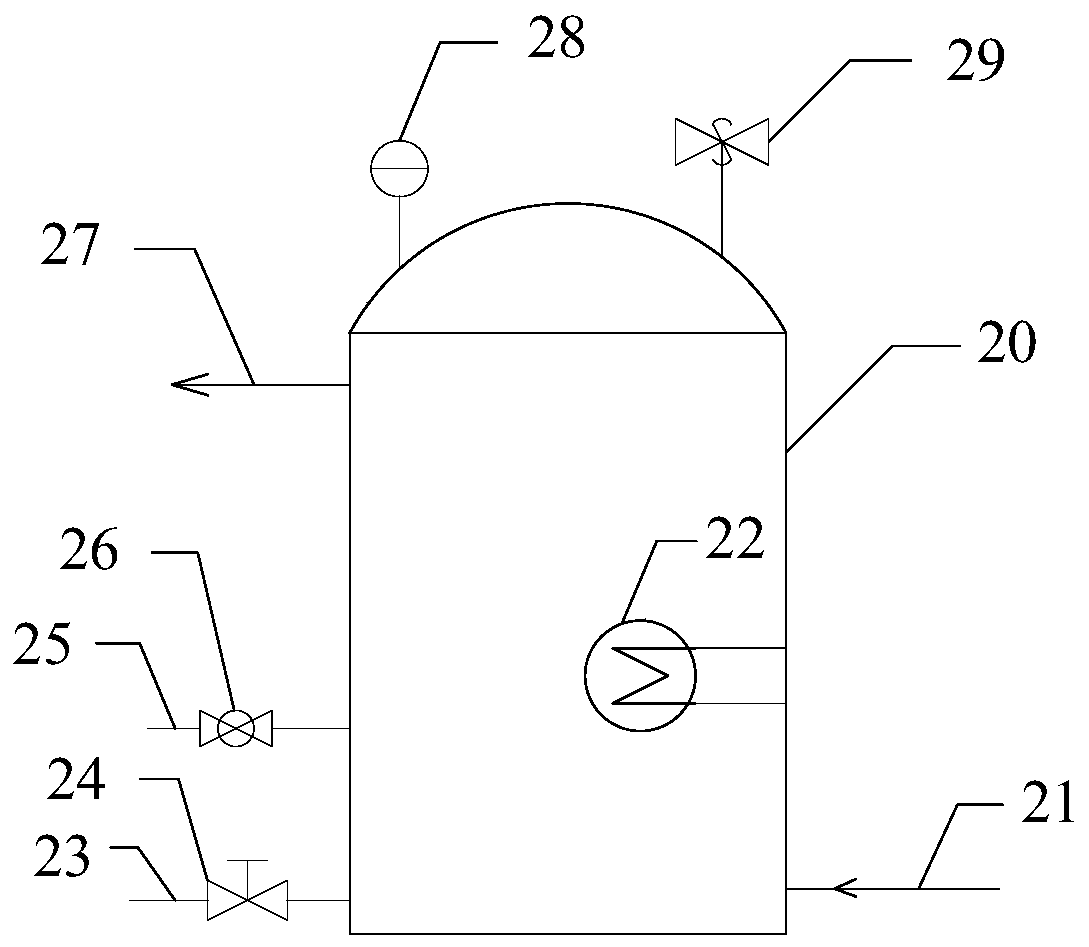

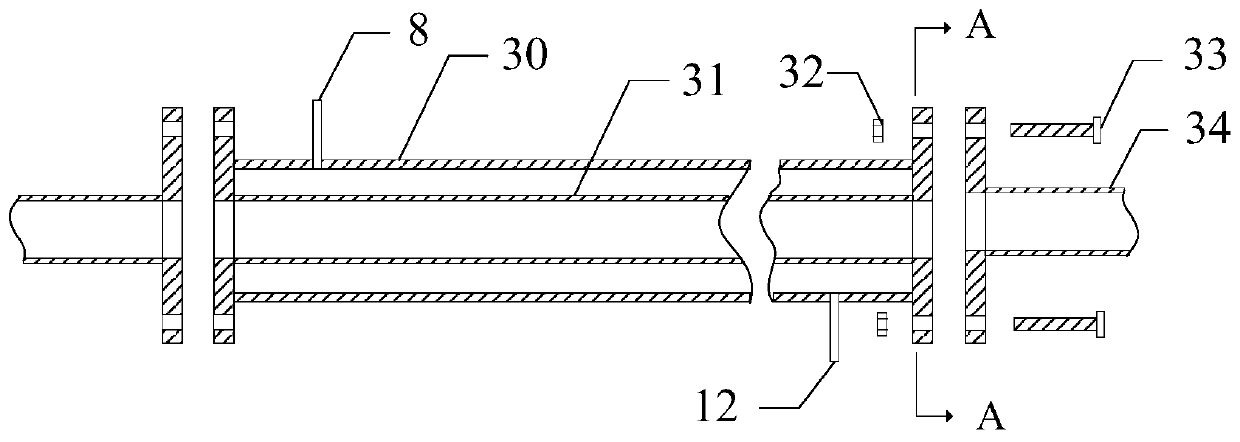

[0022] As shown in the figure, a sulfur-containing natural gas pipeline sulfur deposition experiment device includes a gas storage system, a loop system and a sulfur dissolving agent filling system. The gas storage system is a high-pressure gas tank 1, and the loop system includes a loop The high-pressure gas tank and the detachable pipe section 9 are connected on the loop pipeline, and the first control valve 2, the first pressure gauge 3, the compressor 4, the first control valve 2, the first pressure gauge 3, and the second Two pressure gauges 5 and sulfur dissolving agent filling system 7, a second control valve 6 is arranged between the sulfur dissolving agent filling system 7 and the loop pipeline; the two ends of the detachable pipe section are respectively provided with temperature control water bath inlets 8 and the temperature control water bath outlet 12, the temperature control water bath inlet 8 and the temperature control water bath outlet 12 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com