Indirect prediction method for remaining life of power battery

A power battery and prediction method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of difficult extraction of battery degradation characteristics, achieve the effect of low pressure on computing resources, improve accuracy, and solve the problem of fluctuations in curves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in more detail below in conjunction with specific embodiments.

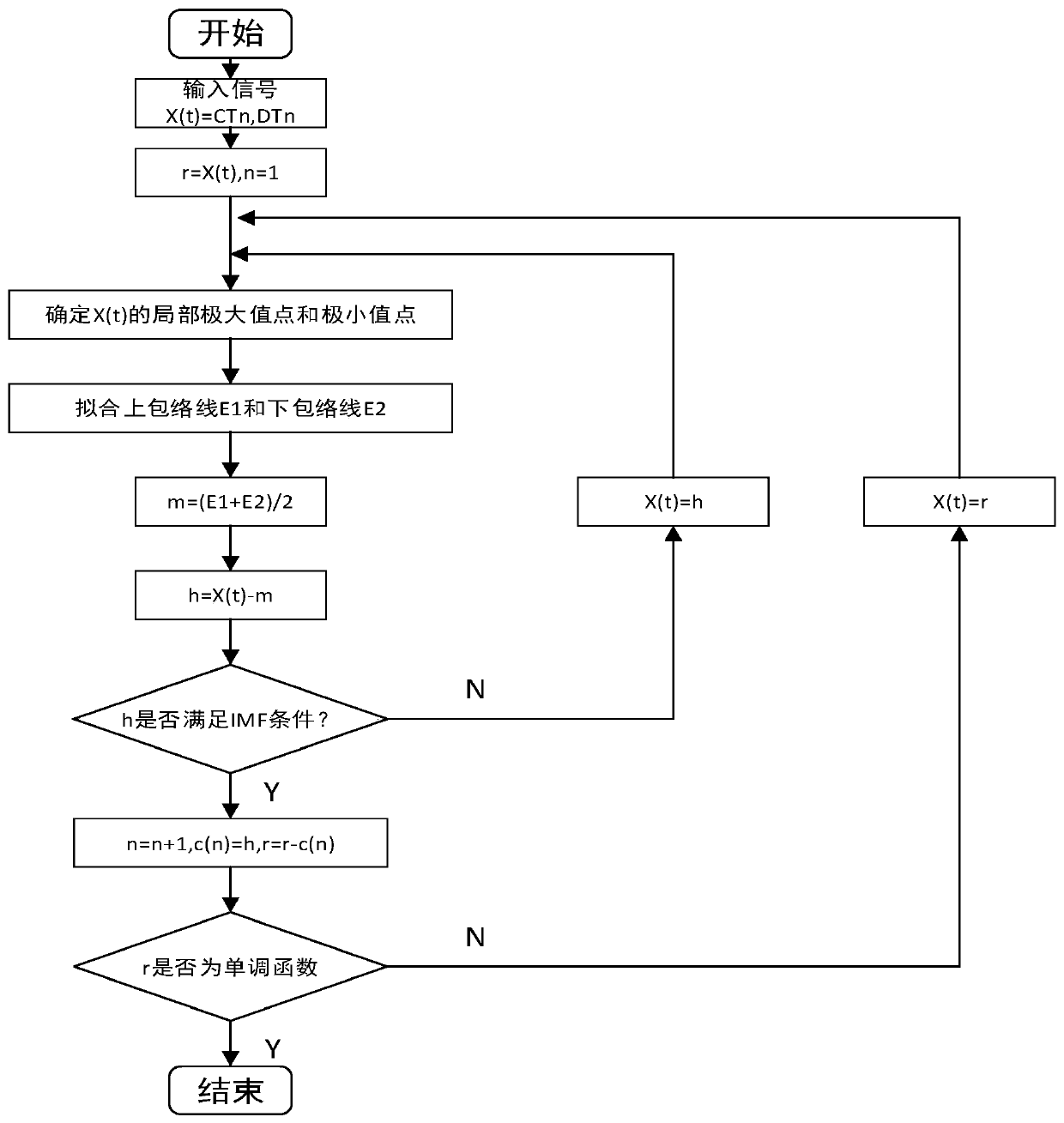

[0035] The present invention provides an indirect prediction method for the remaining life of a power battery, the realization process is as follows:

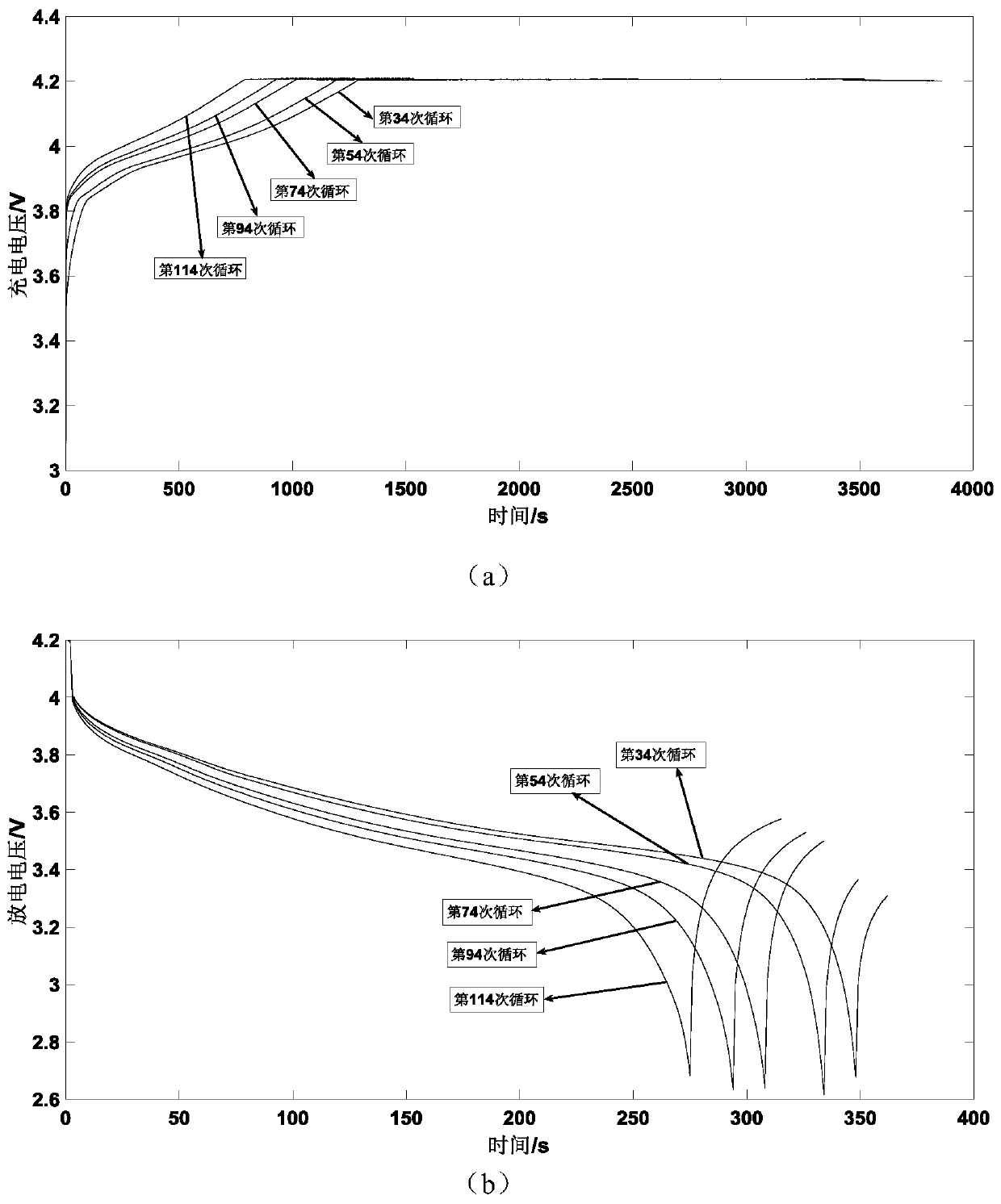

[0036] The battery data used in this example comes from the battery life test data numbered 5#, 6#, and 7# from the NASA Ames Center for Excellence Prediction. Battery specific parameters: 18650 battery, rated capacity 2000mAh, upper cut-off voltage 4.2V, lower cut-off voltage 2.75V.

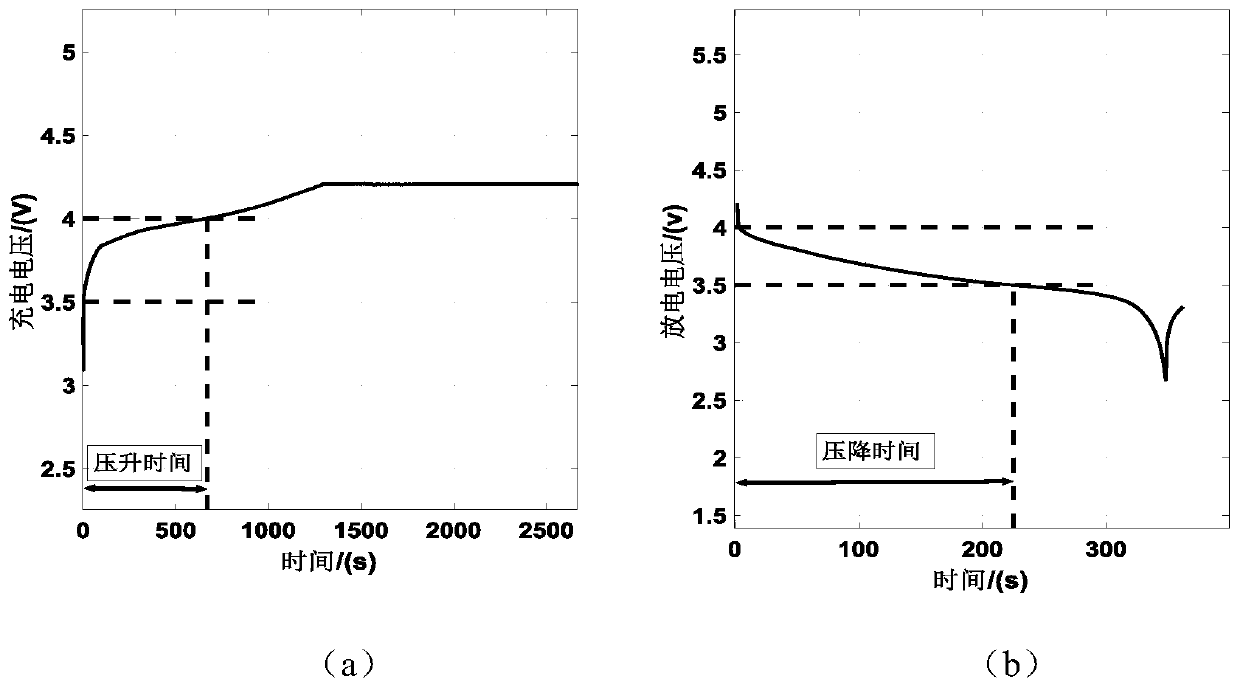

[0037] Step 1: Perform a charge-discharge cycle life test on the power battery, and record the voltage change with time during each charge and discharge process, until the maximum discharge capacity of the power battery drops to 70% of the rated capacity, stop the experiment.

[0038] The specific steps of the battery cycle life test are:

[0039] ①Constant current charging: all three batteries are charged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com