Method, device and storage medium for evaluating peripheral edge wear of cylindrical vertical milling cutter

An evaluation method, vertical milling technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as the height VB of the wear zone on the knife face and its area, and principle errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

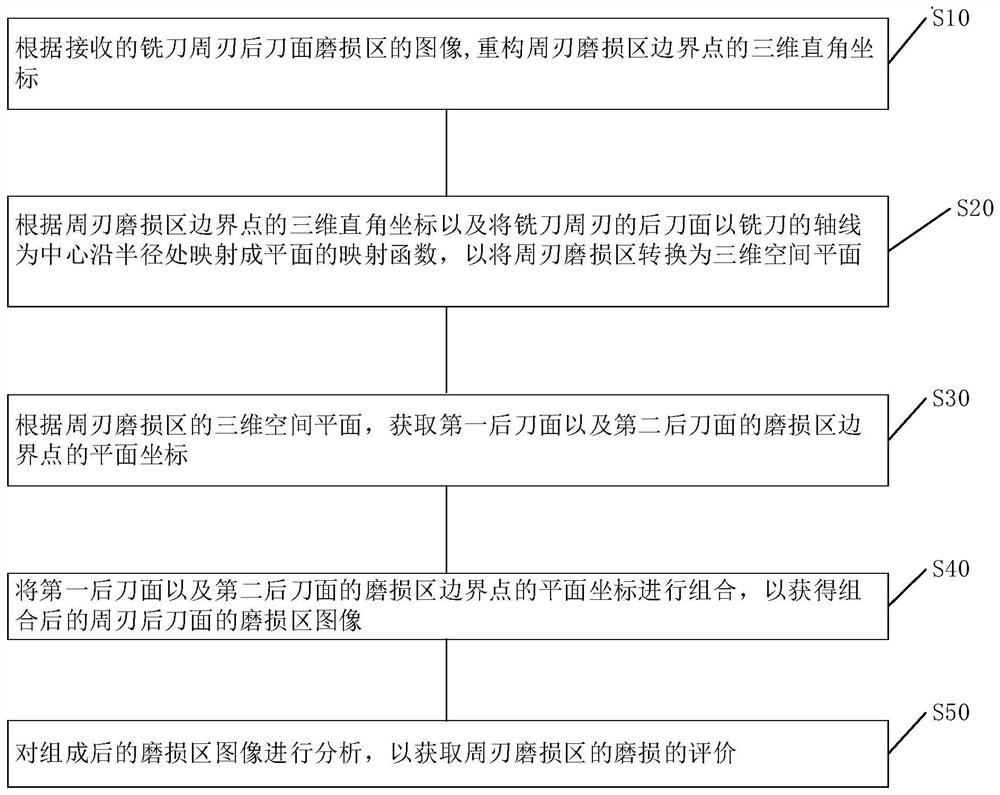

[0066] see Figure 1 to Figure 14 , the embodiment of the present invention provides a method for evaluating the peripheral edge wear of a cylindrical vertical milling cutter, including:

[0067] S10, reconstructing the three-dimensional Cartesian coordinates of boundary points of the flank wear area of the milling cutter according to the received image of the flank wear area of the milling cutter.

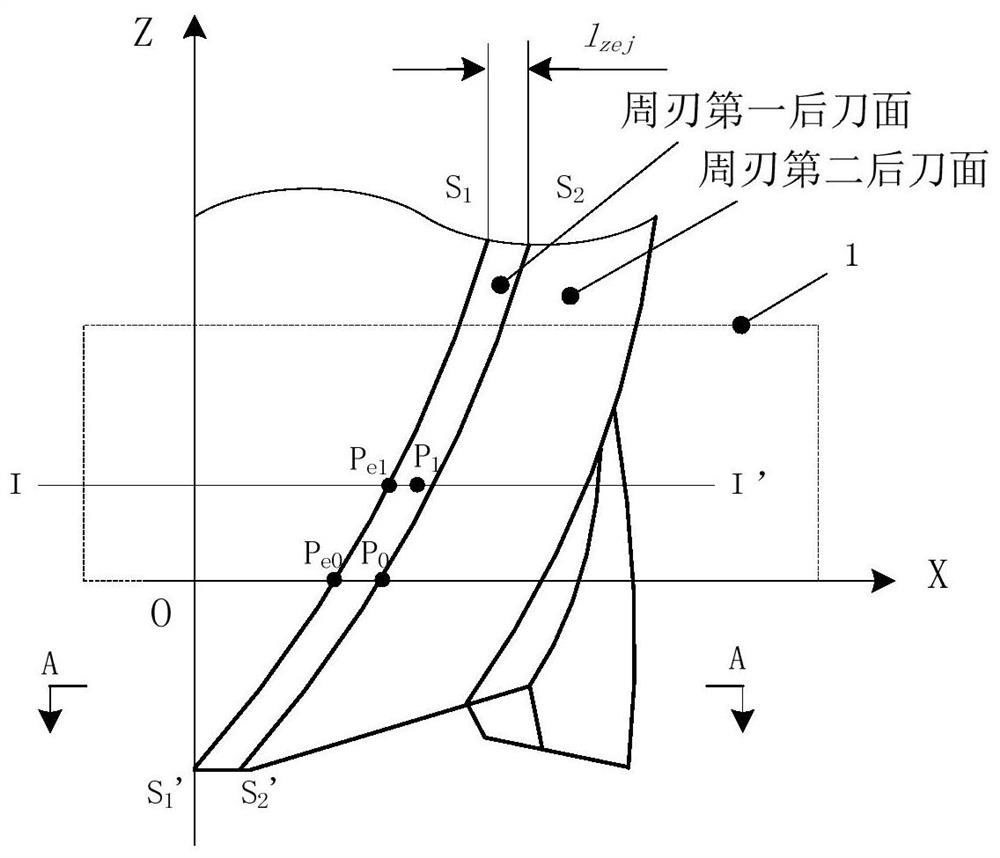

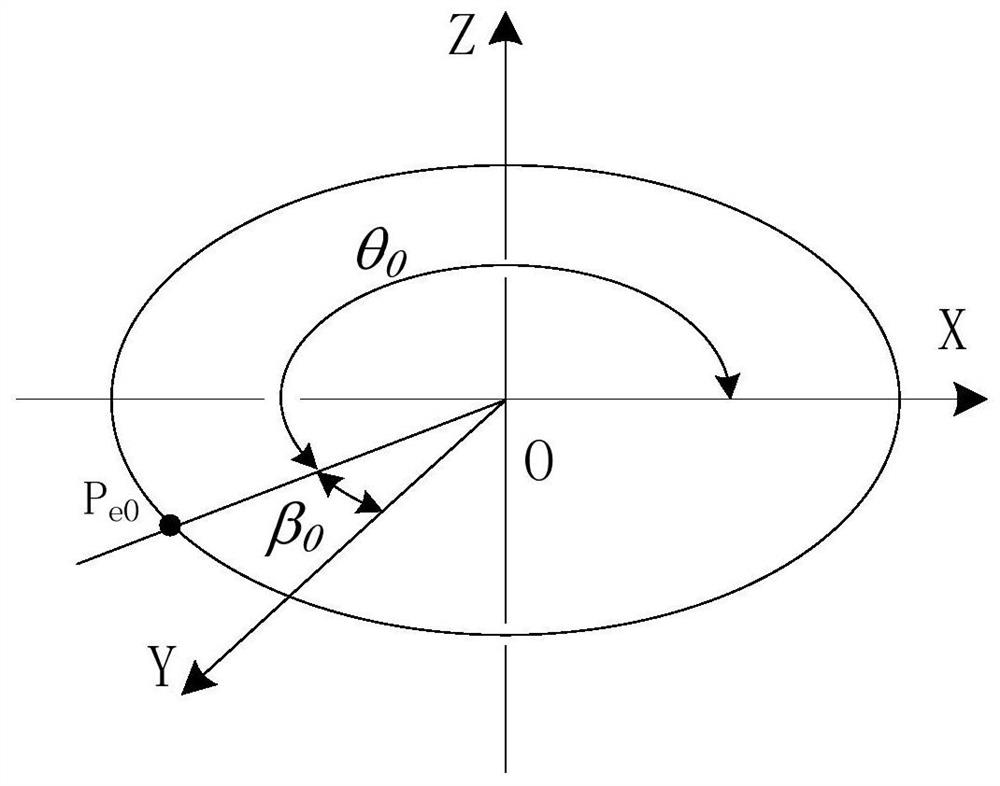

[0068] In the present embodiment, according to the images received by the video microscope, a rectangular area 1 is constructed with sides perpendicular to the axis of the milling cutter and covering the wear zone (see figure 2 ). First, take the tool axis as the Z axis, and the rectangular side (near the bottom edge) as the X axis to establish a rectangular coordinate system, and the X axis and the helical line S at the top of the peripheral cutting edge 1 S 1 ', helix line S at the bottom of the peripheral edge 2 S 2 'respectively handed over to P e0 and P 0 Point, w...

no. 2 example

[0111] The second embodiment of the present invention provides a peripheral edge wear evaluation device for a cylindrical vertical milling cutter, including:

[0112] The three-dimensional Cartesian coordinate reconstruction unit 100 is used to reconstruct the three-dimensional Cartesian coordinates of the boundary points of the peripheral edge wear zone according to the received image of the flank wear zone of the peripheral edge of the milling cutter;

[0113] The three-dimensional space plane reconstruction unit 200 is used to map the flank of the peripheral edge of the milling cutter into a plane along the radius with the axis of the milling cutter as the center according to the three-dimensional Cartesian coordinates of the boundary points of the wear zone of the peripheral edge The mapping function, to convert the wear area of the peripheral edge into a three-dimensional space plane;

[0114] The acquisition unit 300 is configured to acquire the plane coordinates of th...

no. 4 example

[0134] The present invention provides a peripheral edge wear evaluation device of a cylindrical vertical milling cutter, comprising a processor, a memory, and a computer program stored in the memory and configured to be executed by the processing, when the processor executes the computer program Realize the method for evaluating the peripheral edge wear of a cylindrical vertical milling cutter as described in any one of the above-mentioned embodiments.

[0135] Exemplarily, the computer program described in the fourth embodiment of the present invention can be divided into one or more modules, and the one or more modules are stored in the memory and executed by the processor to Complete the present invention. The one or more modules may be a series of computer program instruction segments capable of accomplishing specific functions, and the instruction segments are used to describe the execution process of the computer program in the implementation server device. For example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com