Non-contact multi-scale crack identification method

A non-contact, recognition method technology, applied in the field of image recognition engineering, can solve the problem of time-consuming and labor-consuming cracks, and achieve the effect of scientific and reasonable calculation method, easy extraction, and good threshold processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

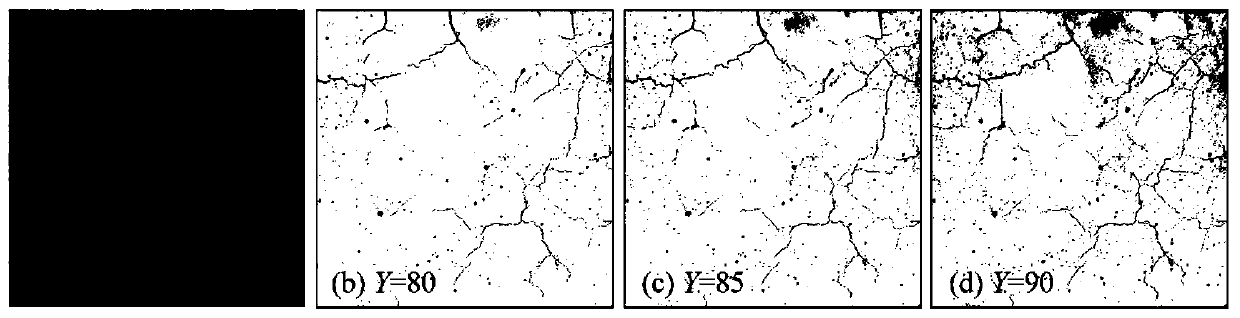

[0071] The invention provides a non-contact crack recognition technology based on image analysis, which can realize automatic collection, analysis and identification of cracks in component surface photos, and finally output simple crack photos and crack length, width, path, etc. Geometry information, so as to achieve the purpose of real-time monitoring and real-time analysis of component or component surface cracks. The present invention is mainly composed of an image acquisition system and a computer system in terms of system configuration. The image acquisition system is used to complete the automatic acquisition of images, obtain the basic image data information of crack analysis, and then identify and analyze the cracks in the image by the computer system, output crack information, and provide early warning for crack detection.

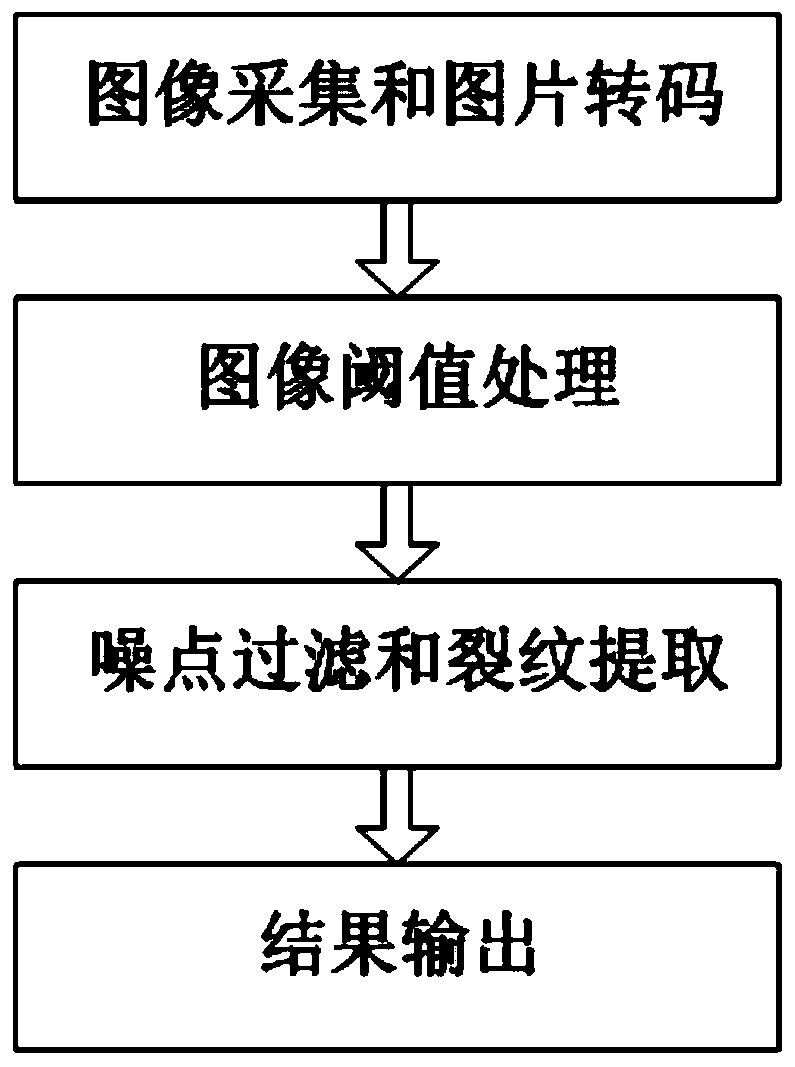

[0072] like figure 1 As shown, the specific process of the present invention mainly includes: 1. image acquisition and image transcoding; 2. ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com