Method and apparatus for washing plastics materials

A technology for cleaning plastic materials and containers, applied in cleaning methods and utensils, cleaning methods using liquids, plastic recycling, etc., can solve problems such as reducing the efficiency of the separation process, and achieve the effect of simplifying the system, reducing economic advantages, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

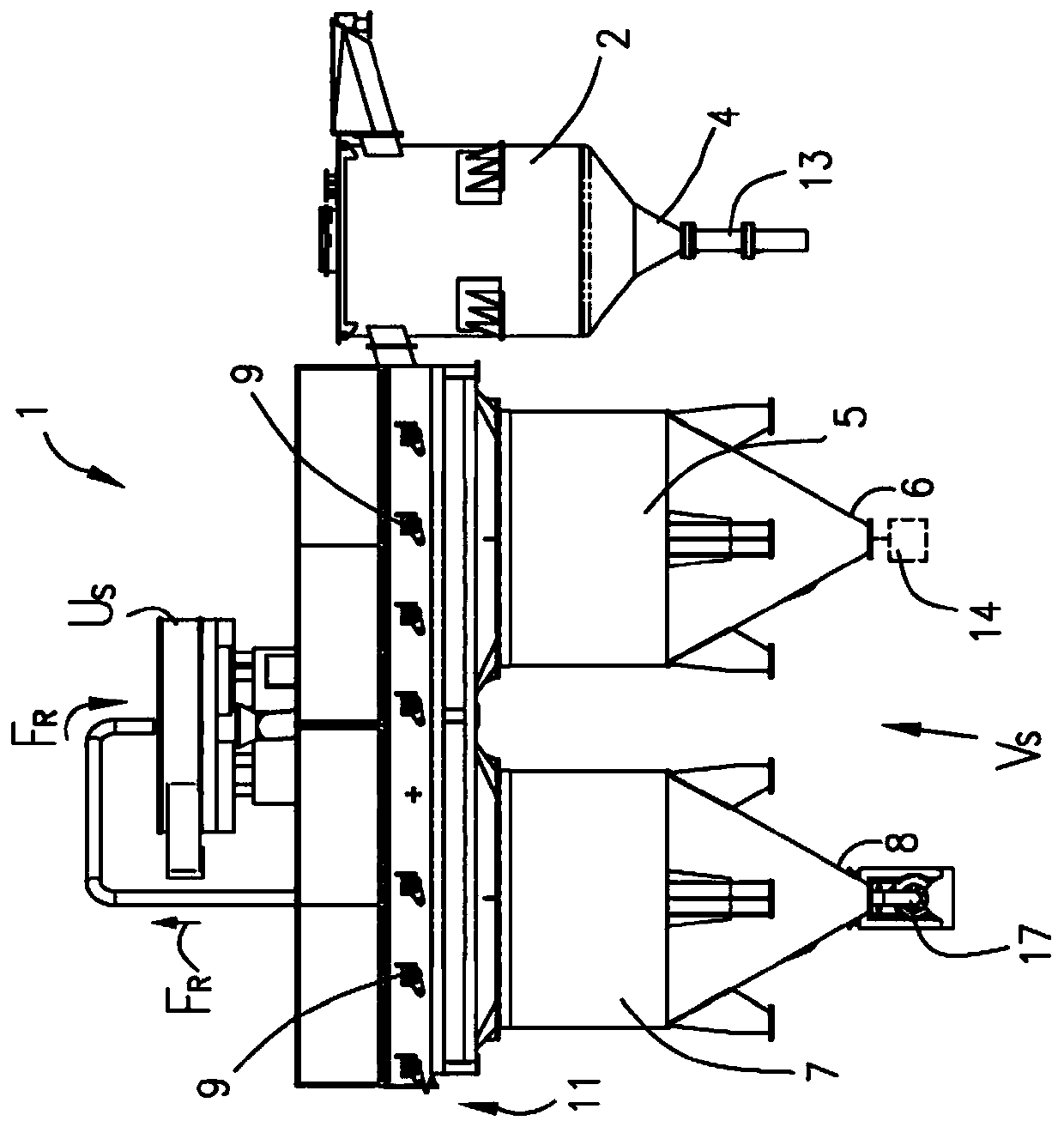

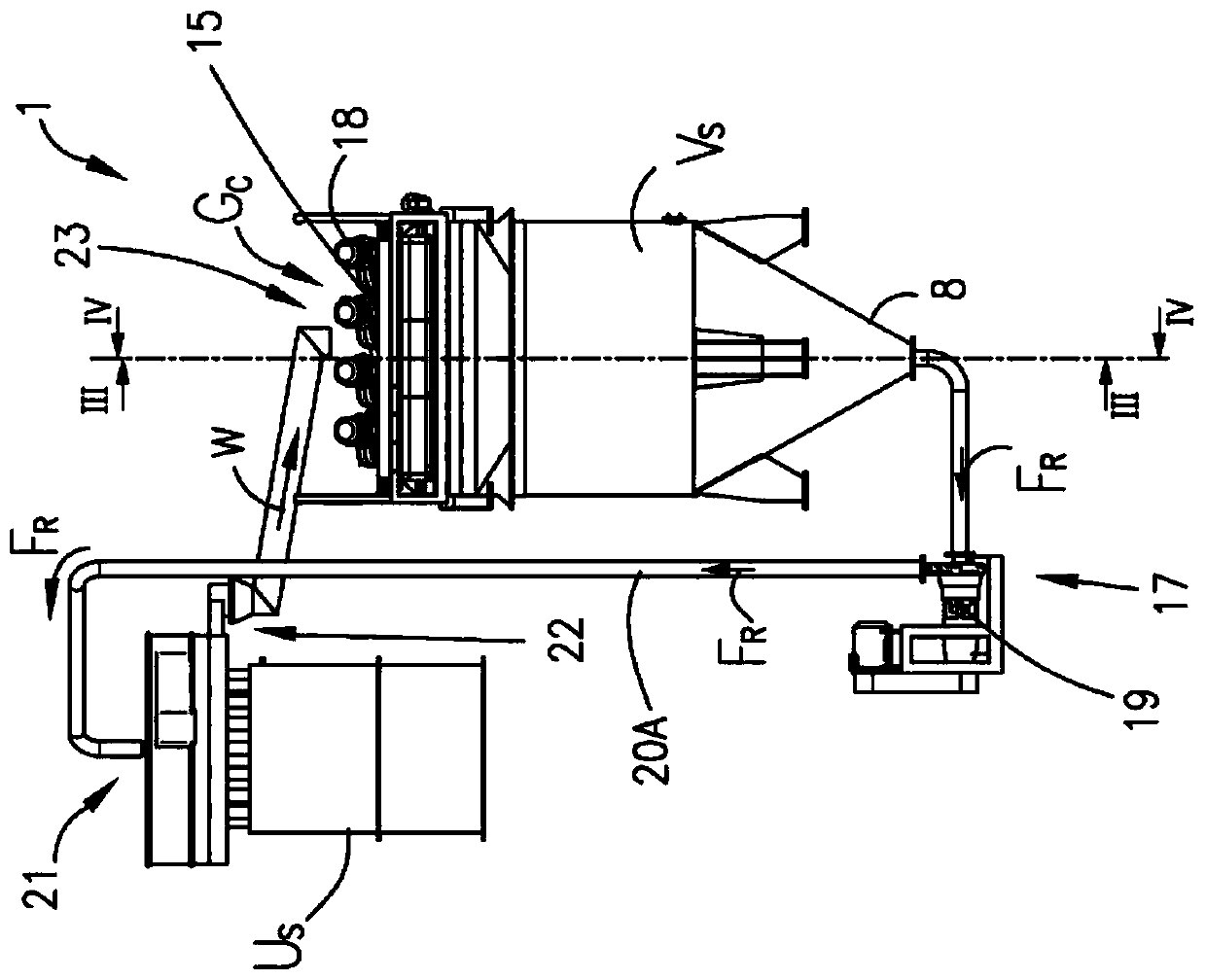

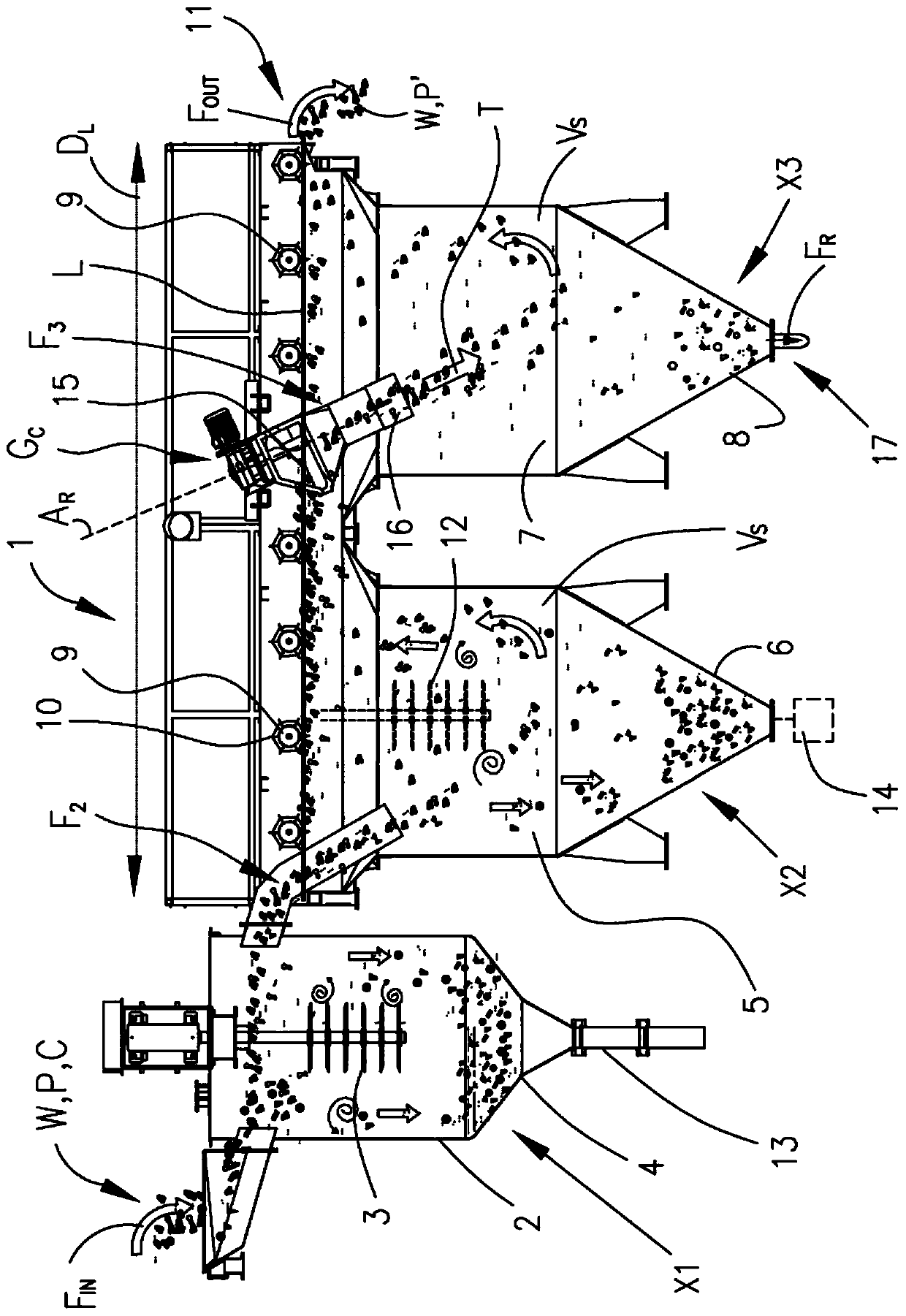

[0033] With reference to the accompanying drawings, an apparatus 1 for cleaning plastic material P and separating polluting substances C therefrom is disclosed below.

[0034] The device 1 comprises a cleaning container 2 provided with agitator means 3 and adapted to receive a first flow F of cleaning fluid W IN and plastic material P including contaminants C for a first separation action.

[0035] The stirrer means 3 are configured to generate a turbulent stirring action to detach from the plastic material P by mechanical action the parts of the contaminating material C attached thereto.

[0036] The cleaning container 2 is delimited below by a first bottom 4 adapted to receive a first portion X1 of heavier contaminants C. As shown in FIG.

[0037] The cleaning container 2 is provided below with a removal device 13 of valve or pump type for periodically removing the first portion X1 of the contaminants C deposited on the first bottom 4 .

[0038] The plant 1 comprises a sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com