Casting die machining equipment

A technology for processing equipment and casting molds, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as harsh working environment, low linkage, and difficulty in replacing abrasive belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

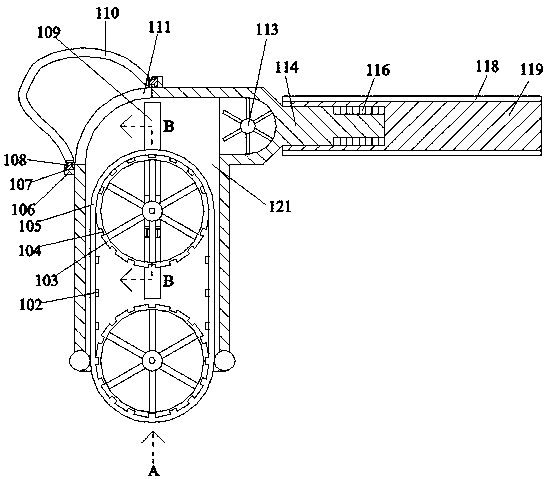

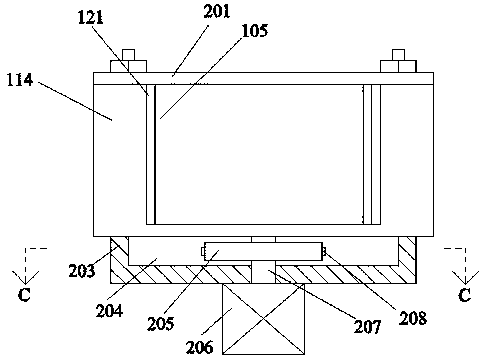

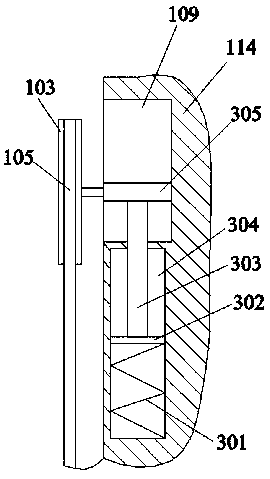

[0021] like Figure 1-Figure 4 As shown in the figure, the present invention will be described in detail. For the convenience of description, the orientations mentioned below are now defined as follows: figure 1 The projection relationship itself has the same direction of up, down, left, right, front, and back. A casting mold processing equipment of the present invention includes a transmission box 114. The right side of the outer surface of the transmission box 114 is provided with a handle device for convenient use by personnel. The transmission box 114 is provided with an accommodating cavity 121 with an opening facing downward, the left end wall of the accommodating cavity 121 communicates with a penetration cavity 111 with an opening, and a cloth bag device for receiving dust is provided at the outer position of the penetration cavity 111 , the accommodating cavity 121 is provided with a polishing device for grinding and is convenient for blowing the dust out to the cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com