Floor common formwork removing pre-buried part assembly and manufacturing and mounting construction methods thereof

A technology of embedded parts and formwork, which is applied in the field preparation of building components, processing of formwork, construction, etc., can solve the problems of slow formwork removal, slow work efficiency, and large safety hazards, and achieve high applicability, The effect of fast and easy demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A common formwork demoulding embedded part assembly for "ten" joints Ⅰ:

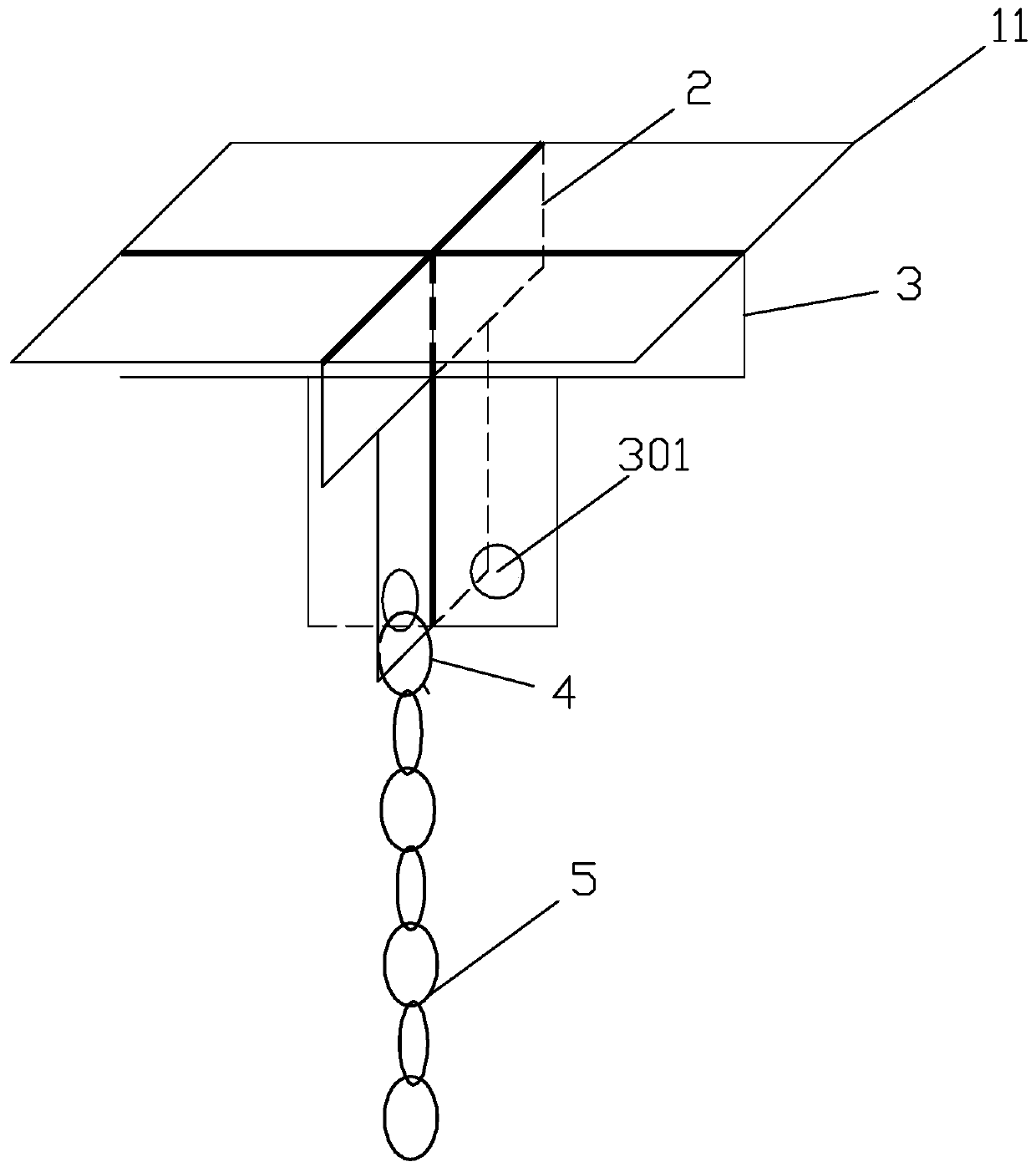

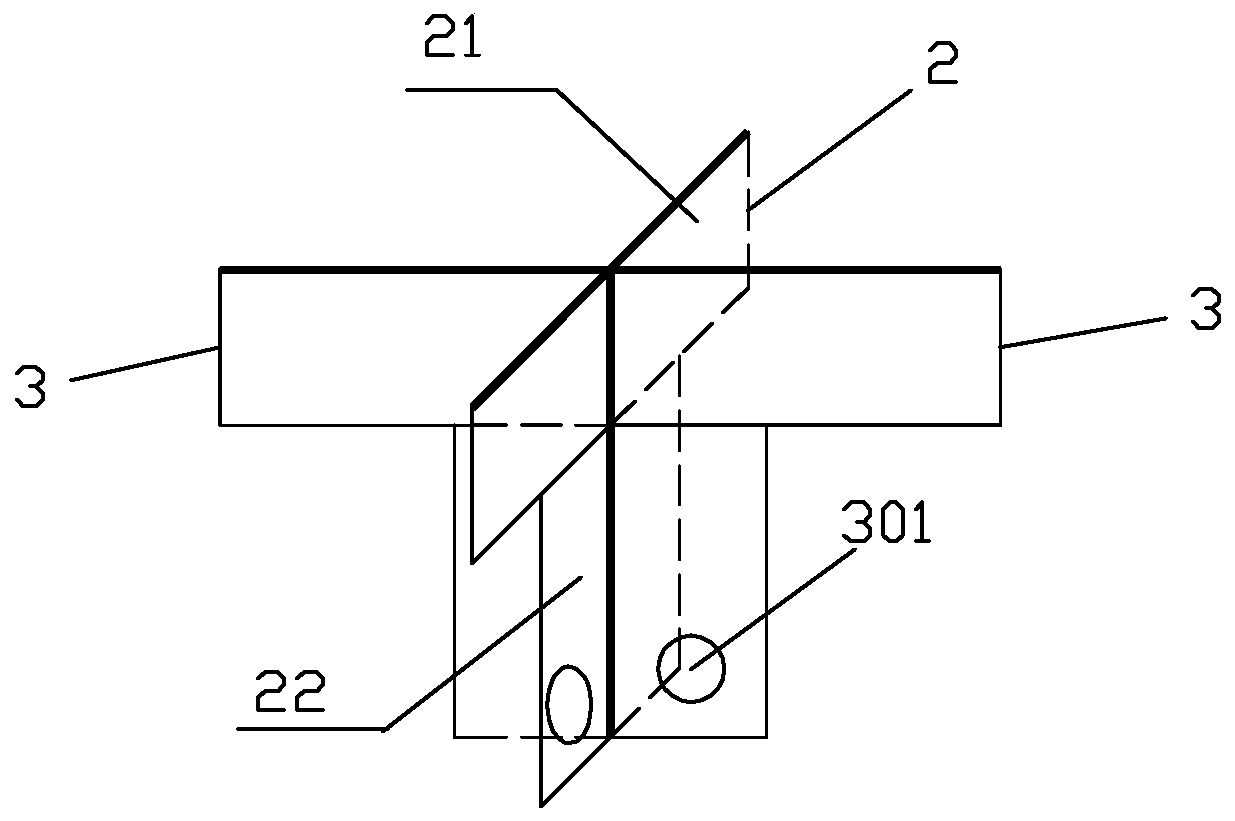

[0078] Such as figure 1 As shown, the general formwork demoulding embedded part assembly I for the "ten" joint of the floor includes a square top cover plate I11, a curb plate I2, a curb plate II3, a connecting movable buckle 4 and a retractable zipper 5;

[0079] The embedded part assembly I of the ordinary formwork demolition embedded part assembly I for the "ten" joint is composed of the top cover plate I11 with the top cover plate 1 as a square and the slab I2 and the two sides of the slab I2. The slab II3 is fixedly connected to form the embedded parts of the cross-shaped floor common formwork demoulding embedded parts assembly;

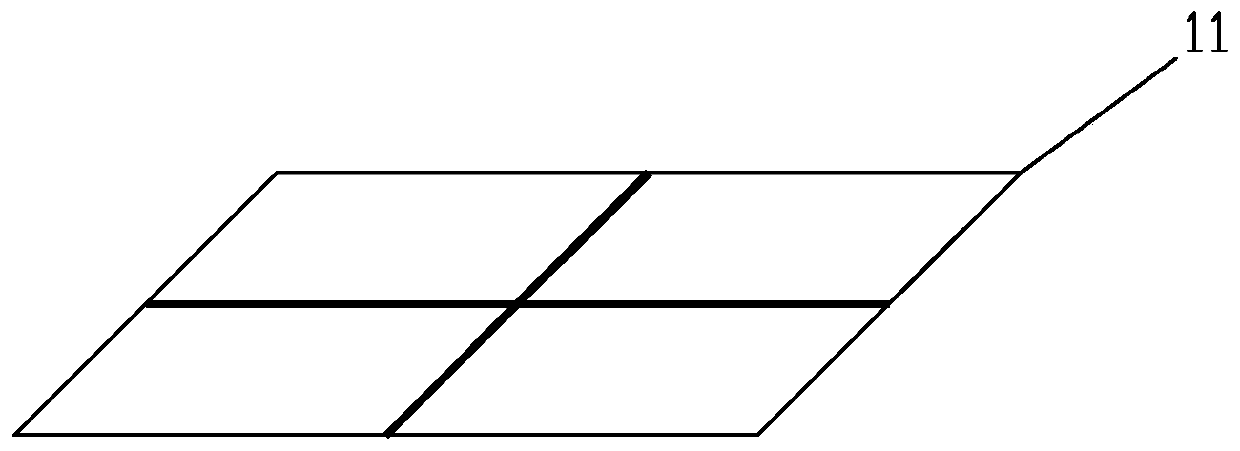

[0080] The square top cover plate I11 is a square plate surrounded by a hypotenuse with a width of 3-10mm, the slope of the hypotenuse α, that is, the angle between the hypotenuse of the top cover plate and the horizontal plane is 30°-60° (see diagram 2-1 , Fig...

Embodiment 2

[0085] A common formwork demoulding embedded part assembly for T-joint II:

[0086] Such as image 3 As shown, the general formwork demoulding embedded part assembly II for the T-shaped joint includes a rectangular top cover plate II12, a stretching plate I2, a stretching plate II3, a connecting movable buckle 4 and a retractable zipper 5;

[0087] There is a hypotenuse with a width of about 3 to 10 mm around the rectangular top cover plate II12, and the slope α of the hypotenuse, that is, the angle between the hypotenuse of the top cover plate and the horizontal plane is 30° to 60°, (see Pic 4-1 and Figure 12 ,which is Figure 10 C-C cross-sectional view);

[0088] The embedded part component II of the ordinary formwork demoulding embedded part assembly II for the T-shaped joint is fixedly connected with the rectangular top cover plate II12, the drawn plate I2 and the drawn plate II3 located on one side of the drawn plate I2, forming The skeleton of the T-shaped embedde...

Embodiment 3

[0094] The invention discloses a method for manufacturing, installing and constructing a common formwork demoulding embedded part assembly of a floor slab.

[0095] It is a general formwork demoulding and embedded part assembly for "ten" joints described in the first embodiment and a common formwork demoulding and embedded part assembly for T-shaped joints described in the second embodiment. The method of installation and production;

[0096] It is made by connecting steel plate or aluminum formwork or iron plate or ABS hard material with a certain thickness (material with a thickness of about 1 to 3mm) and other materials that can achieve the strength required for demolition; according to the design drawing, it is connected by fixed connection. The embedded parts of a general formwork removal embedded part assembly of the floor slab are pre-embedded at the cross or right-angled side of the formwork after the splicing is completed; After the support system of the formwork is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com