Novel alloy formwork construction method for building field

A construction method and formwork technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as troublesome operation, slow formwork and formwork removal, affecting construction progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

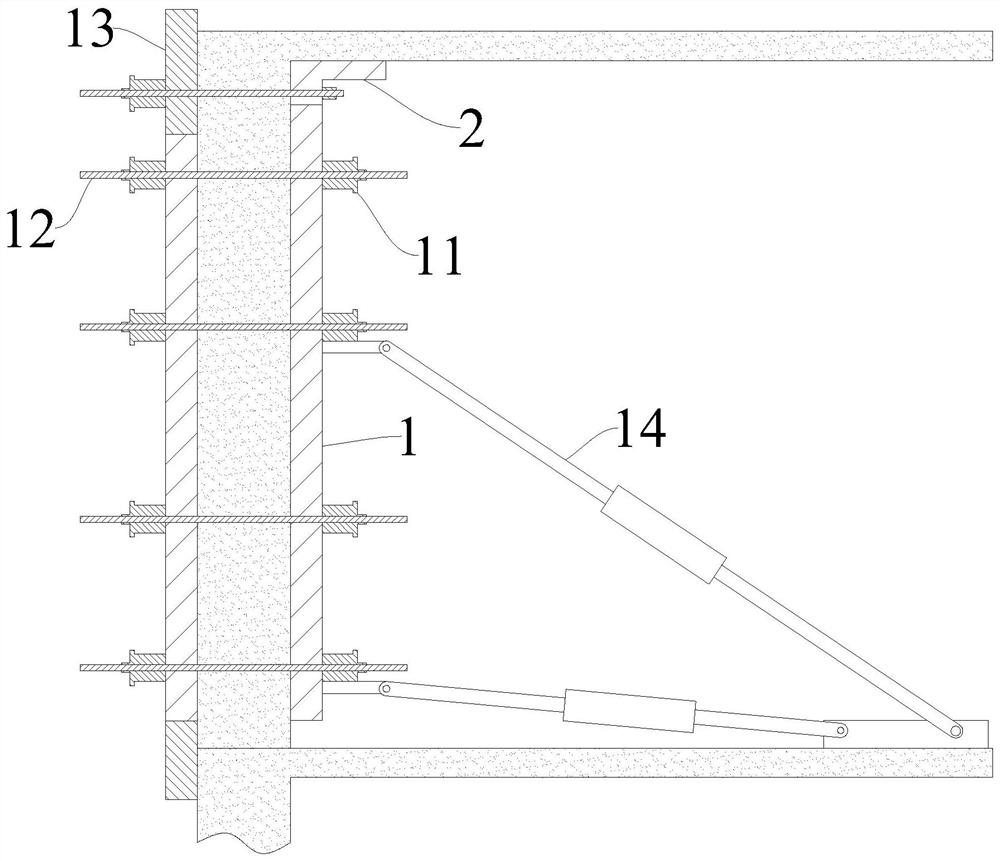

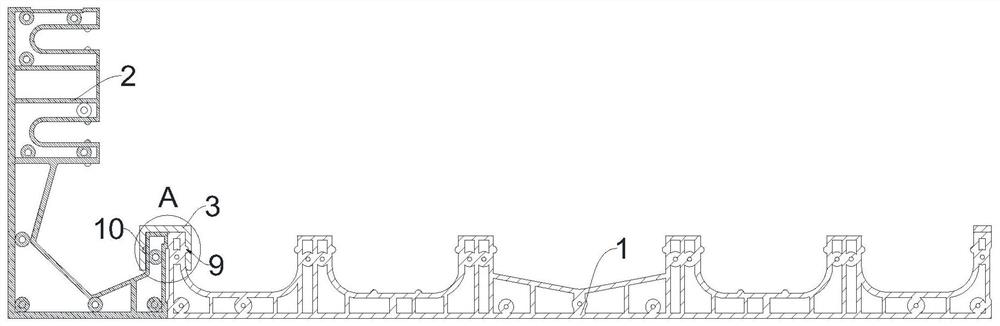

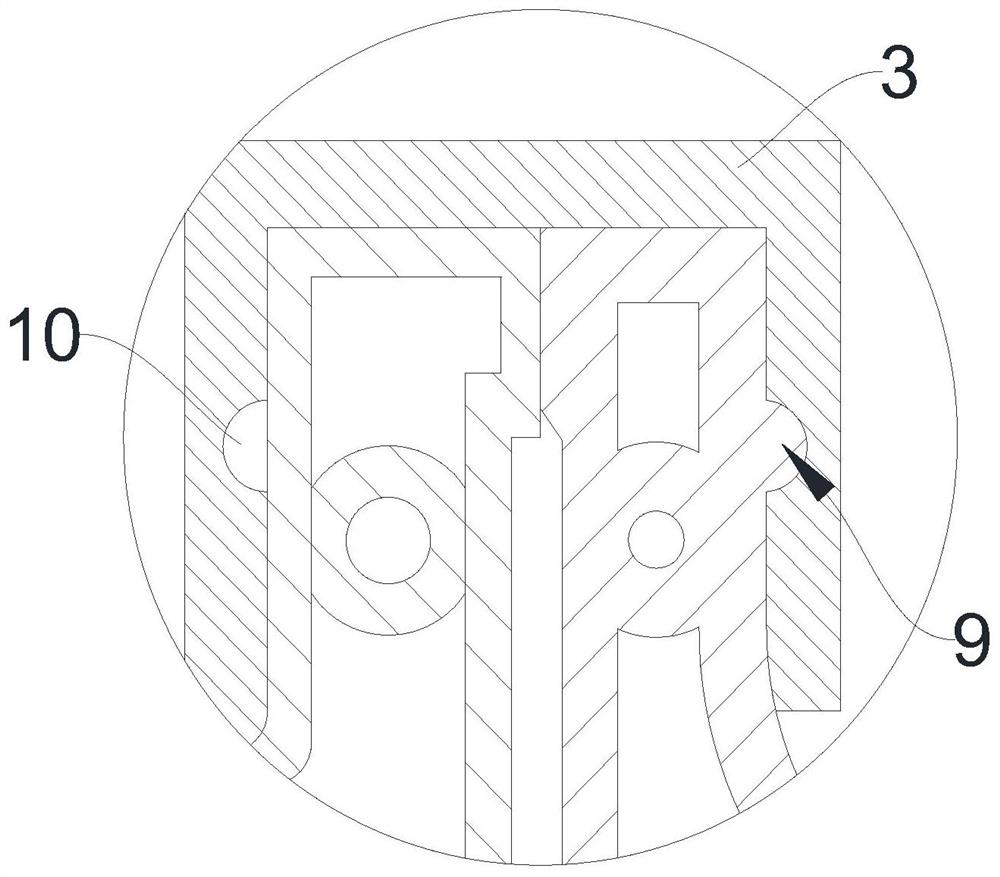

[0036] Please refer to Figure 1-Figure 5 , figure 1 Shown is a partial cross-sectional view of the alloy template provided by the embodiment of the present invention after construction and installation; figure 2 Shown is a cross-sectional view of the interior wall formwork 1 and the top plate corner C-shaped formwork 2 provided by the embodiment of the present invention after installation; image 3 shown as figure 2 Enlarged image at A; Figure 4 Shown is a cross-sectional view of a top plate corner C-shaped formwork 2 provided by an embodiment of the present invention; Figure 5 Shown is a cross-sectional view of an interior wall formwork 1 provided in an embodiment of the present invention.

[0037] This embodiment provides a new alloy formwork construction method for the construction field, which includes installing an inner wall formwork 1 and an outer wall formwork on both sides of the wall, and installing an outer wall receiving plate 13 for special connection on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com