Refinery flaw detection worker retention detection method

A technology for operators and detection methods, applied in the field of security management, can solve problems such as sub-regional judgment that is not suitable for complex business scenarios, and achieve the effect of realizing intelligence and optimizing security management methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

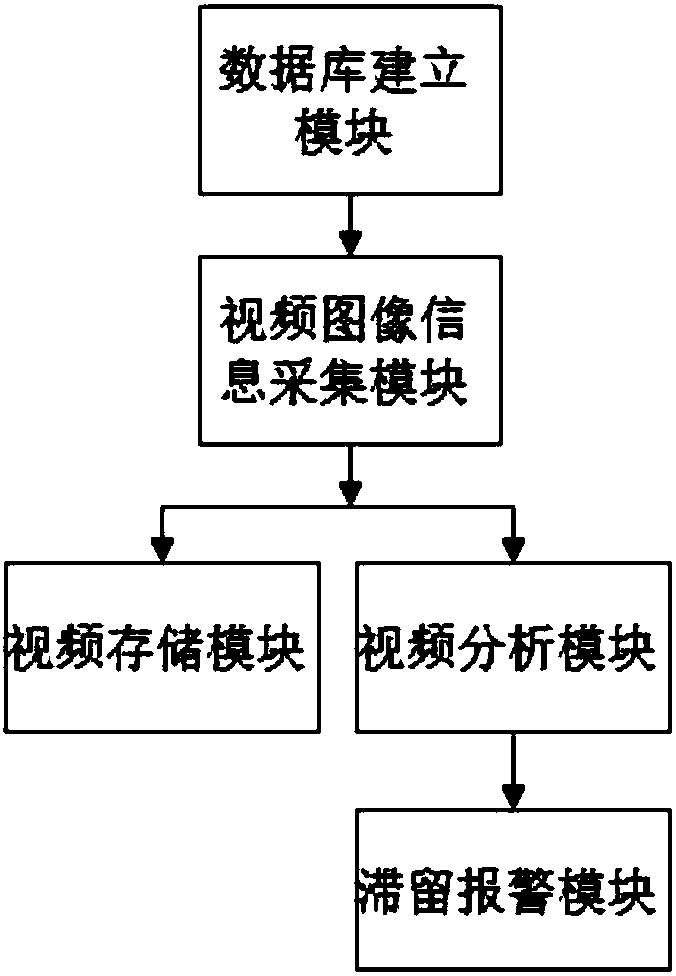

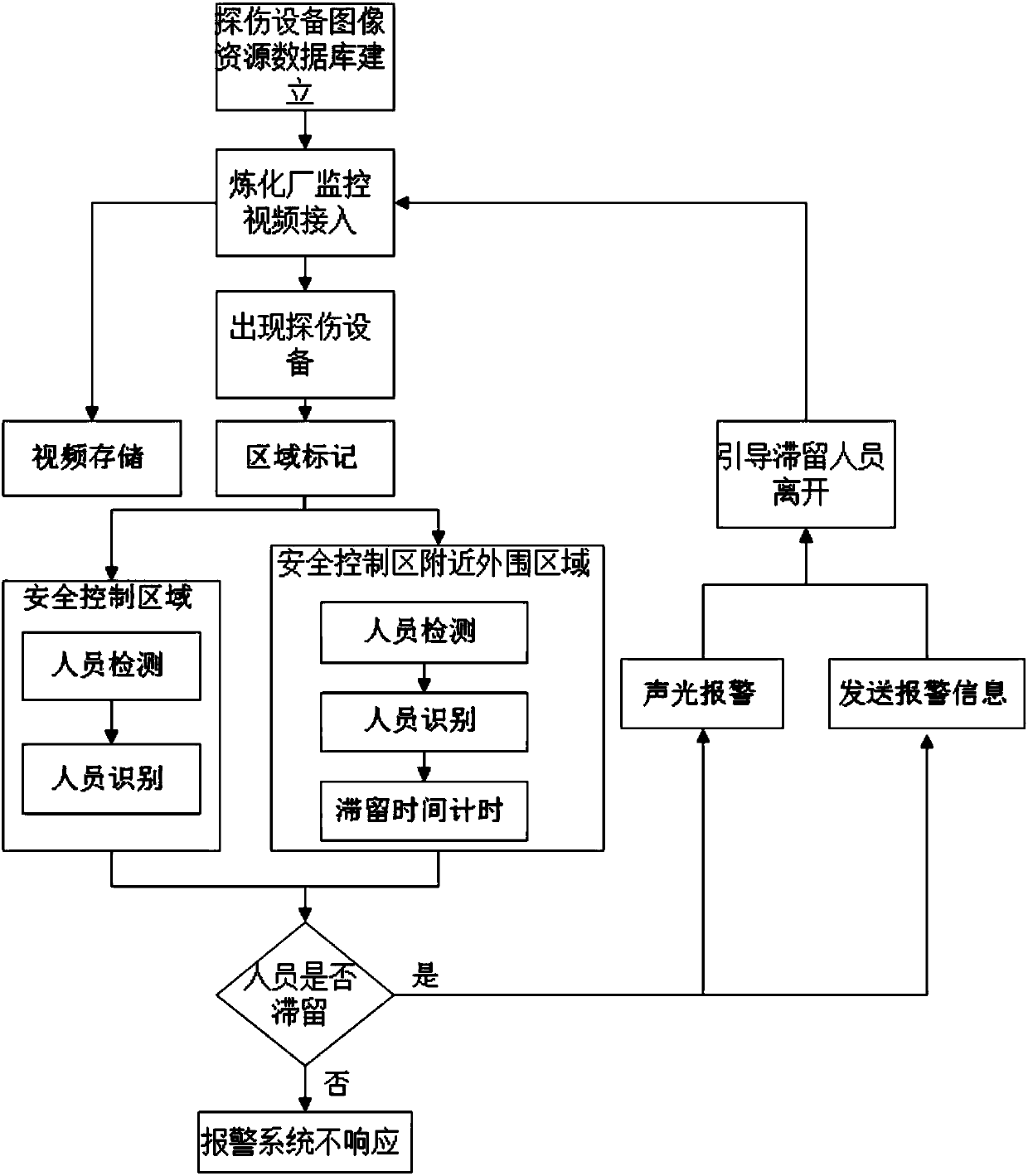

[0030] like figure 1 and figure 2 As shown, a method for detecting the detention of flaw detection workers in a refinery plant includes a database establishment module, a video image information acquisition module, a video storage module, a video analysis module and a detention alarm module, wherein:

[0031] The database establishment module establishes the image resource database of the flaw detection equipment;

[0032] The video image information collection module collects video images, and transmits the collected video images to the video storage module and the video analysis module respectively;

[0033] The video storage module transmits the video image to the video storage server for storage;

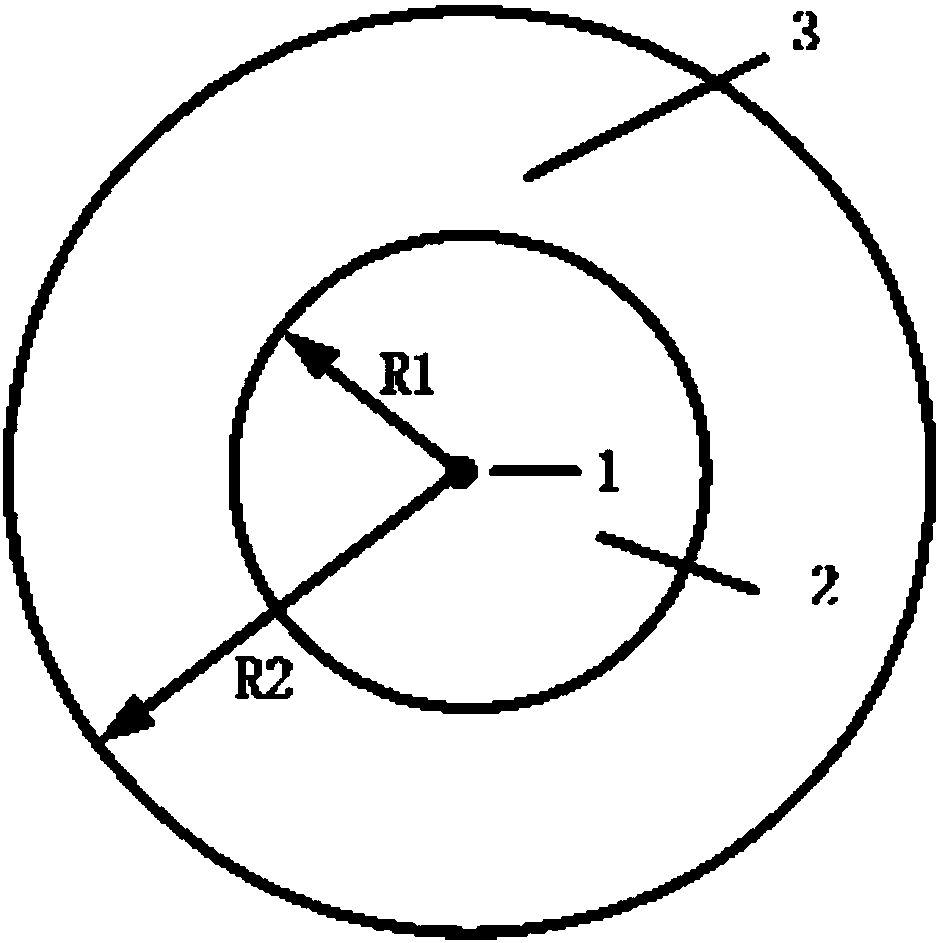

[0034] The video analysis module analyzes and processes the video image. Once the flaw detection equipment appears in the video image, it calculates the radius of the safety control area according to the health protection standard of radiographic inspection, and then marks th...

Embodiment 2

[0047] like figure 1 and figure 2 As shown, a method for detecting the detention of flaw detection workers in a refinery plant includes a database establishment module, a video image information acquisition module, a video storage module, a video analysis module and a detention alarm module, wherein:

[0048] The database establishment module establishes the image resource database of the flaw detection equipment;

[0049] The video image information collection module collects video images, and transmits the collected video images to the video storage module and the video analysis module respectively;

[0050]The video analysis module analyzes and processes the video images, calculates the radius of the safety control area according to the radiographic inspection and health protection standards, and then marks the surrounding peripheral areas to automatically generate warning areas. The video analysis module analyzes the video images in the safety control area. Personnel de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com