Floating connector

A technology of floating connectors and auxiliary connections, which is applied in the field of honing processing, can solve problems such as poor tool rotation stability, achieve high processing accuracy, improve processing accuracy, and optimize processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

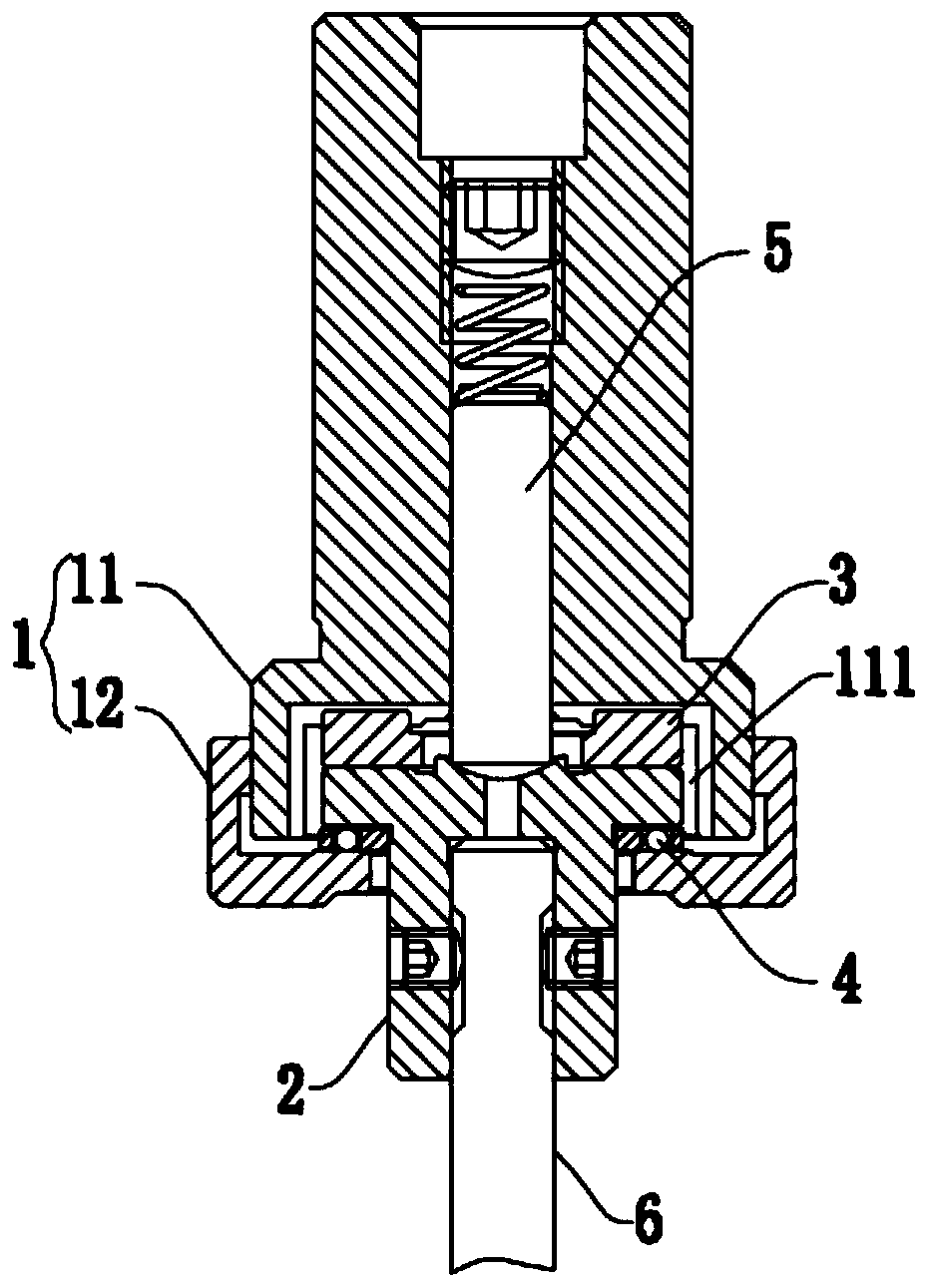

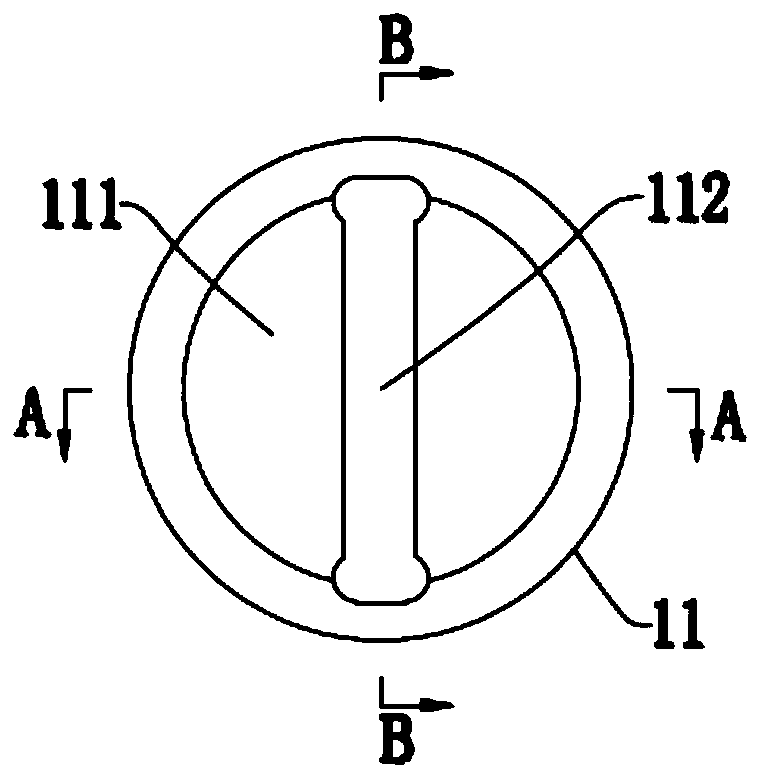

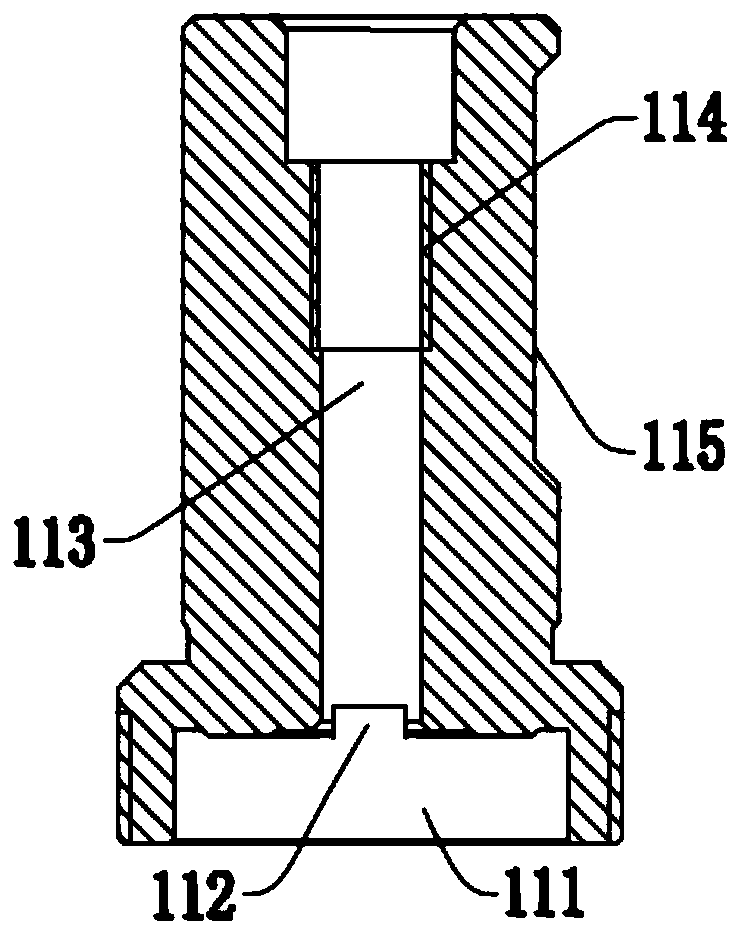

[0052] A floating connector such as figure 1 and Figure 14 As shown, it includes a connecting body assembly 1 and a secondary connecting body 2. The connecting body assembly 1 includes a main connecting body 11 and a lower cover 12; the head of the secondary connecting body 2 is accommodated in the lower end of the main connecting body 11. Inside the floating chamber 111; the lower cover 12 is sleeved outside the secondary connecting body 2, and is detachably connected to the lower end of the main connecting body 11; the floating chamber 111 is also provided with a cross block 3, the The intersection block 3 is slidably connected between the bottom of the floating chamber 111 and the top of the secondary connecting body 2, between the secondary connecting body 2 and the crossing block 3, and between the crossing block 3 and the main connecting body Relative sliding in the horizontal direction can occur between 11; between the secondary connecting body 2 and the cross block 3...

Embodiment 2

[0059] The basic structure of the floating connector of this embodiment is the same as that of Embodiment 1. The difference and improvement lies in that, after the cooperation between the top positioning boss 31 and the bottom positioning groove 112, a space is reserved for the cross Block 3 and the secondary connecting body 2 float up and down the clearance allowance.

[0060] By setting the gap margin, the auxiliary connecting body 2 and the cross block 3 have a floating space for floating up and down, so that the tool has the ability to float up and down, so as to compensate for the thermal deformation of the machine tool, the installation of the workpiece, etc. in the vertical direction. error, optimize the processing effect, and improve the processing accuracy.

Embodiment 3

[0062] A kind of floating connector of this embodiment, the basic structure is the same as embodiment 1 and 2, the differences and improvements are as follows: figure 1 and Figure 14 As shown, it also includes a floating centering assembly 5 arranged in the central hole 113 of the main connecting body 11, the floating centering assembly 5 includes a centering pin 51 and a spring 52, and the lower end of the centering pin 51 passes through Pass through the middle of the intersection block 3 and push into the centering groove 22 at the top center of the auxiliary connecting body 2; the lower end of the spring 52 is sleeved on the upper end of the centering pin 51, and the spring 52 is under compression state. The expansion and contraction of the spring 52 makes the centering pin 51 have a floating displacement in the vertical direction. In this embodiment, the central hole 113 is coaxial with the main connecting body 11 and has a sealed upper end, and the upper end of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com