Solid wax rod constant-pressure automatic wax coating device adopting torque motor

A technology of torque motor and wax coating device, which is applied to metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of waste of liquid wax, complicated structure of sliding table, difficult to clean, etc., and achieves easy and convenient operation and control. The system is simple and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

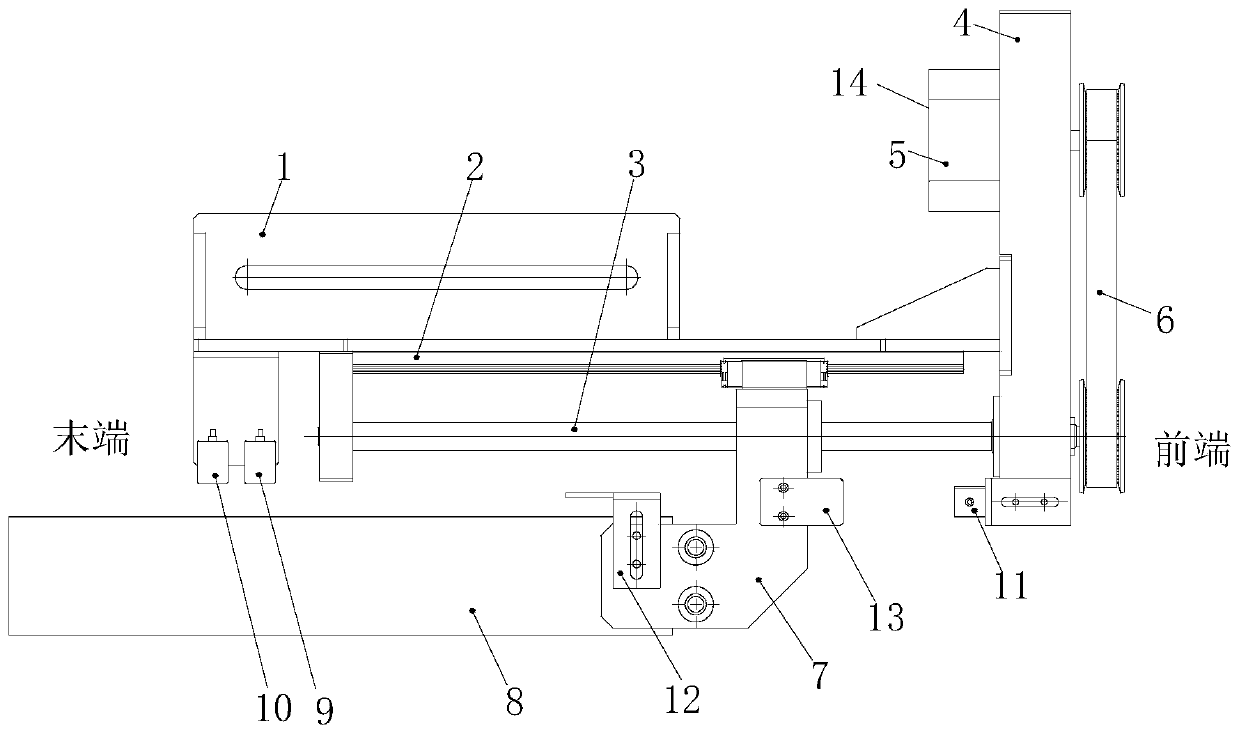

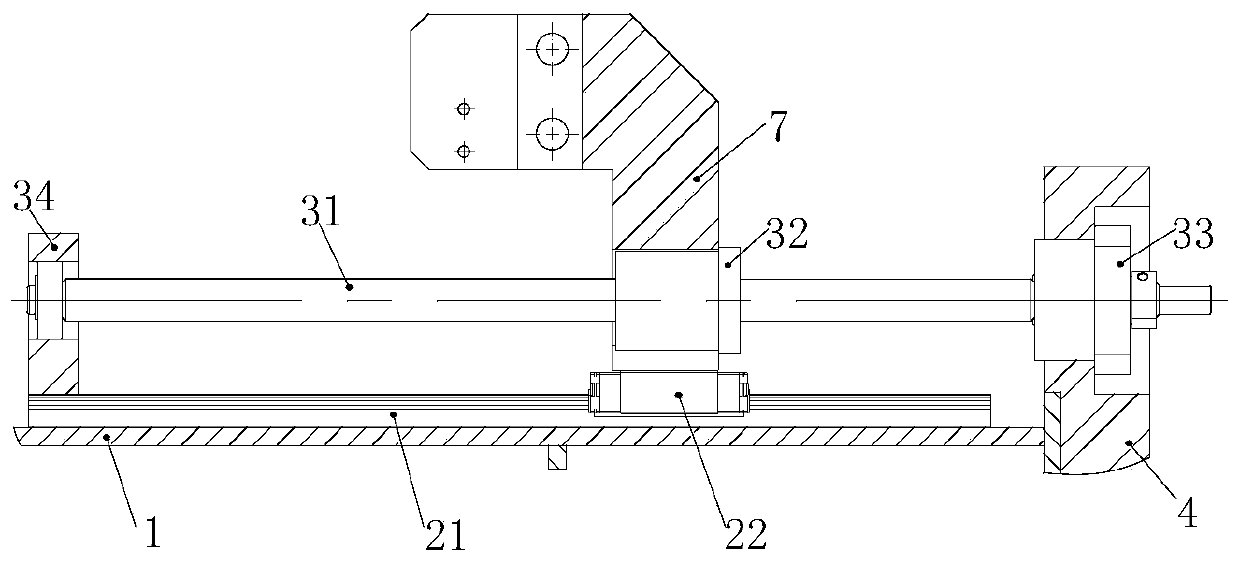

[0033] Combine below Figure 1-4 The technical solution provided by the present invention is described in more detail.

[0034] Such as figure 1 As shown, it is a kind of solid wax bar constant pressure automatic waxing device using a torque motor according to an embodiment of the present invention, which includes:

[0035] fixed bracket 1,

[0036] The linear guide rail guide assembly 2, the ball screw drive assembly 3, the solid wax strip clamping device 7 installed on the fixed bracket 1, and the sensor sensing piece 12 and the limit sensing piece 13 installed on the solid wax strip clamping device 7, A solid wax strip 8 is fixed on the solid wax strip clamping device 7 .

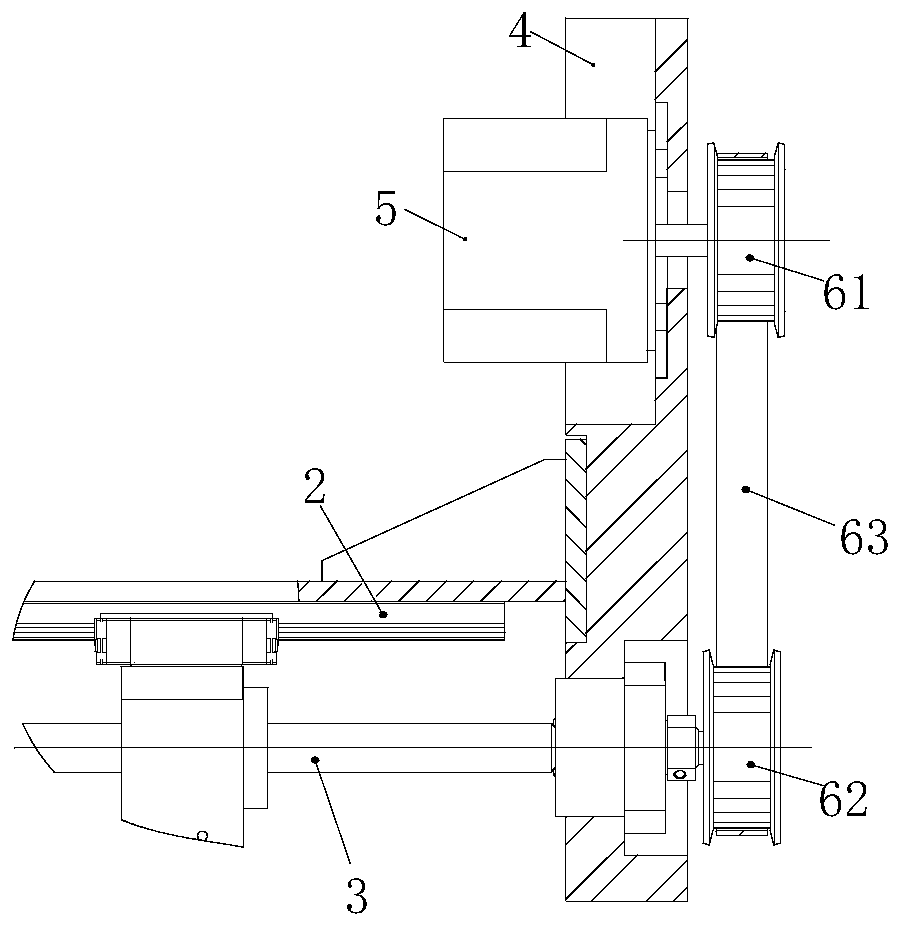

[0037] A torque motor drive assembly is also fixed on the fixed bracket 1, and the torque motor drive assembly includes a motor mounting plate 4 fixedly connected with the fixed bracket 1, a torque motor 5 and a synchronous belt transmission assembly arranged on the motor mounting plate 4 6.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com