A hook type shot blasting machine for surface treatment of vehicle parts

A technology for surface treatment and components, applied in the field of hook shot blasting machines, which can solve problems such as unstable drive, large amount of one-time shot blasting, hook jamming and detachment, etc., to achieve commission efficiency and improve shot blasting effect and processing efficiency, the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

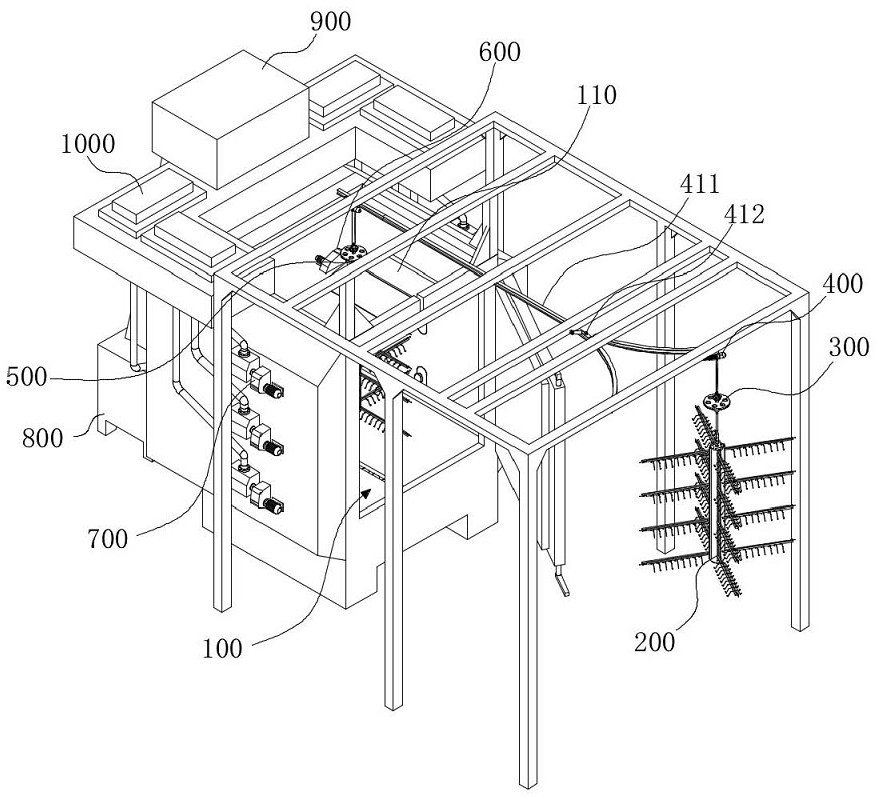

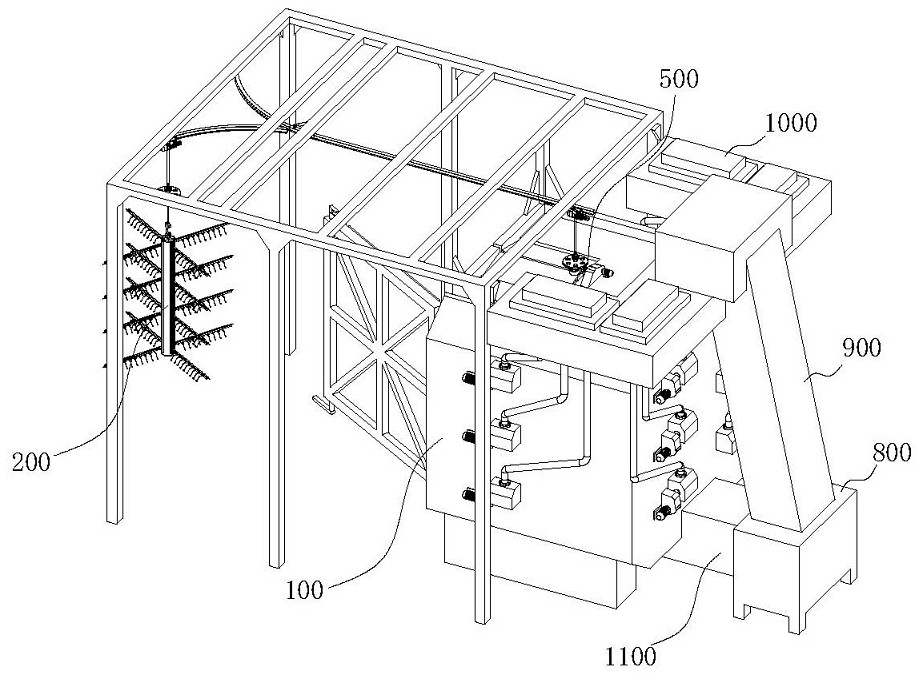

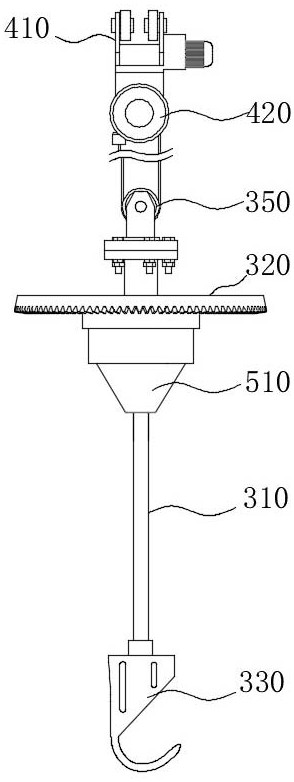

[0048] refer to Figure 1-4 , in the embodiment of the present invention, a hook-type shot blasting machine for surface treatment of vehicle parts is proposed, including a hanger 200 for hanging workpieces, the hanger 200 is hooked on the hook assembly 300, and the hanger The hook assembly 300 is connected to the conveying unit 400, and the conveying unit 400 is used to transport the hook assembly 300 into and out of the shot blasting treatment chamber 100, and the shot blasting treatment chamber 100 is used to carry out shot blasting treatment on the workpieces transported into it, and will be placed in the shot blasting treatment chamber 100 records the position of the hook assembly 300 as the working position when performing shot blasting on the workpiece inside it, and the shot blasting treatment chamber 100 is equipped with a rotation drive mechanism 600, which is used to drive the crane located at the work position. Hook assembly 300 rotations;

[0049] It also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com