Variable-precision screw-extruding additive manufacturing equipment with stirring and anti-blocking functions

A technology of additive manufacturing and equipment, which is applied in the field of screw extrusion variable precision additive manufacturing equipment, can solve the problems of unsuccessful material transportation, unevenness, blockage, etc., to promote material transportation, improve stability and stability, prevent The effect of material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

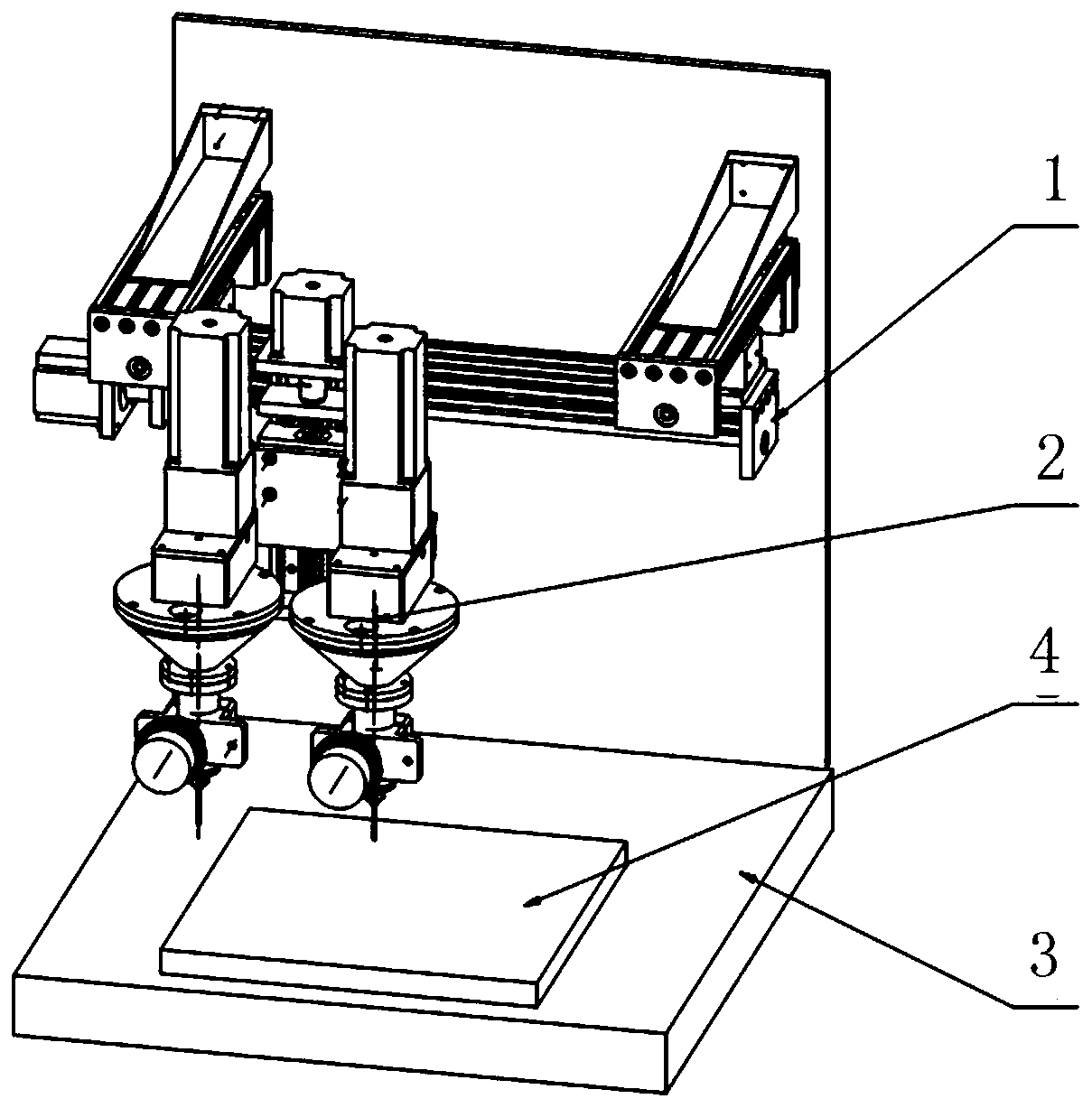

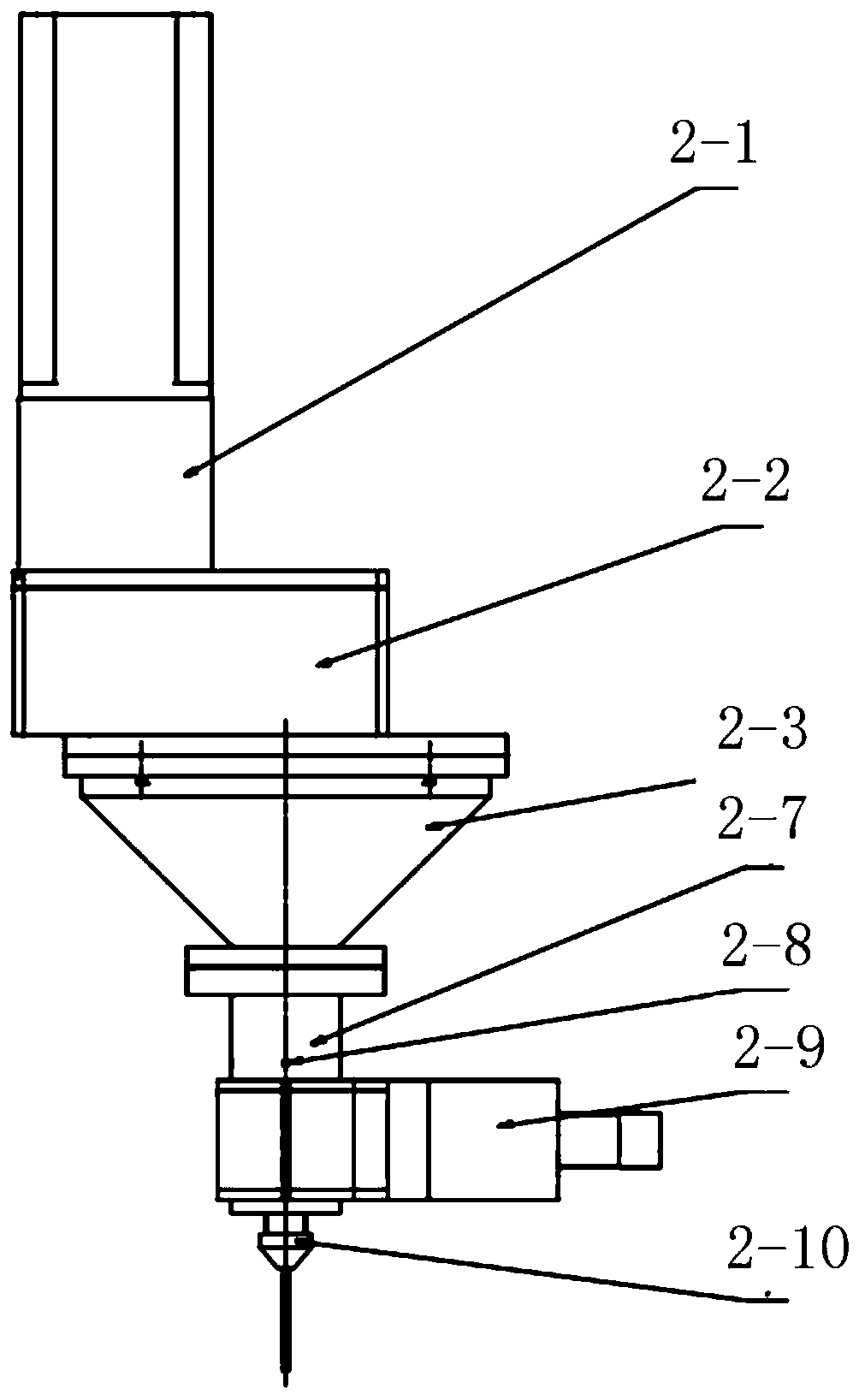

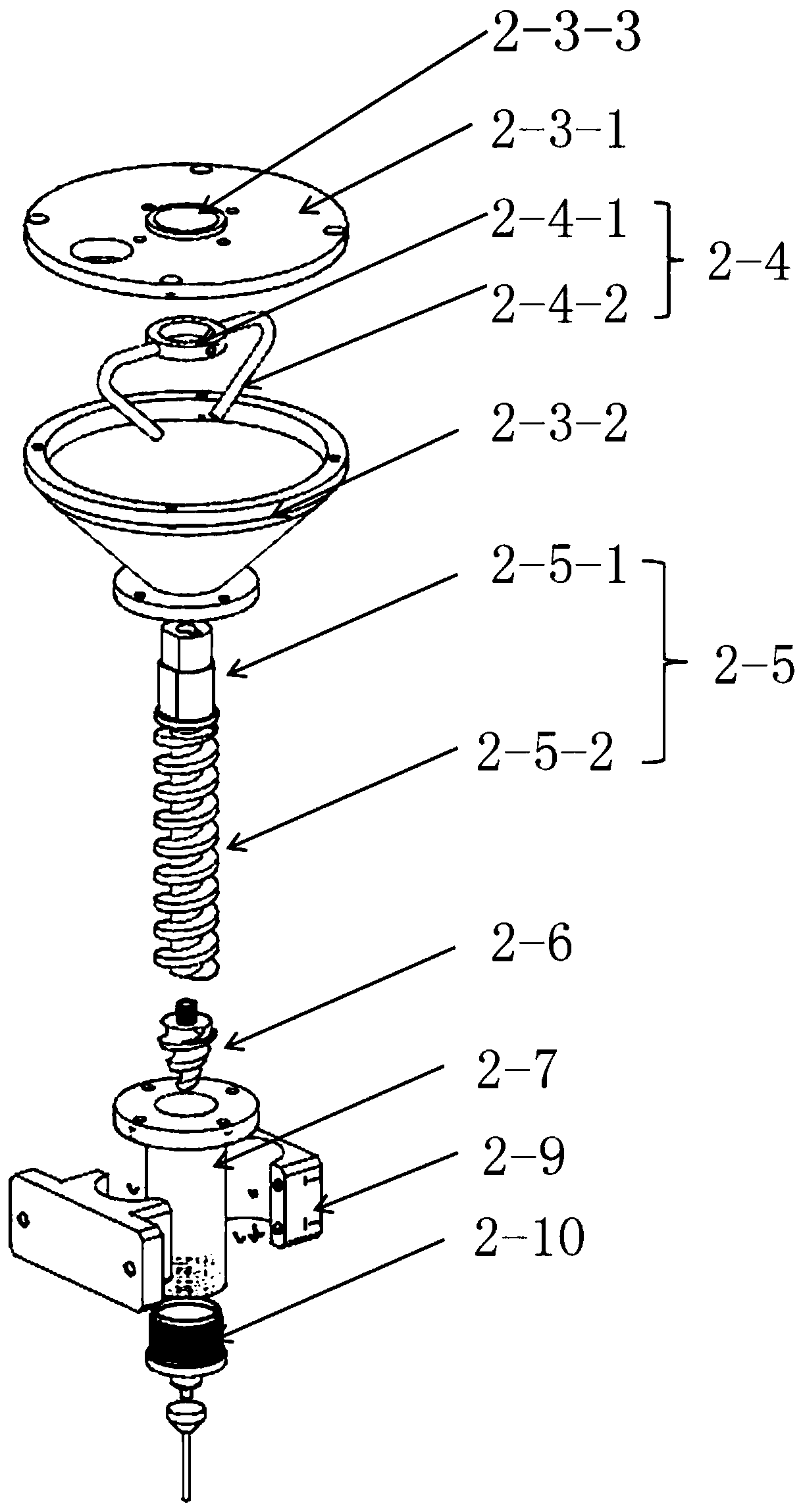

[0039] Such as figure 1 The additive manufacturing equipment shown includes: a three-dimensional mobile platform 1, two extrusion units 2, a frame 3, a printing platform 4, a three-dimensional mobile platform 1 is fixed on the frame 3, and the extrusion unit 2 is fixed on a three-dimensional mobile On the platform 1 , the printing platform 4 is placed under the extrusion unit 2 , and the printing platform 4 is fixed above the frame 3 . The three-dimensional mobile platform adopts the known screw guide rail structure, which is composed of four sets of second motors, couplings, screw rods, guide rails and loading racks. The second motor is connected to the screw rod through the coupling, and the screw rod is connected to the load The rack is connected, and the stage is connected with the guide rail. Driven by the second motor, the three-dimensional movement of the carrier can be realized. The movement space of the three-dimensional mobile platform 1 is 300×400×200 mm, and the s...

Embodiment 2

[0047] The difference from Example 1 is that the heating device is replaced by an ultrasonic vibration device, and no temperature measuring hole is provided. There is an ultrasonic vibration device outside the barrel, which can promote the transportation of high-viscosity materials based on the anti-friction effect of ultrasound. The equipment provided in this embodiment is suitable for conveying high-viscosity materials.

Embodiment 3

[0049] The difference from Example 1 is that a second opening is provided on the cover of the storage bin, through which the second opening is connected with the external storage bin to ensure that the material in the storage bin is sufficient to realize continuous feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com