Environment-friendly high-speed train compartment wall cabinet and preparation method

A kind of inter-train, environment-friendly technology, applied in the field of rail transit, can solve the problems of the adverse impact of log resources on the earth's ecological environment, the negative impact on human health and the environment, and the inability to fully adapt to the bending strength, so as to enhance safety and reliability. , The effect of protecting health and preventing interference of electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

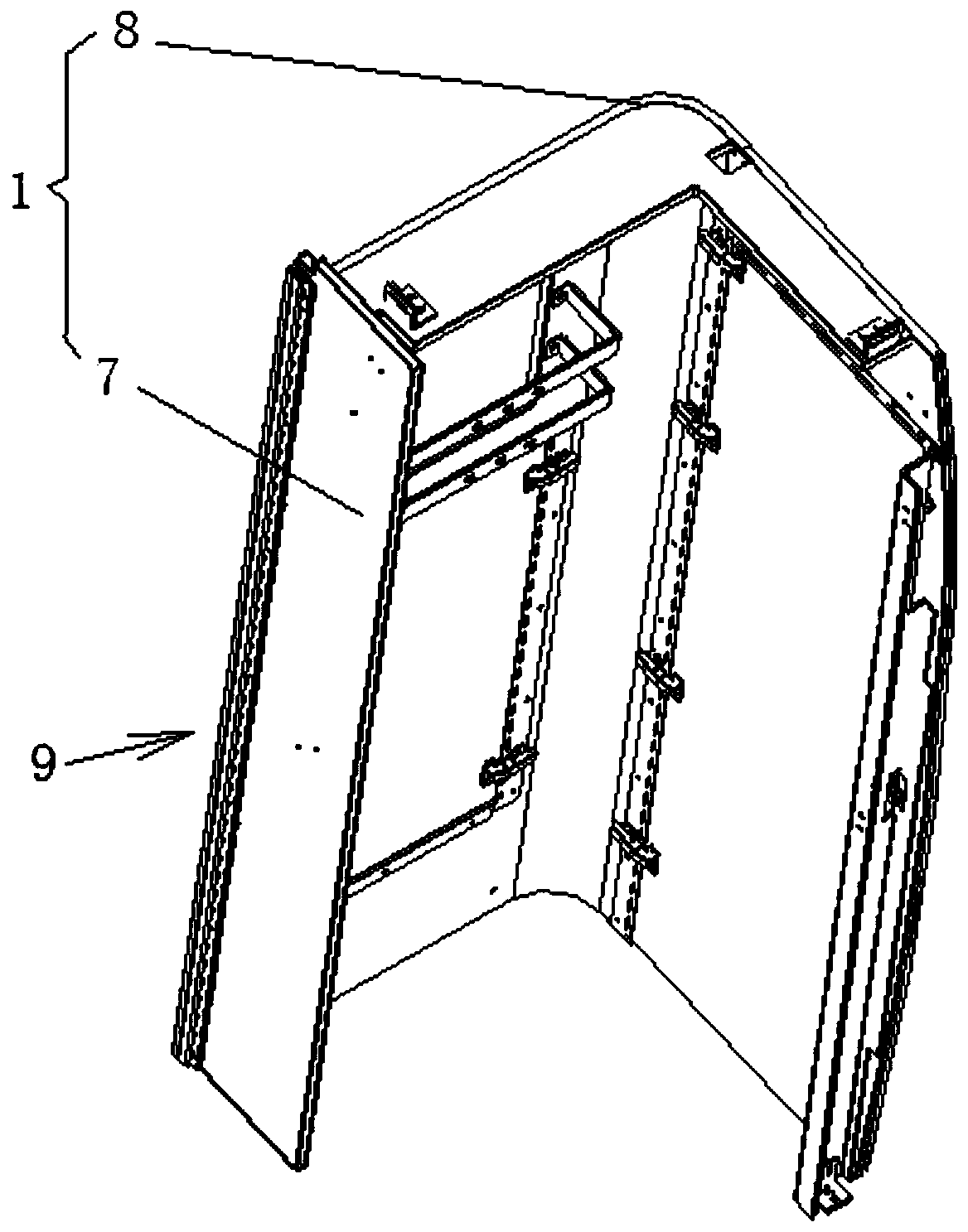

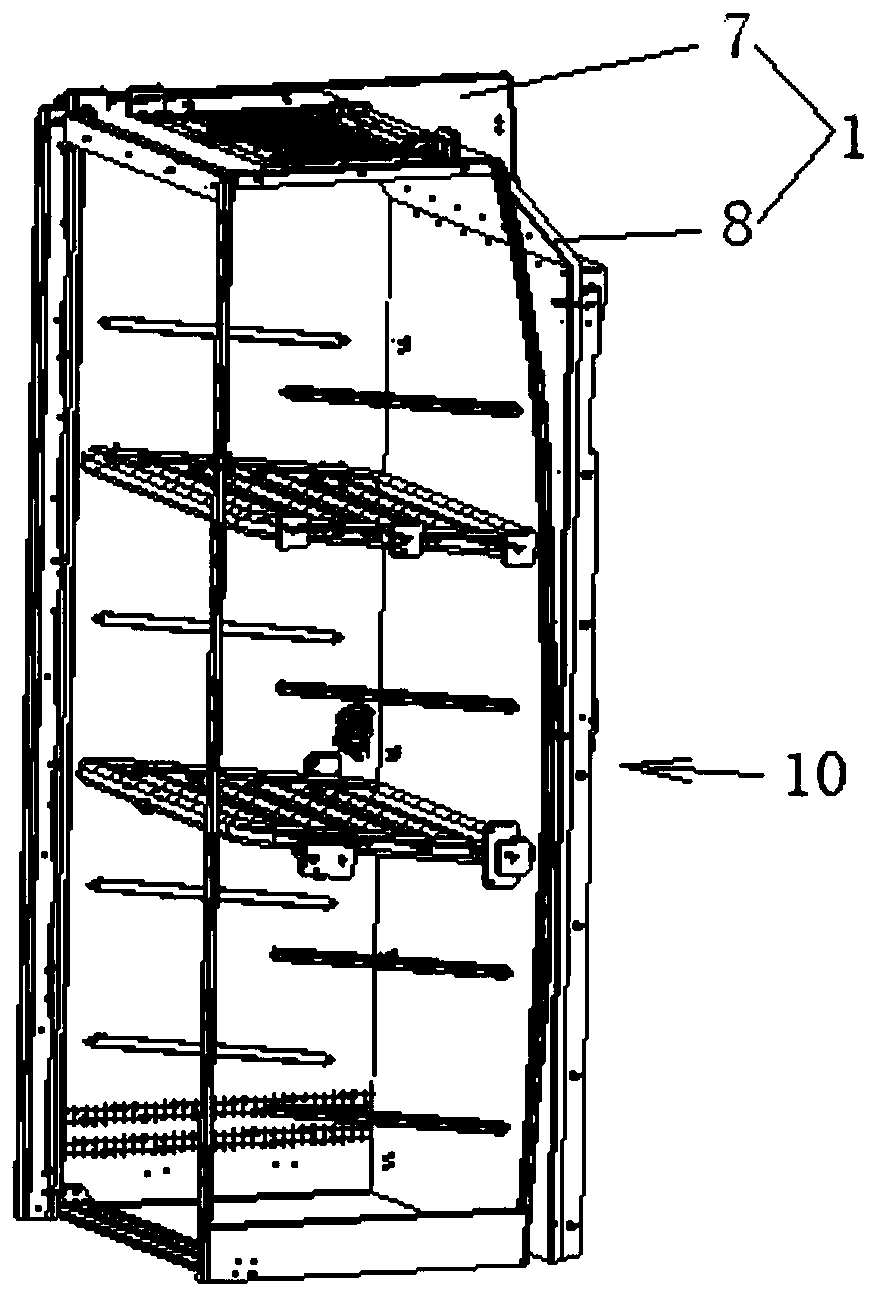

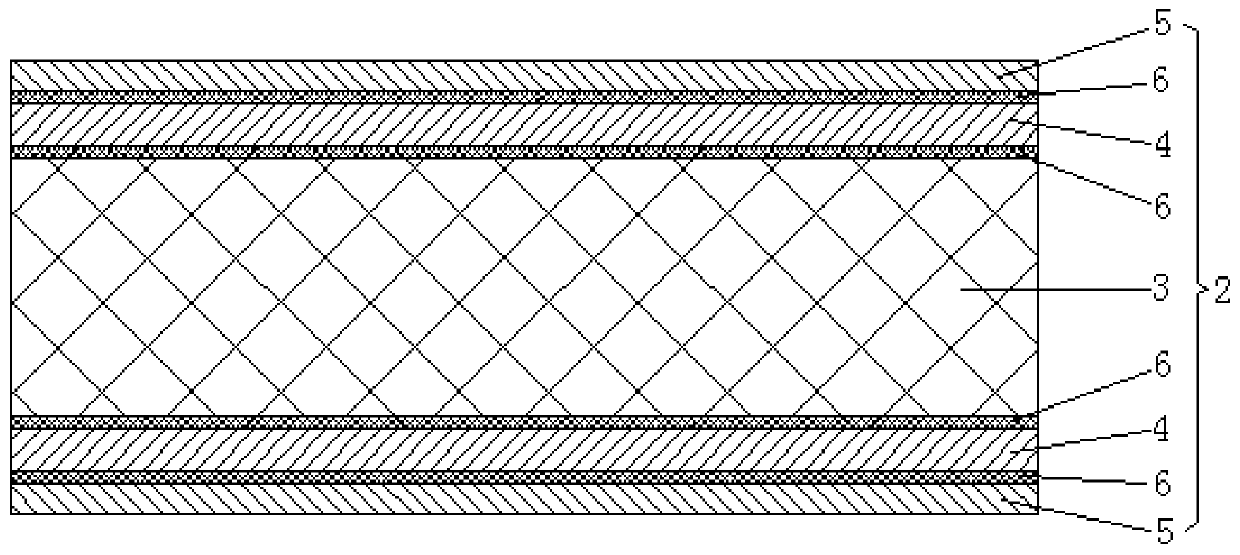

[0057] Such as Figures 1 to 6 Shown is an embodiment of an environment-friendly high-speed train partition cabinet of the present invention, which includes a cabinet body 1 assembled and connected by a number of hemp fiber composite boards 2, the hemp fiber composite board 2 has a laminated structure, so The laminated structure includes an intermediate layer 3, a transition layer 4 disposed on both ends of the intermediate layer 3, and a veneer layer 5 disposed on the outer end of the transition layer 4, and the two ends of the intermediate layer 3 have bonding Layer 6, a bonding layer 6 is arranged between the veneer layer 5 and the transition layer 4; wherein, the middle layer 3 is a hemp fiber board, the transition layer 4 is a solid wood board, and the veneer layer 5 It is a fireproof board, and the bonding layer 6 is PP non-woven fabric.

[0058] In the above technical scheme, the board of the wall cabinet is mainly made of hemp fiberboard, and solid wood boards and fir...

Embodiment 2

[0071] Such as Figures 1 to 6 Shown is the embodiment of the preparation method of a kind of environment-friendly type high-speed train wall cabinet, comprises following method step:

[0072] The first step, prefabricated hemp fiber felt 60;

[0073] The second step, making the middle layer: laminate the hemp fiber felt 60 in multiple layers, and then spread a layer of PP non-woven fabric on both sides of the laminated hemp fiber felt, and then carry out thermocompression molding to make it as the middle layer 3 The hemp fiber board; wherein, when making the middle layer of the hemp fiber composite board used as the electrical cabinet, an electromagnetic shielding layer 20 is also placed between two adjacent two hemp fiber mats in the multi-layer laminated hemp fiber mat, so Described electromagnetic shielding layer 20 comprises flexible wire mesh 22, the adhesive layer 21 that is respectively arranged on the both sides of described flexible wire mesh 22, and described adhes...

Embodiment 3

[0090] Carry out performance test for adopting above-mentioned embodiment 1 and 2 a kind of environment-friendly type high-speed train compartment wall cabinet (get its fiberboard as sample) manufactured, obtain result as follows:

[0091]

[0092]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com