Airship landing gear

A landing gear and airship technology, applied in the field of airship landing gear, can solve the problems of difficult processing, heavy weight, complex structure of airship landing gear, etc., and achieve the effect of flexible installation, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

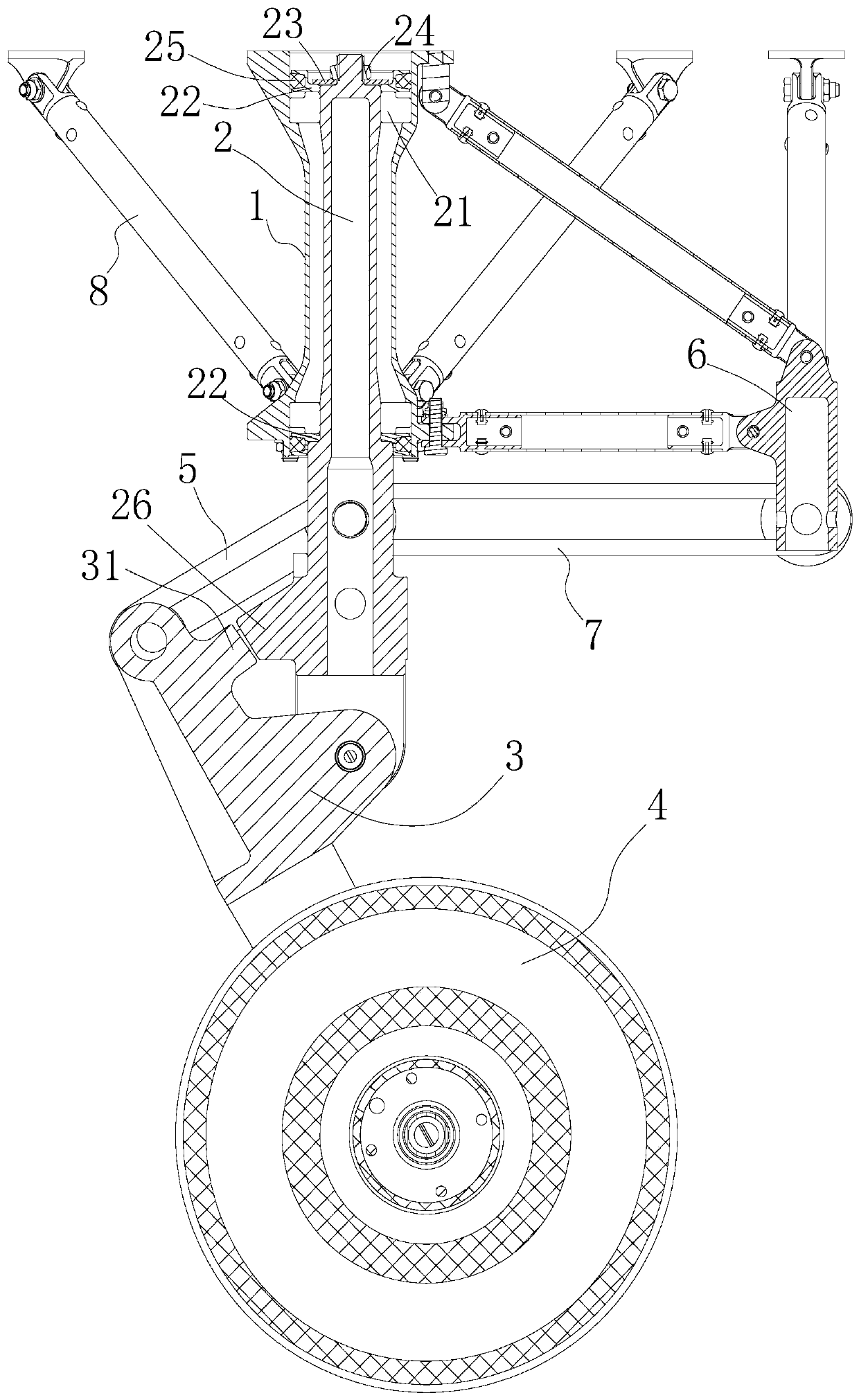

[0058] like figure 1 Shown, a kind of airship undercarriage comprises sleeve 1, rotating mandrel 2, wheel fork 3, wheel 4, first elastic body 5, centering fixing part 6, second elastic body 7, pull rod 8, for convenience For understanding and description, the direction of the airship is on the left.

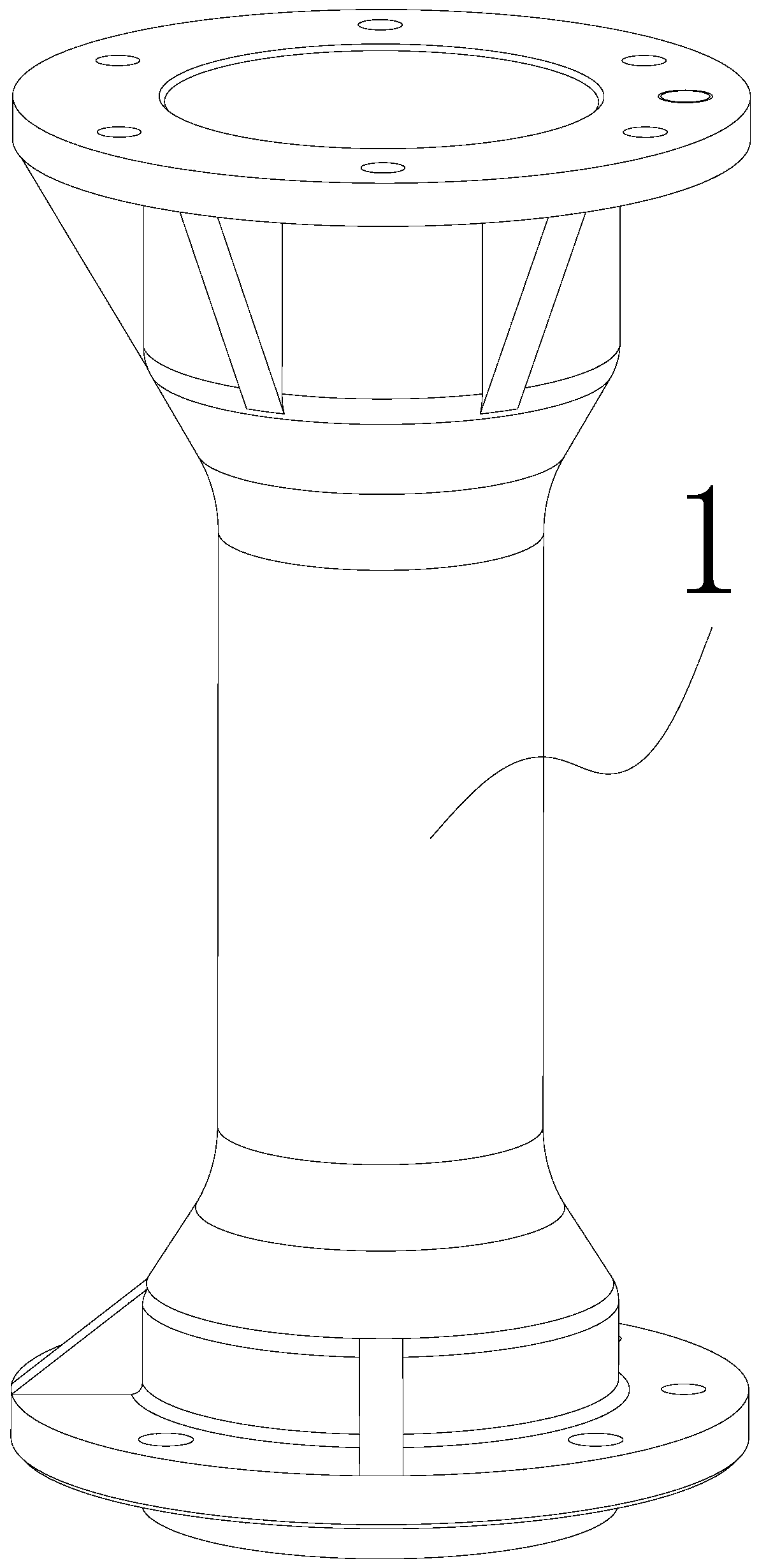

[0059] to combine figure 1 , 2 , the sleeve 1 is a hollow cylindrical part, the upper and lower ends of the sleeve 1 are provided with flanges, and the inner two ends of the sleeve 1 are provided with bearing steps, and the sleeve 1 is vertically arranged on the airship body Bottom, the upper end of the sleeve 1 is connected to the bottom of the airship body by bolts, and a tie rod 8 is arranged between the lower end of the sleeve 1 and the bottom of the airship body. There are four pull rods 8, and the four tie rods 8 are evenly distributed on the sleeve around 1.

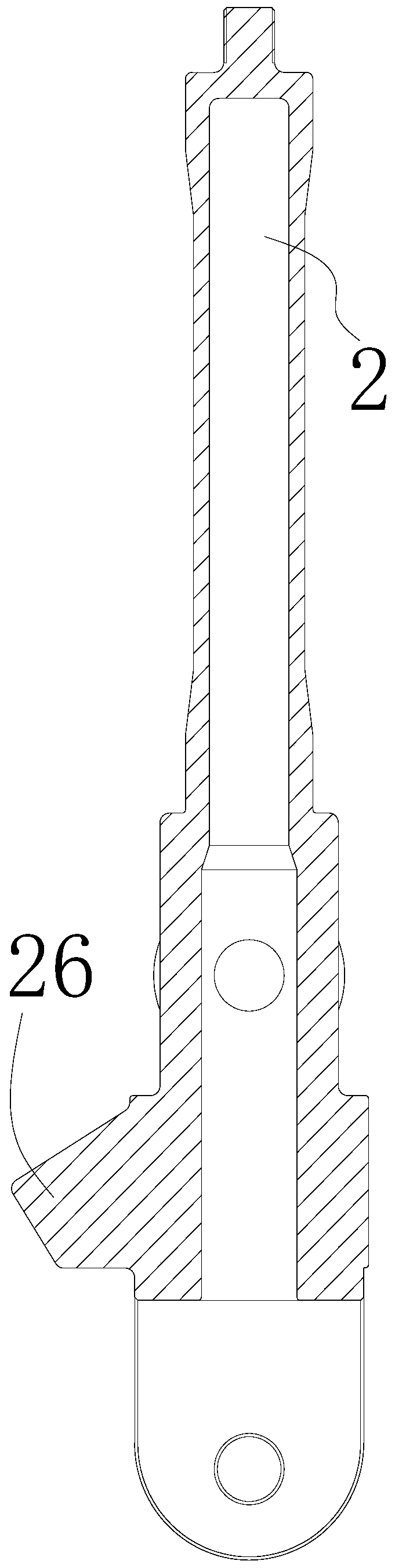

[0060] to combine figure 1 , 3 , 4. A rotating mandrel 2 is rotatably installed in the sleeve 1. The rotatin...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is:

[0076] Both the first elastic body 5 and the second elastic body 7 are extension springs, two machine wheels 4 are provided, the axes of the two machine wheels 4 are located on the same straight line, and the two are arranged side by side.

[0077] working principle:

[0078] In the airship landing gear of the present invention, when the airship lands, the wheel 4 contacts the ground, and the wheel 4 generates an upward supporting reaction force. amplitude swing, the first elastic body 5 will produce a certain deformation to resist the swing of the wheel fork 3, and then play a buffering role, while being able to withstand, absorb and consume the impact and bump energy of the airship when it is landing and gliding. In addition, Under the action of the second elastic body 7, when the moments generated by the second elastic body 7 on both sides of the rotating mandrel 2 are equal in size and opposite in direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com