One-way moisture-conducting and heating fiber quilt core and preparation method thereof

A technology for hygroscopic heating fibers and heating fibers, which can be used in bed sheets, applications, non-woven fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

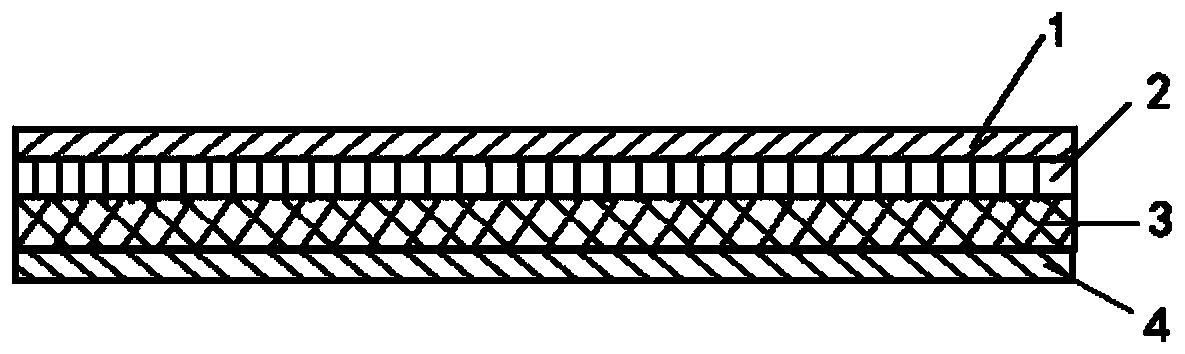

Image

Examples

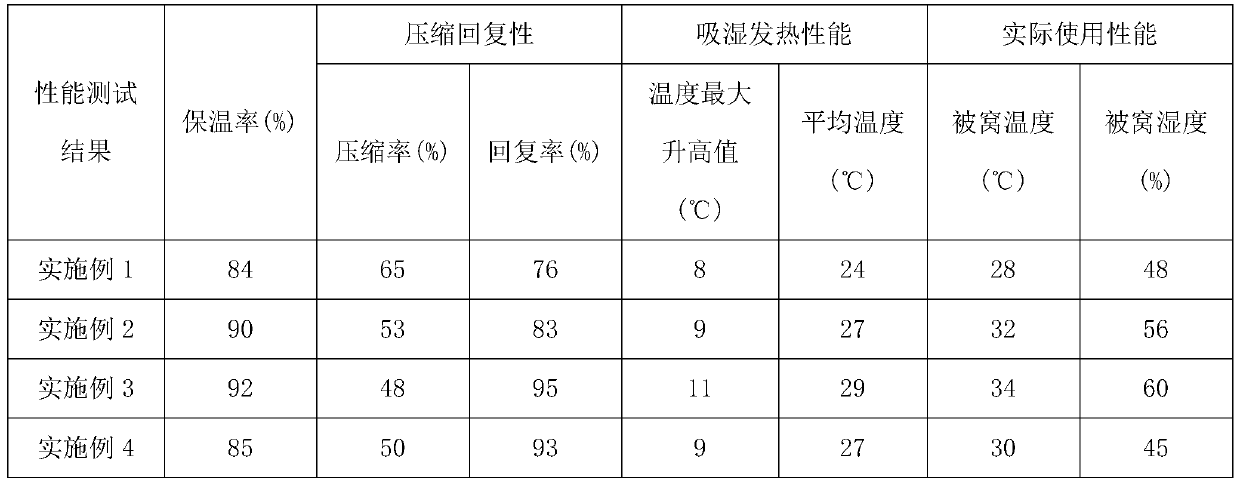

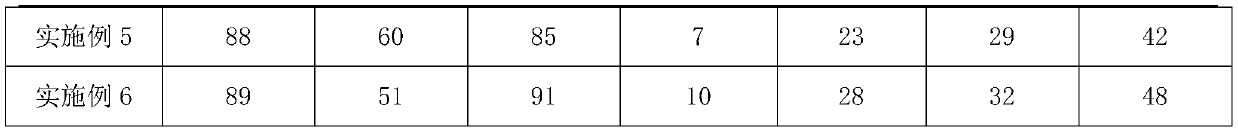

Embodiment 1

[0047] (1) Preparation of the first super hygroscopic quick-drying lightweight fiber web layer: After using polyester fiber with an average fineness of 1.38D and a fiber length of 55mm, cross-shaped special-shaped cross-section polyester fiber is used for feeding, carding and laying, and the weight percentage is obtained. The fiber web layer is 20% of the total fiber content of the core.

[0048] (2) Preparation of the second cotton fiber mixed mesh layer: the long-staple cotton fiber and the cross-shaped special-shaped polyester fiber are respectively opened, and then mixed, combed, and laid according to the ratio, and the obtained weight percentage is 30% of the total content of core fibers in the fiber web layer, of which the proportion of fibers with special-shaped cross-section is 5%.

[0049] (3) Preparation of the third hygroscopic heating fiber mixed mesh layer: the hygroscopic heating fibers and the three-dimensional crimped fibers are respectively opened, and then mi...

Embodiment 2

[0054] (1) Preparation of the first super hygroscopic quick-drying lightweight fiber web layer: After using polyester fiber with an average fineness of 1.38D and a fiber length of 55mm, cross-shaped special-shaped cross-section polyester fiber is used for feeding, carding and laying, and the weight percentage is obtained. The fiber web layer is 15% of the total fiber content of the core.

[0055] (2) Preparation of the second cotton fiber mixed mesh layer: the long-staple cotton fiber and the cross-shaped special-shaped polyester fiber are respectively opened, and then mixed, combed, and laid according to the ratio, and the obtained weight percentage is 20% of the total content of core fibers in the fiber web layer, of which the fibers with special-shaped section account for 5%.

[0056] (3) Preparation of the third hygroscopic heating fiber mixed mesh layer: the hygroscopic heating fibers and the three-dimensional crimped fibers are respectively opened, and then mixed, combed...

Embodiment 3

[0061] (1) Preparation of the first super hygroscopic quick-drying lightweight fiber web layer: After using polyester fiber with an average fineness of 1.38D and a fiber length of 55mm, cross-shaped special-shaped cross-section polyester fiber is used for feeding, carding and laying, and the weight percentage is obtained. The fiber web layer is 10% of the total fiber content of the core.

[0062] (2) Preparation of the second cotton fiber mixed mesh layer: the long-staple cotton fiber and the cross-shaped special-shaped polyester fiber are respectively opened, and then mixed, combed, and laid according to the ratio, and the obtained weight percentage is 25% of the total content of core fibers in the fiber web layer, of which the fibers with special-shaped section account for 15%.

[0063] (3) Preparation of the third hygroscopic heating fiber mixed mesh layer: the hygroscopic heating fibers and the three-dimensional crimped fibers are respectively opened, and then mixed, combe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap