Construction method of basement gravel filling grouting anti-floating anchor rod

A technology of anti-floating anchors and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, protection devices, etc., can solve the problems of poor anchor bolt quality, uneven and dense grouting body, easy to block pipes, etc., and achieve fast construction, The effect of reducing contract performance risks and low construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

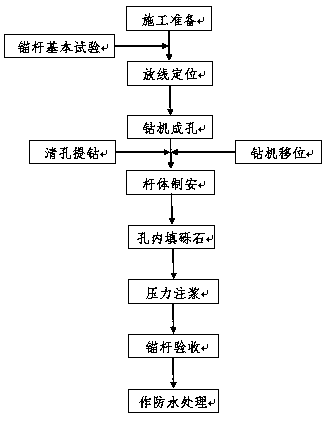

[0052] see Figure 1-4 , a construction method of anti-floating anchor rods for gravel filling and grouting in basements, using a rock bolter to drill with pipes, impacting to form holes, setting up anti-floating anchor rods for gravel filling and grouting to connect the base of a building or structure with the underlying bedrock As a whole, together with the upper structure, it resists the buoyancy of groundwater. The specific process is as follows:

[0053] (1) Construction preparation:

[0054] ① Leveling the anti-floating anchor construction site, removing ground obstacles, and the smoothness of the site meets the requirements for drilling rig slippage and drilling flatness;

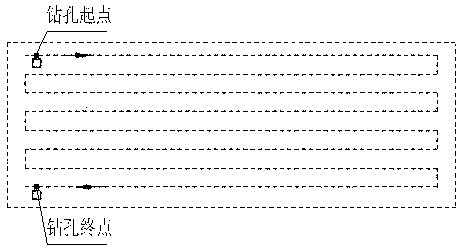

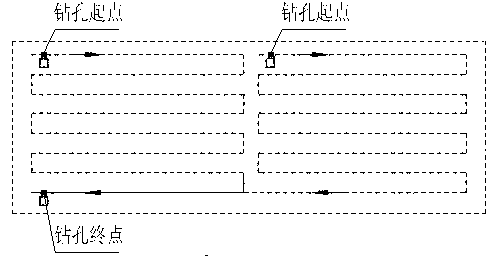

[0055] ② Number and map the bolt holes, and compile the drilling route map;

[0056] ③Complete equipment debu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com