Raft foundation bolt embedded structure and installation method

A technology of raft-shaped foundation and installation method, which is applied in the direction of basic structure engineering, construction, etc., can solve the problems of large geometric changes in bolt distribution, complex changes in bolt elevation, complex and changeable models and specifications, etc., and achieve convenient and firm erection and light control Flexible, Positioning Simple and Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

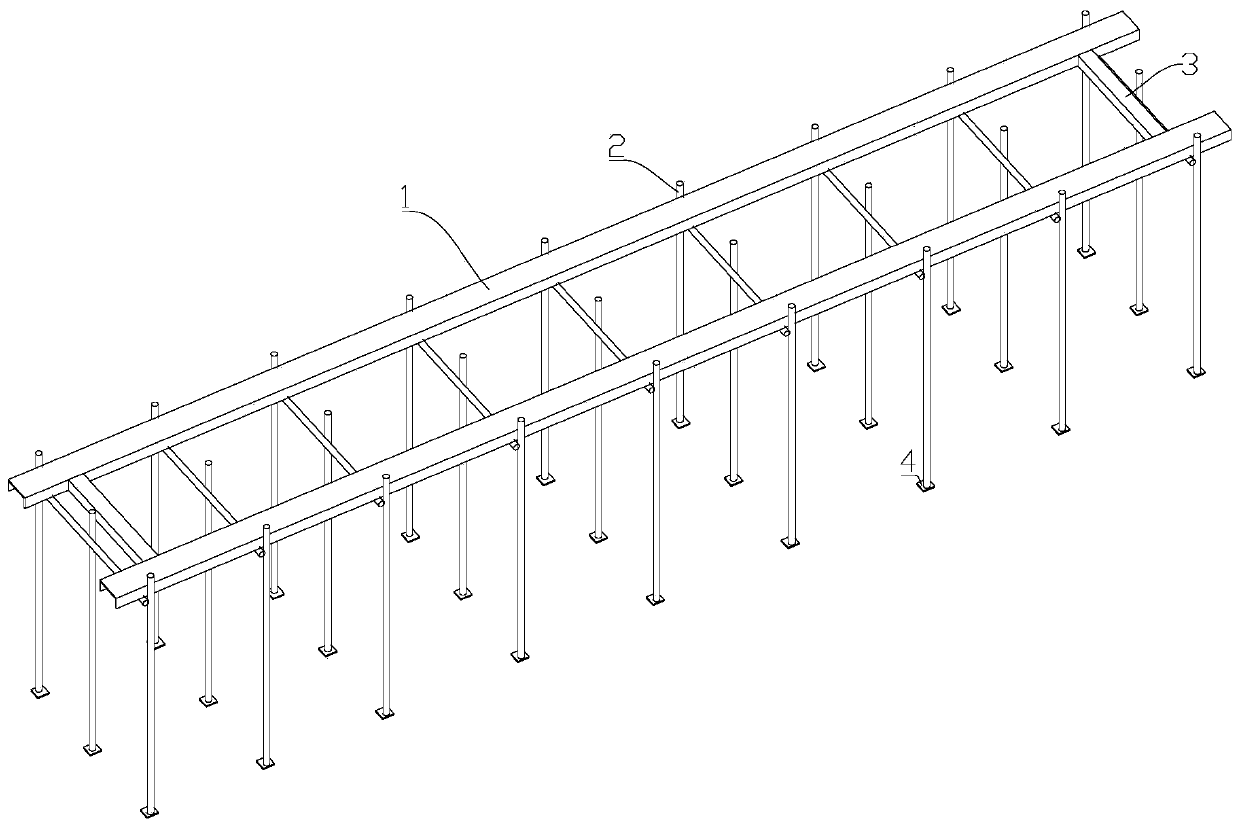

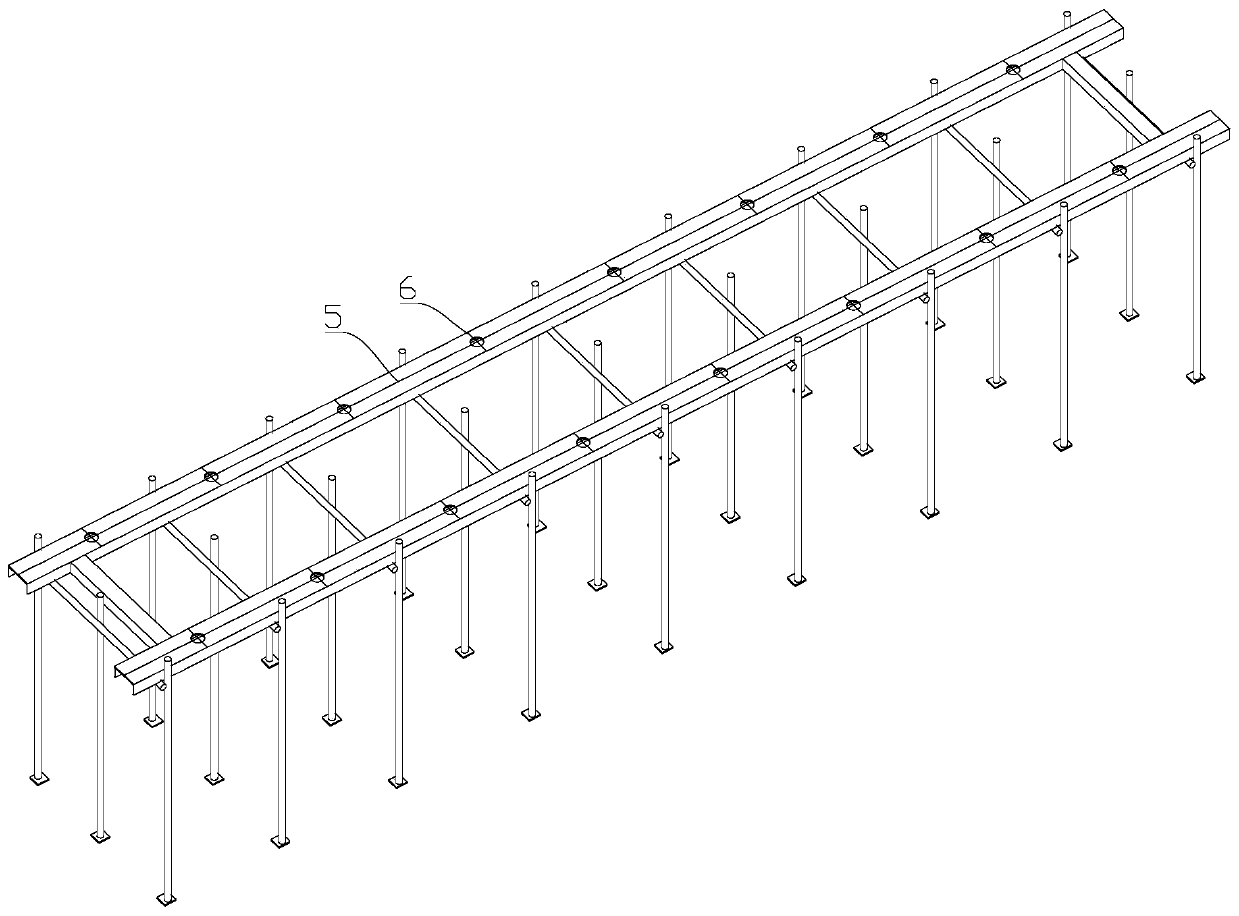

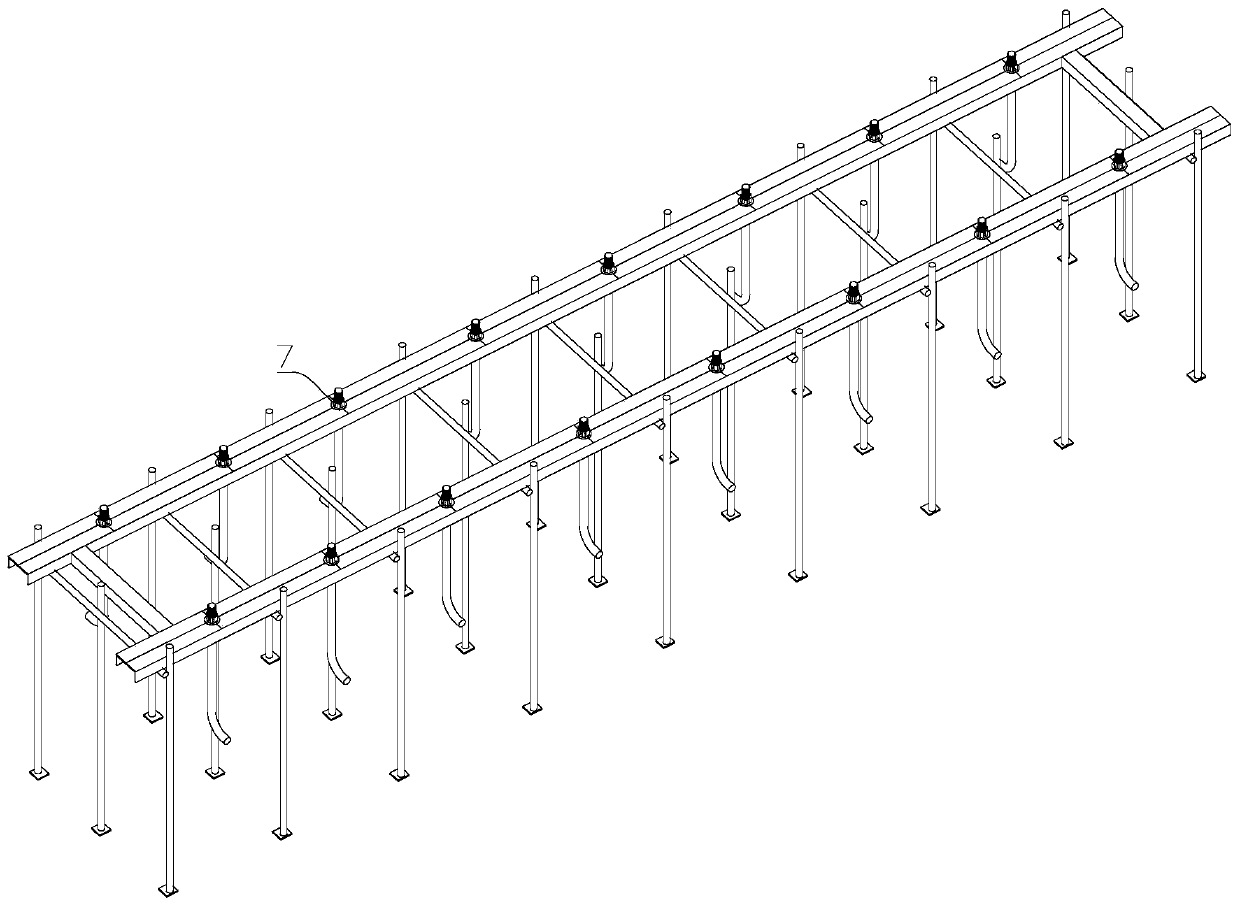

[0036] Such as Figure 1-Figure 3 As shown, the raft foundation embedded bolt installation method includes the following steps:

[0037] Preparation steps: carry out construction preparation according to the construction drawings;

[0038] Concrete cushion pouring step: After the bolt bracket is set to fix the iron piece 4, the cushion is poured;

[0039] Bolt bracket installation steps: fix the bolt bracket with the fixed iron piece 4, and use the fixed iron piece 4 as the fulcrum of the bolt bracket;

[0040] Drilling steps: first determine the installation position of the bolt, and drill the hole at the installation position of the bolt;

[0041] Bolt installation steps: Install the bolt at the installation position of the bolt, put o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com