Prestressed anchor bolt fan foundation reinforcement method

A foundation reinforcement and prestressing technology, applied in foundation structure engineering, foundation structure repair, construction, etc., can solve problems such as difficulty in ensuring quality, cracking of foundation concrete, inability to use commercial concrete, etc. The thickness of the root of the pick plate, the improvement of the stress condition, and the excellent reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

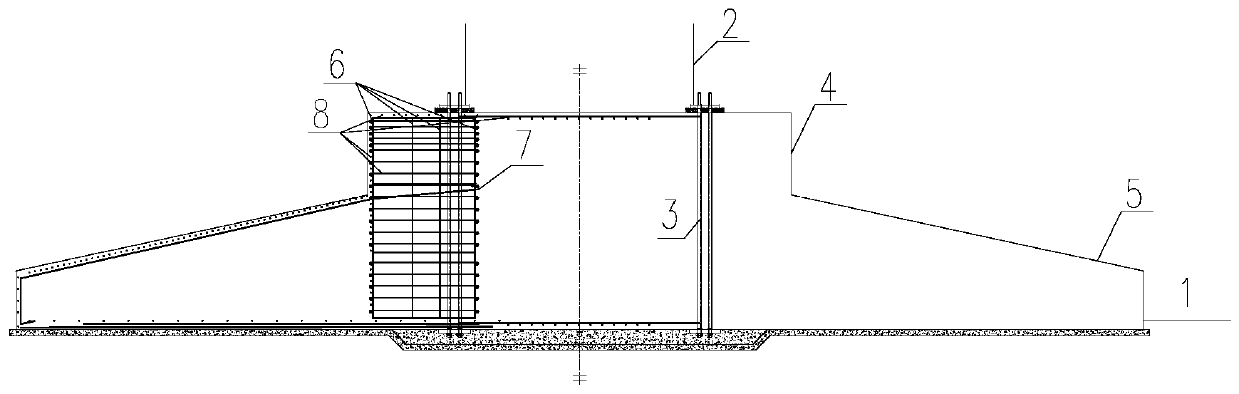

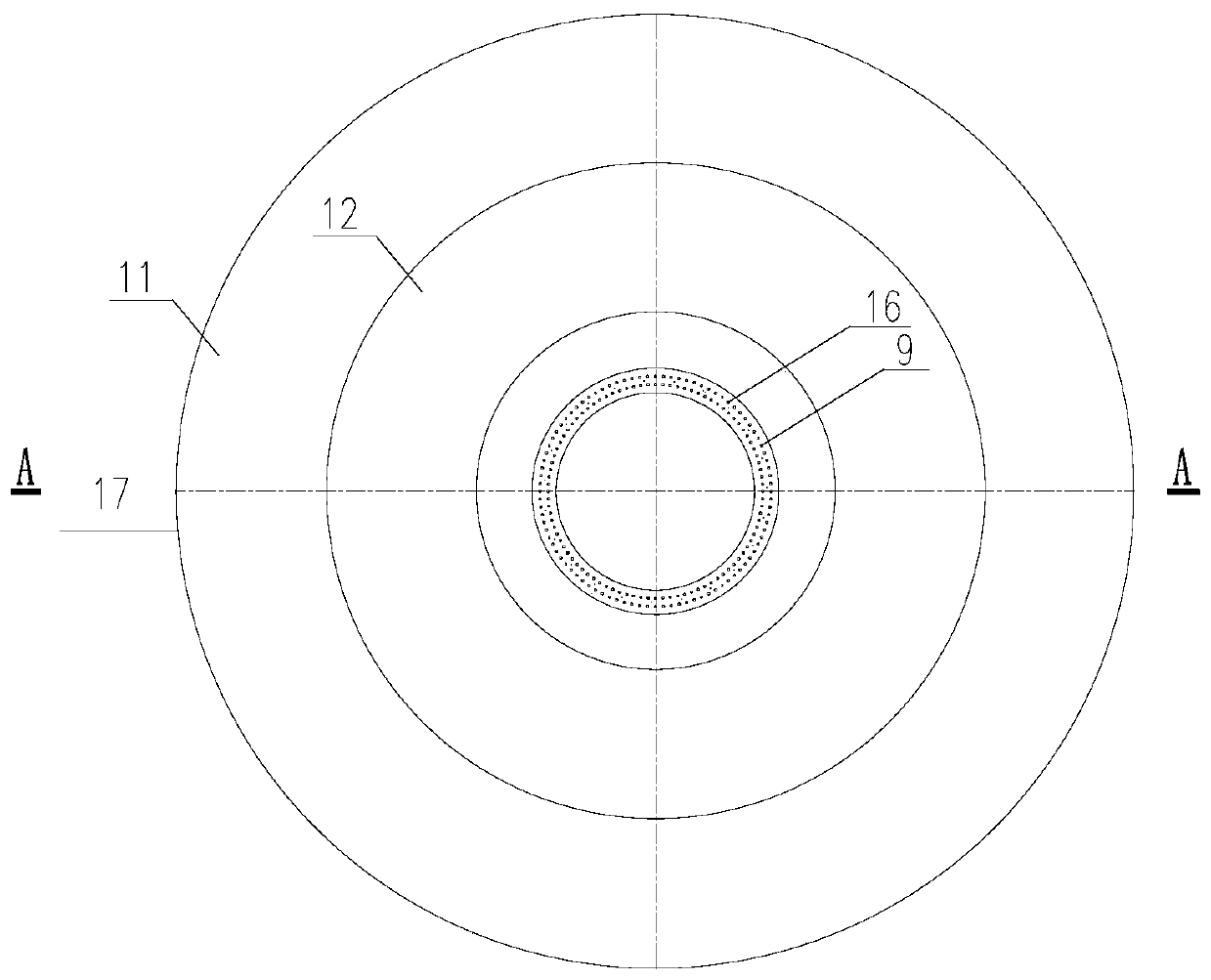

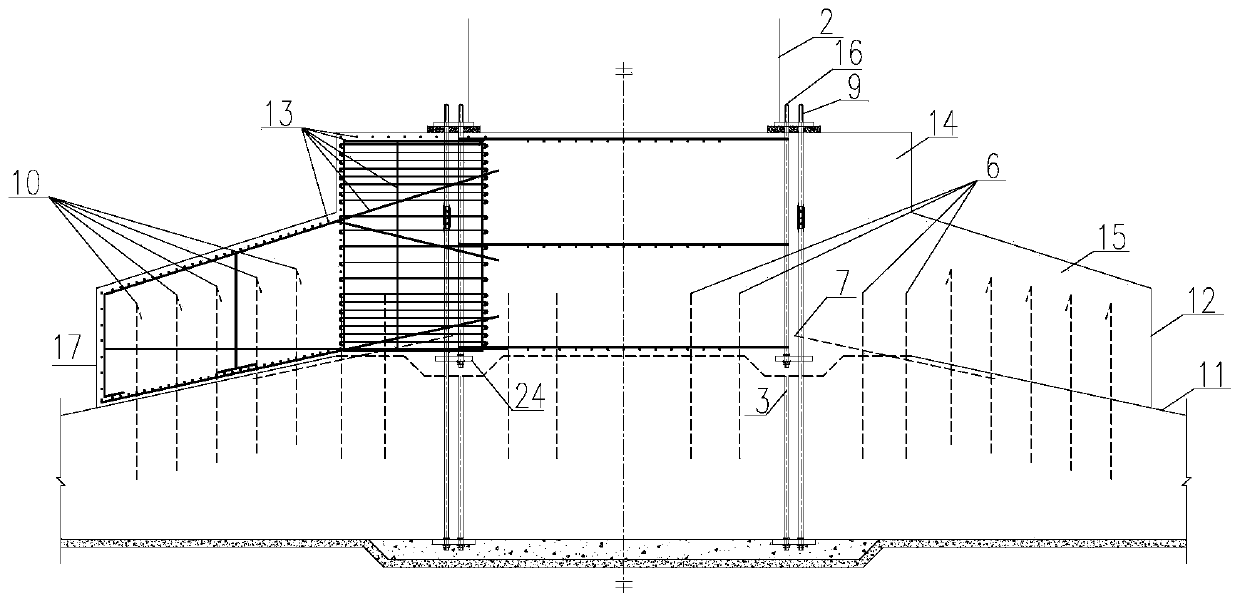

[0026] Figure 1-Figure 7 As shown, a prestressed anchor bolt fan foundation reinforcement method includes the following steps:

[0027] (1) For the original prestressed anchor bolt foundation 1 that needs to be reinforced, the original foundation pier 4 is removed, and the vertical reinforcement 6 extending from the original foundation into the pier and the radial reinforcement 7 from the original foundation extending into the pier are retained. And retain half of the original prestressed anchor bolts 3 at intervals, remove the other half of the original prestressed anchor bolts 3 and other steel bars 8, and retain the original foundation part as the lower foundation 11;

[0028] (2) Extend the retained original prestressed anchor bolt 3 to form a new extended anchor bolt 9;

[0029] The reserved prestressed anchor bolt 3 and the extended anchor bolt section 18 are connected through two thin nuts 19 and a long nut 20, and the connecting part is sleeved with a lap sleeve 21 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com