Pre-buried support-hanger device and manufacturing and construction mounting methods thereof

An installation method and a technology of support and hanger, which are applied in the direction of supporting machines, mechanical equipment, buildings, etc., can solve the problems of small force bearing surface of expansion screws, affect accurate positioning, increase construction cost, etc., achieve reduced construction strength, accurate positioning, The effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

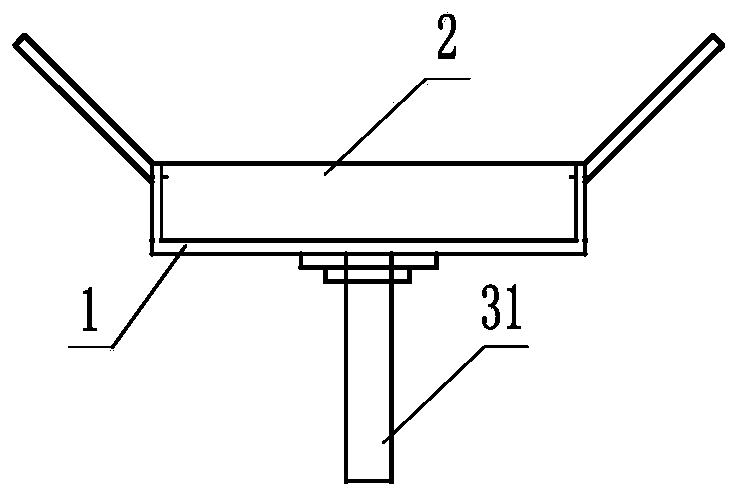

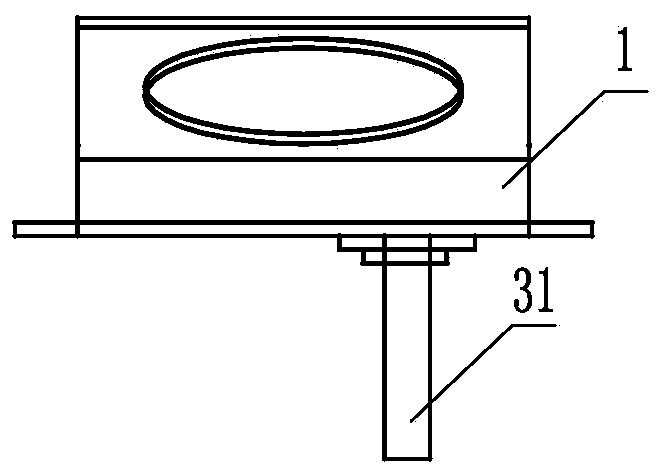

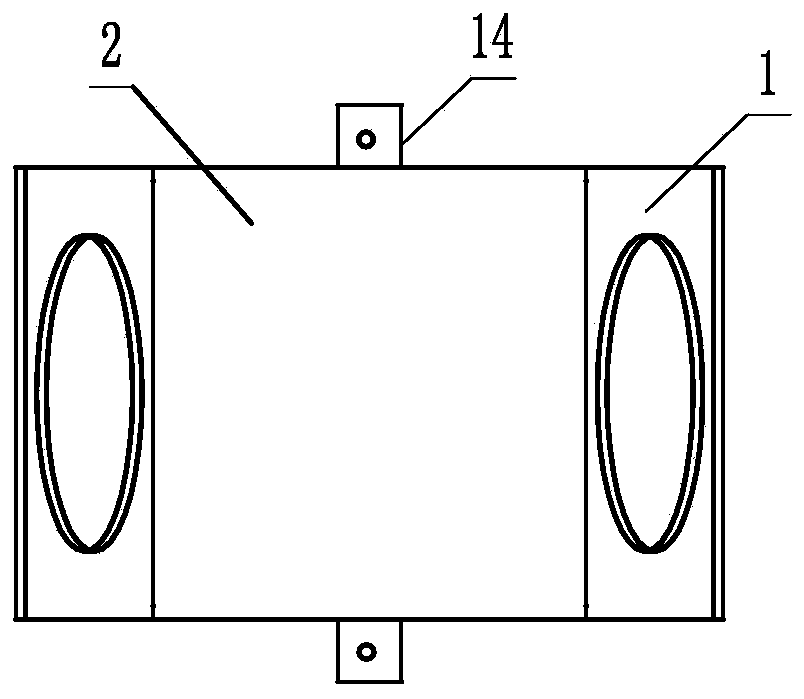

[0063] A pre-embedded support and hanger device, including a support and hanger main body I and a hanger assembly III; the support and hanger main body I includes a U-shaped base 1 and an inverted U-shaped cover groove 2, and the U-shaped base 1 includes a bottom plate 11 and the side vertical sides 12 symmetrically connected to the left and right sides thereof, the tops of the left and right side vertical sides are respectively connected to the extension plate 13, and the angle α formed between the extension plate and the side vertical side is 90-130°;

[0064] The middle part of the base plate 11 is provided with a cross-shaped slot 111, including longitudinal slots and transverse slots with the same slot width, and the front and rear ends of the base plate 11 are connected with lateral connecting plates 14;

[0065] Described inverted U-shaped cover groove comprises cover groove top plate 21 and the cover groove vertical edge 22 that is symmetrically connected in its front a...

Embodiment 2

[0075] A method for manufacturing a pre-embedded support and hanger device, comprising the steps of:

[0076] S11 Make a U-shaped base according to the specifications required by the design;

[0077] Press the rough surface of the thin steel plate as a whole to make a U-shaped base with a rough surface, the bottom plate, the side vertical edge and the extension plate integrated into one;

[0078] S12 Make an inverted U-shaped cover groove according to the specifications required by the design;

[0079] It is integrally pressed with a thin steel plate to make an inverted U-shaped cover trough that is integrated with the cover trough top plate and the vertical side of the cover trough;

[0080] S13 making the main body of the support and hanger;

[0081] S131 buckle the inverted U-shaped cover groove on the bottom plate of the U-shaped base through welding or bonding with an adhesive, so that the inverted U-shaped cover groove, the bottom plate and the vertical sides on both s...

Embodiment 3

[0097] S2 A construction and installation method for a pre-embedded support and hanger device, the steps are:

[0098] S21 When binding the steel bars at the bottom of the floor slab, according to the design requirements, mark the position where the embedded support and hanger device needs to be installed;

[0099] S22 Install the main body of the embedded support and hanger;

[0100] Install the support and hanger main body made in step S13 in the bottom steel bar at the positioning mark, the bottom plate of the support and hanger main body is attached to the flat bottom formwork, and the iron nails are fixed to the bottom formwork through the lateral connecting plate. Repeat this step to install all the support hangers. Hanger body;

[0101] S23 Pouring concrete;

[0102] After the S24 concrete is dry, remove the bottom formwork;

[0103] S25 install the boom assembly;

[0104] S251 Tear off the adhesive film on the bottom plate of the main body of the support and hanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com