Construction method of ceramic tile seam beauty agent

A construction method and technology of beautifying agent, applied in the construction field of ceramic tile beautifying agent, can solve the problems of insufficient adhesion, insufficient hardness, fast yellowing speed, etc., and achieve long-term shedding and excellent yellowing resistance. , The effect of improving hardness and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

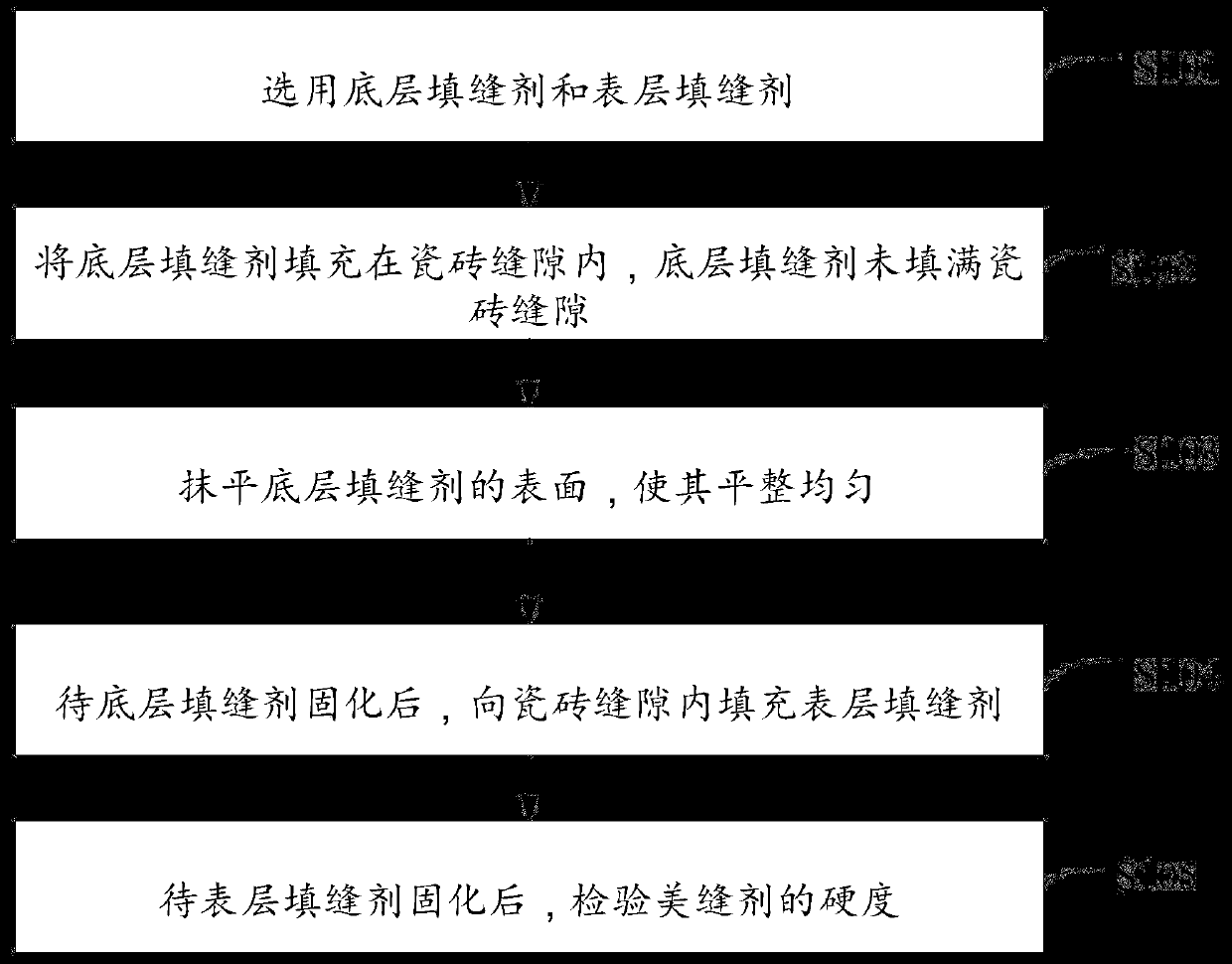

[0030] For the technical problems described in the background technology section, such as figure 1 As shown, the construction method of the tile beautifying agent provided by the application comprises the following steps:

[0031] S101: Select the base sealant and surface sealant.

[0032] In the embodiment of this application, the water-based emulsion and filler of the bottom sealant are selected; the glass transition temperature of the water-based emulsion is between 30 and 70 ° C, and the glass transition of the water-based emulsion is relatively high, so that the bottom filling after curing The hardness and adhesion of the joint agent are high. In addition, the filler in the base sealant is also conducive to improving the hardness and adhesion of the cured base sealant, thereby solving the problem of the beautifying agent falling off after a long time, and realizing the long-term firmness of the beautifying agent.

[0033] As a specific example of the present application...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com