Deep sea ore lifting pump structure and control method thereof

A control method and deep-sea technology, applied in the field of ore pumps, can solve problems such as the service life of flow channels that are easy to be blocked, the wear resistance of blocked flow parts, and poor wear resistance performance, and achieve poor wear resistance, sufficient transmission power, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

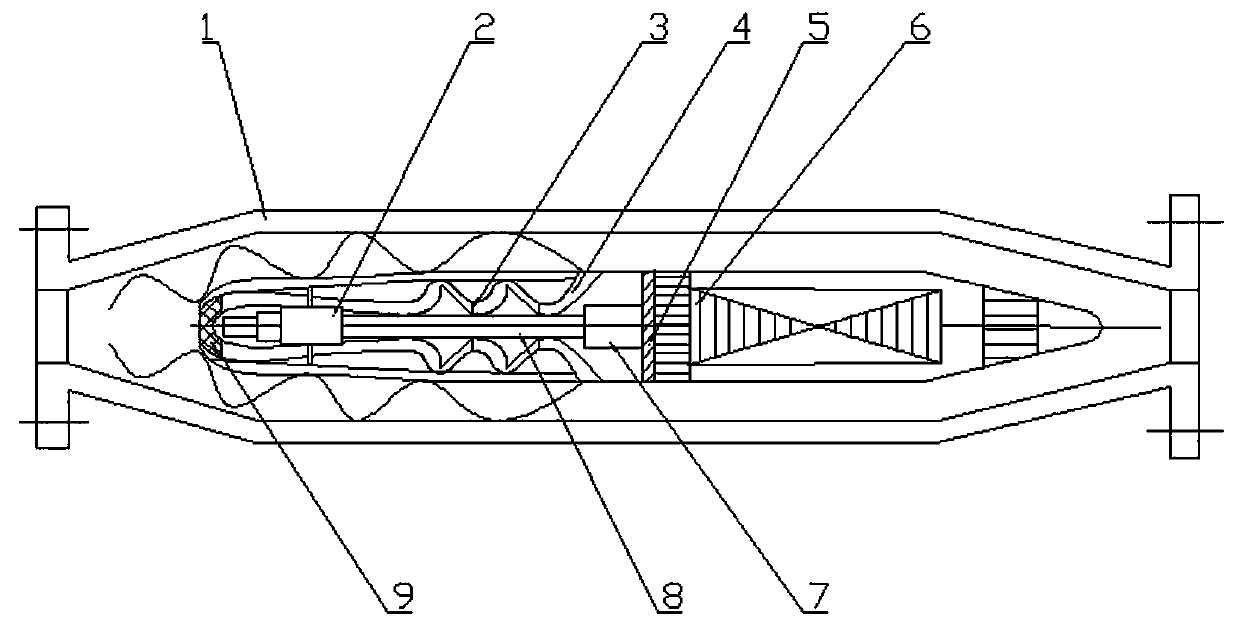

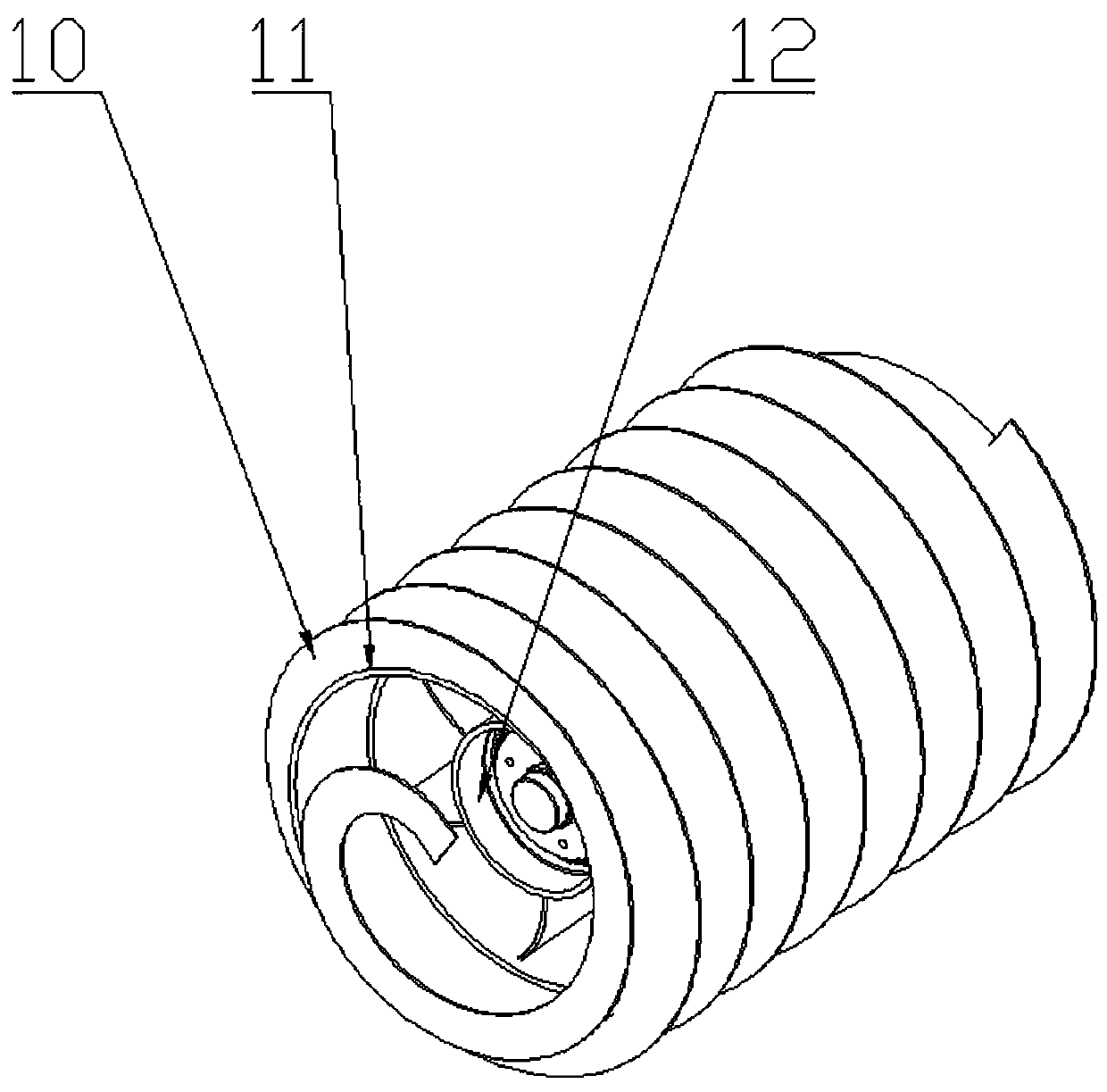

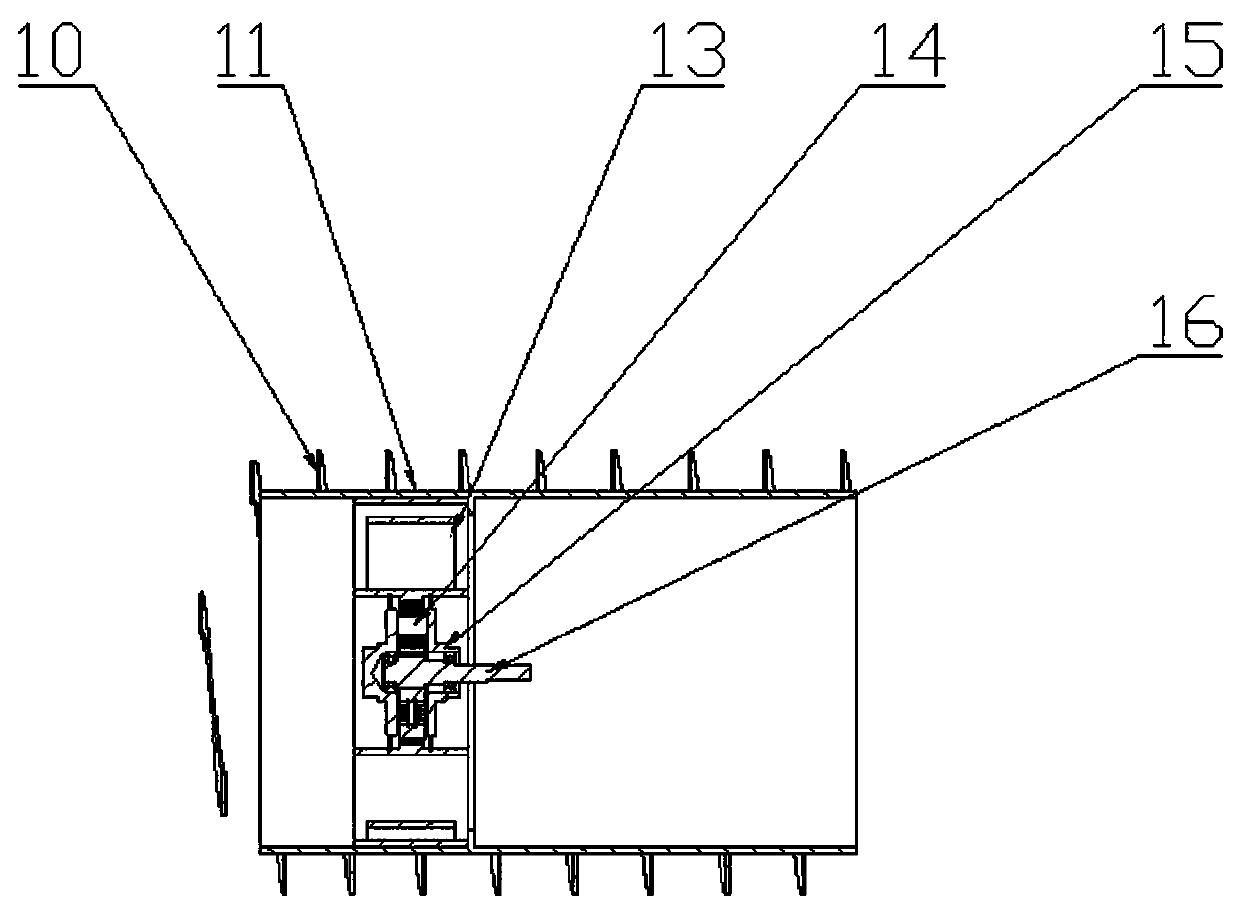

[0030] Example: such as Figure 1-7 As shown, a deep-sea mining pump structure includes a mining pump casing 1, a high-speed shaft 8 is arranged in the casing 1 of the mining pump, and a high-speed shaft is arranged between the rear end of the high-speed shaft 8 and the casing 1 of the mining pump. The driving motor 6 of the mining pump with 8-phase spline type snap-in limit socket, the shaft sleeve flange 7 is arranged between the driving motor 6 of the mining pump and the high-speed shaft 8, and the shaft sleeve flange 7 is connected with the driving shaft of the mining pump. A thrust balance frame 5 is provided between the motors 6 . A split drive mechanism 2 is provided between the front end of the high-speed shaft 8 and the casing 1 of the ore pump, and a fine-grain fluid tunnel 4 is provided between the split-flow drive mechanism 2 and the high-speed shaft 8. The fine-grain fluid tunnel 4 is provided with 3 groups of 5 pieces and The high-speed shaft 8 phases limit and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com