Permanent magnet coupling buffer protector

A technology of permanent magnet coupling and protector, used in permanent magnet clutches/brakes, clutches, automatic clutches, etc., can solve the problems of ineffective protection of high-speed gearboxes, difficulty in installation, maintenance, and thinning of friction lining loss. , to achieve the effect of reducing maintenance costs, eliminating torsional vibration, eliminating impact load and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

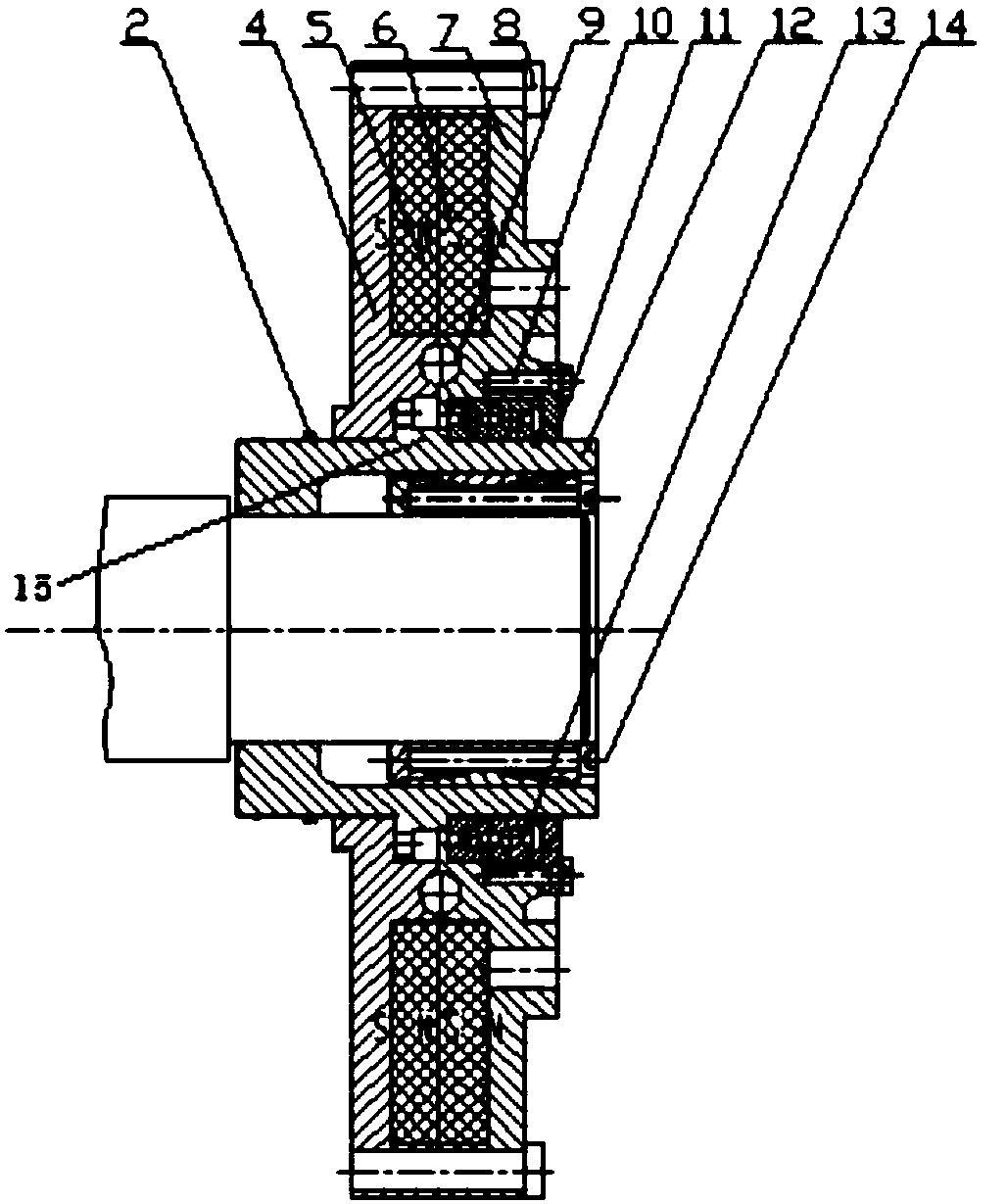

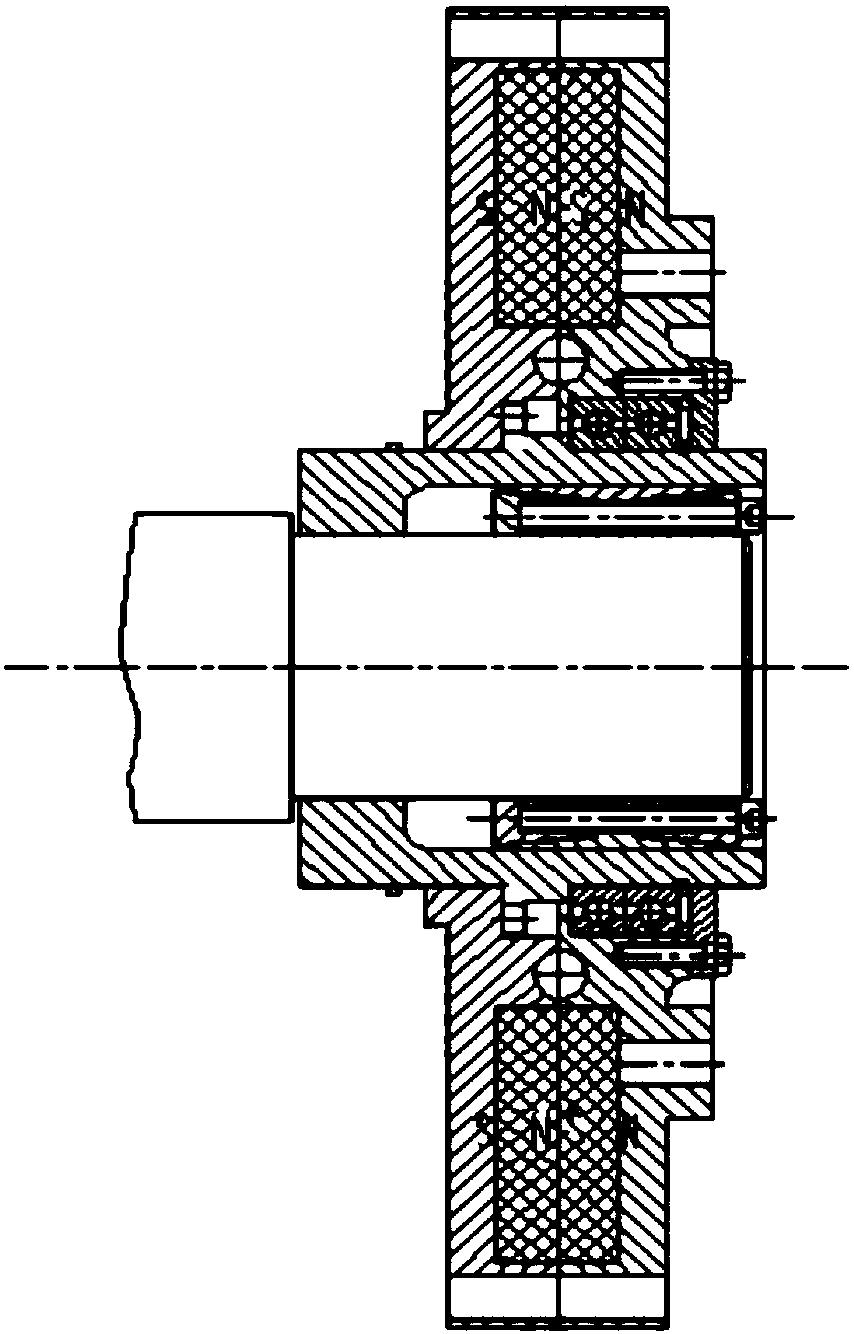

[0055] Such as Figure 1-5 Shown is a wind power permanent magnetic coupling buffer protector according to the first preferred embodiment of the present disclosure.

[0056] figure 1 It is a structural schematic diagram of the present disclosure. The wind power permanent magnet coupling buffer protector includes a limit stop ring 2, a driven plate 4, a driven permanent magnet 5, an active permanent magnet 6, an active plate 7, a linkage pin 8, and a marble 9 , Connecting bolts 10, bearing end cap 11, bushing 12, bearing 13, expansion sleeve 14, middle raised part 15.

[0057] The driving disk 7 is connected to the driving end (such as the output shaft of the speed-increasing gearbox), and the active permanent magnet 6 is fixedly installed on the driving disk. The magnetization direction of the permanent magnet is perpendicular to the axial direction, and the fixed installation form of the permanent magnet is N, S Staggered. A driven permanent magnet 5 is installed on the co...

Embodiment 2

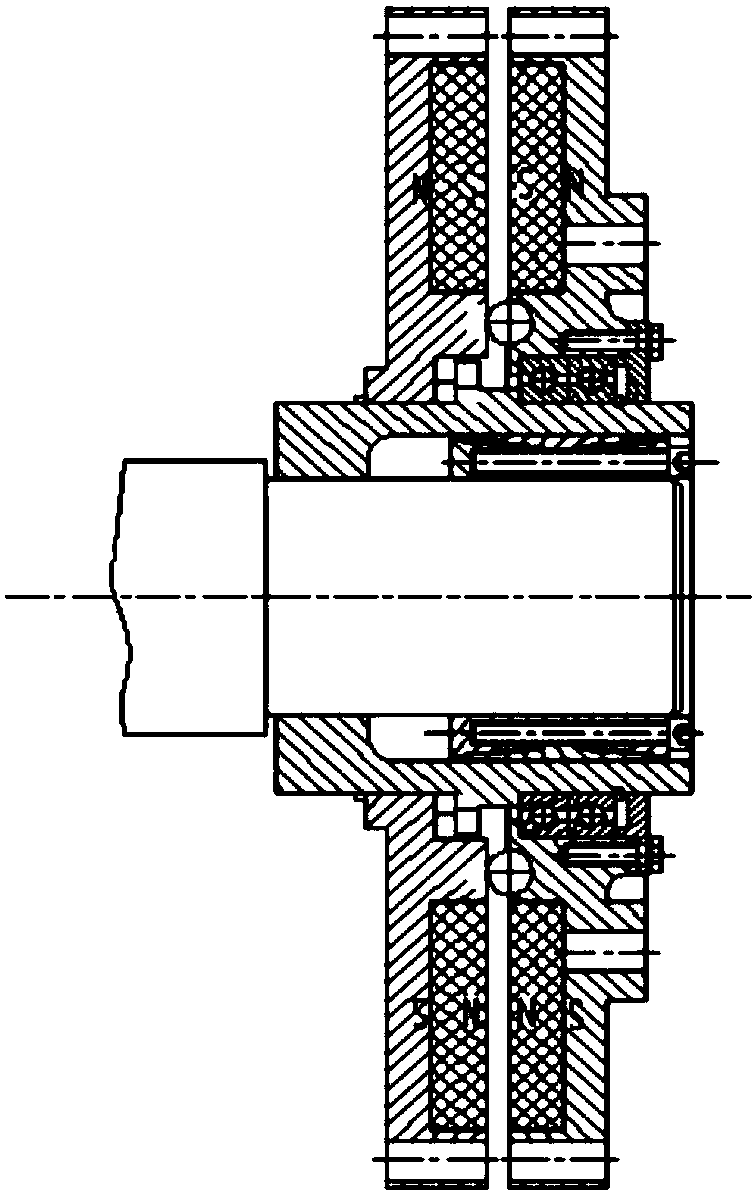

[0072] The specific implementation manner of the present disclosure can also be the second preferred wind power permanent magnetic coupling buffer protector. The difference between it and the previous embodiment is that the meshing between the driven disc 4 and the bushing 12 of this embodiment adopts the face tooth meshing method, and bevel gears are respectively arranged on the contacting end faces of the driven disc 4 and the bushing 12, such as Figure 6 As shown, it is the structural form of bevel gear shaft intersection angle Σ=180°, and the number of teeth is n times the number of driven permanent magnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com