Exploding foil integrated chip comprising energetic flyer

A technology of integrated chips and explosive foils, applied in the field of miniature low-energy ignition or detonation devices, can solve the problems of limited weapon systems, achieve the effects of reducing preparation costs, reducing ignition energy, and enhancing ignition or detonation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

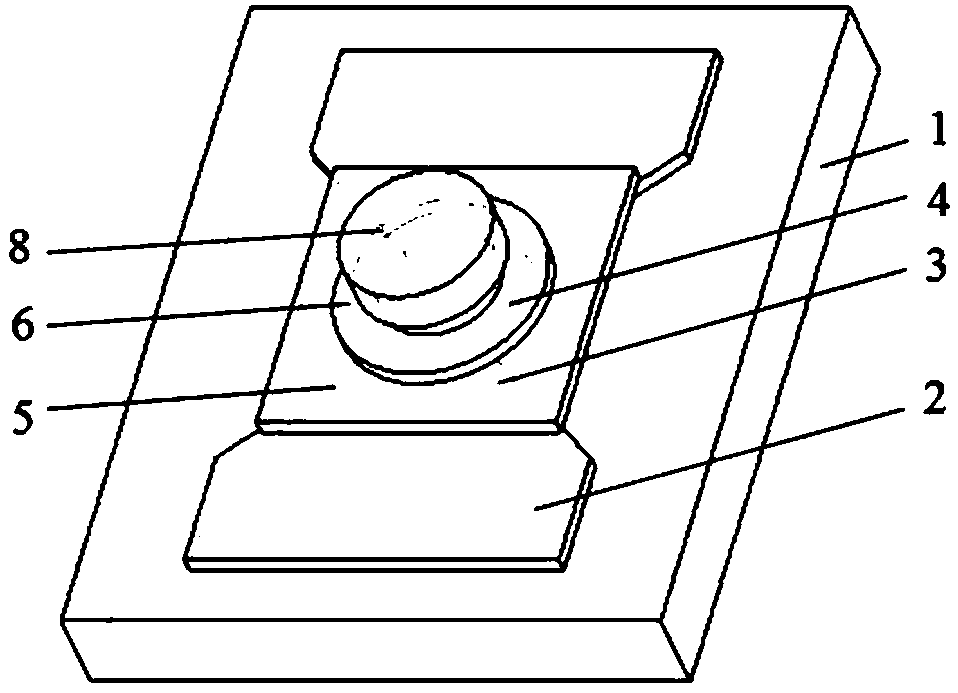

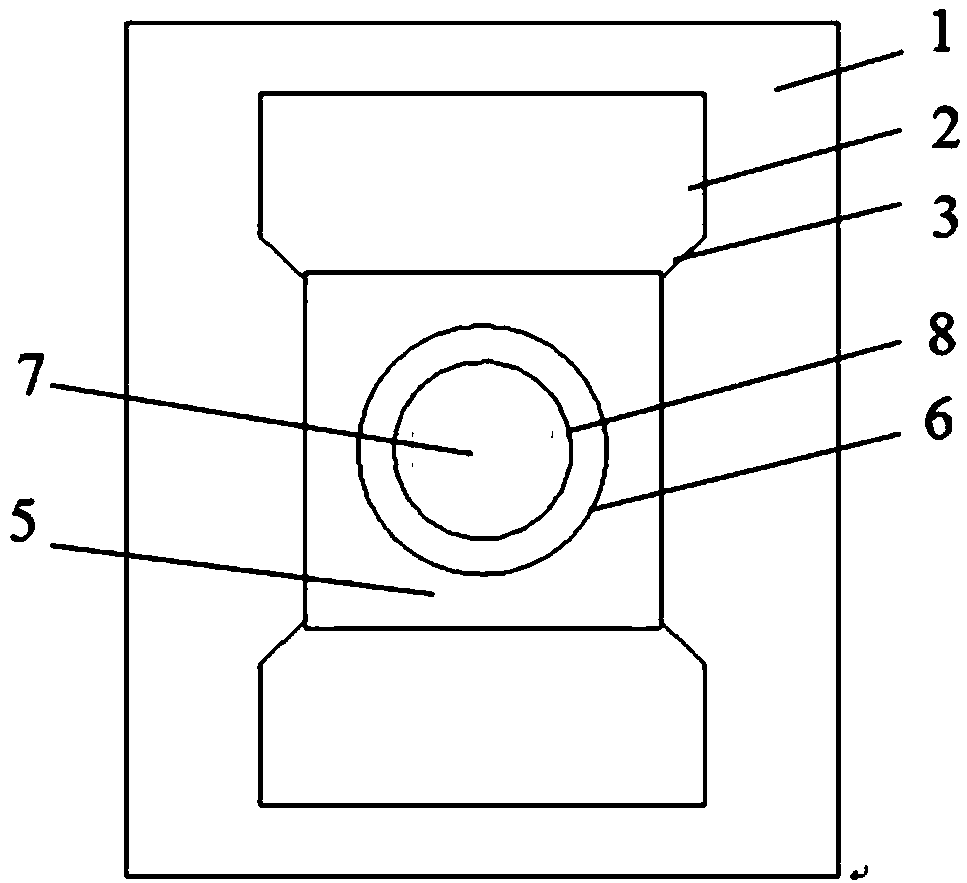

[0031] In this implementation case, an explosive foil detonation system is designed on the basis of the explosive foil integrated chip unit, combined with image 3 and Figure 4, including the following steps NOTE: image 3 The left and right pictures in a-3f are the front view and top view of the manufacturing process, respectively:

[0032] first step, see image 3 a, for 50.8mm long x 50.8mm wide x 0.86mm high Al 2 o 3 The surface of the ceramic substrate 1 is cleaned.

[0033] The second step, see image 3 b, Al metal layer is deposited on the surface of ceramic base substrate 1 by photolithography, lift-off process and magnetron sputtering process to form pad 2, transition region 3 and bridge foil 4. The relevant dimensions are: the width of pad 2 is 7.5mm; the distance from bridge foil 4 to pad 2 is about 5mm; the size of bridge foil is 0.3mm×0.3mm×3.6μm; The transition area 3 is connected; in order to facilitate welding and conduction, a 100nm Au layer is deposited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com