Array element position calibration measurement point interval optimization method of hydroacoustic positioning and navigation system

An array element location and navigation system technology, applied in radio wave measurement systems, instruments, etc., can solve the problems of small calculation amount, large model mismatch error, ignoring model mismatch problems, etc., to eliminate model mismatch errors and improve Effects of Calibration Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

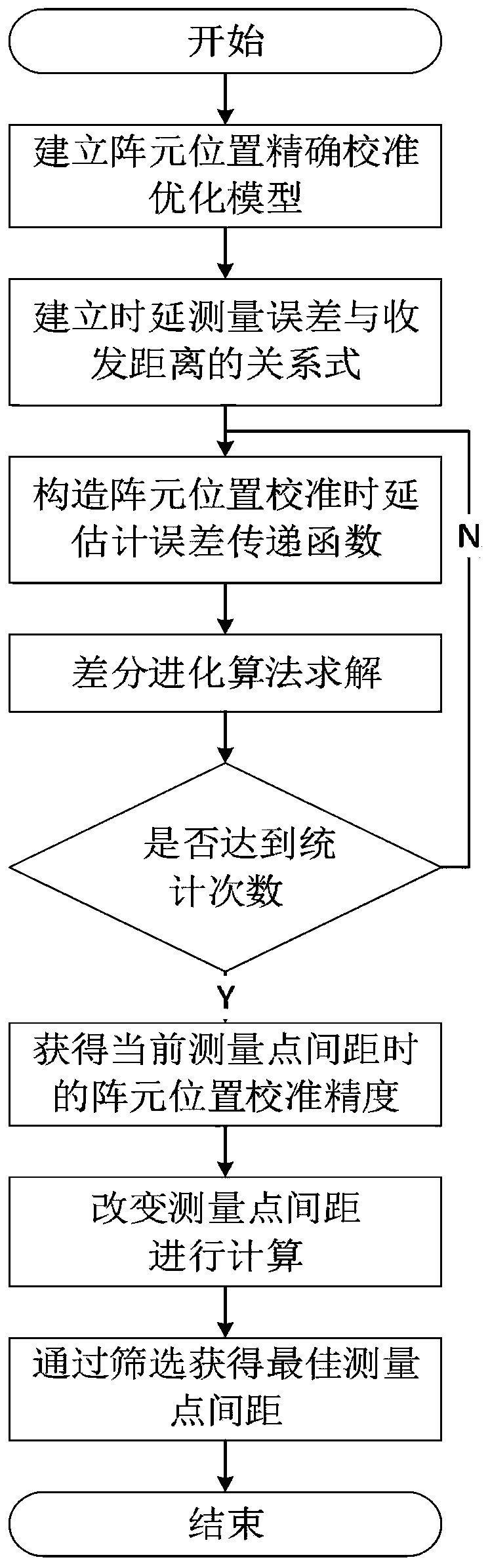

[0044] The present invention provides a method for optimizing the distance between array element position calibration and measurement points of an underwater acoustic positioning navigation system. The method includes the following steps:

[0045] Step 1: According to the measurement position coordinates of the survey ship, establish an optimization model for accurate calibration of the array element position;

[0046] Step 2: Establish the relationship between the time delay measurement error and the sending and receiving distance function;

[0047] Step 3: Construct the error transfer function of the array element position calibration delay measurement, and use the differential evolution algorithm to solve the element position calibration delay measurement error transfer function to obtain the position result and error of the array element to be measured;

[0048] Step 4: Use statistical methods to obtain the calibration accuracy of the array element position;

[0049] Step...

specific Embodiment 2

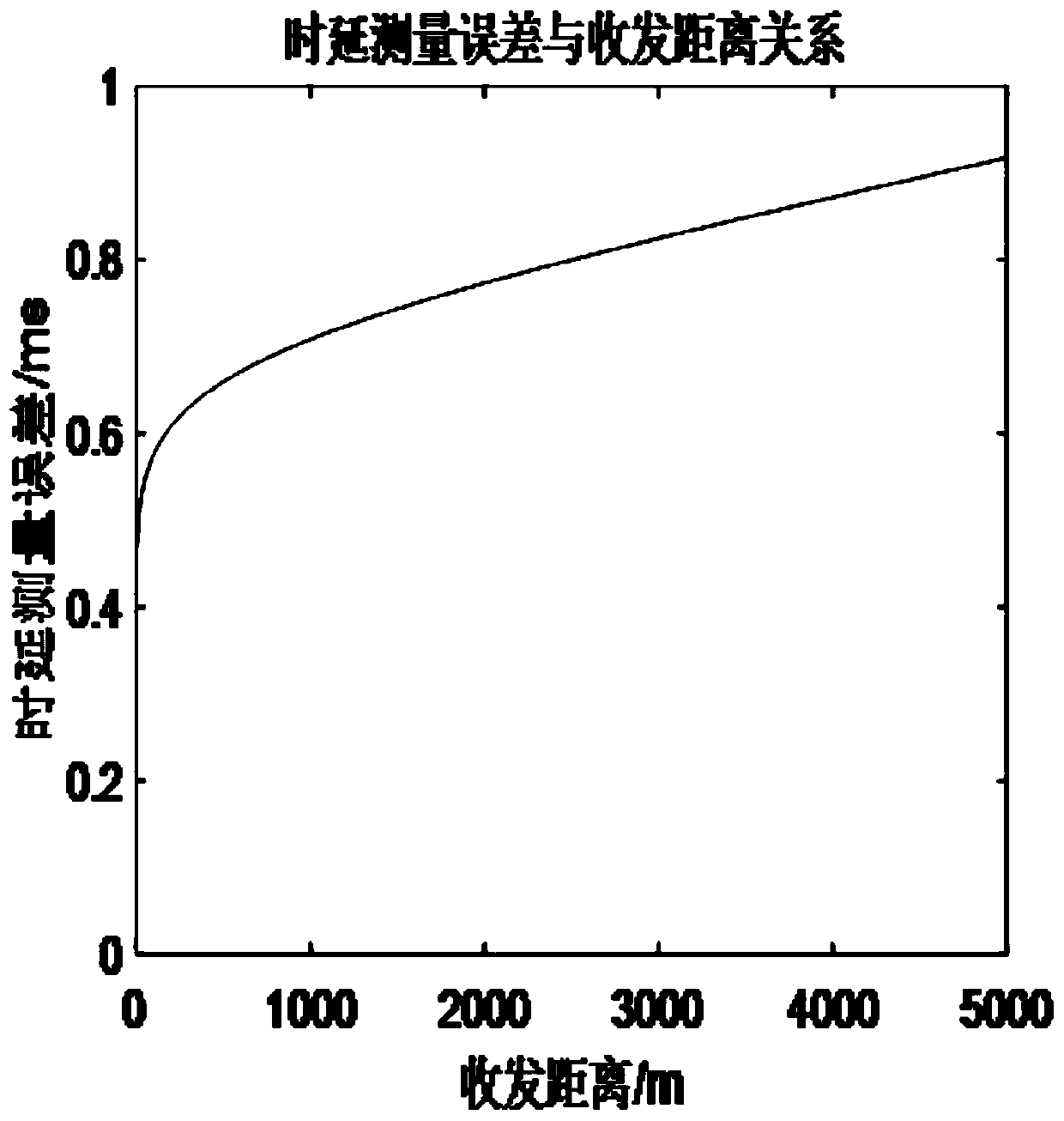

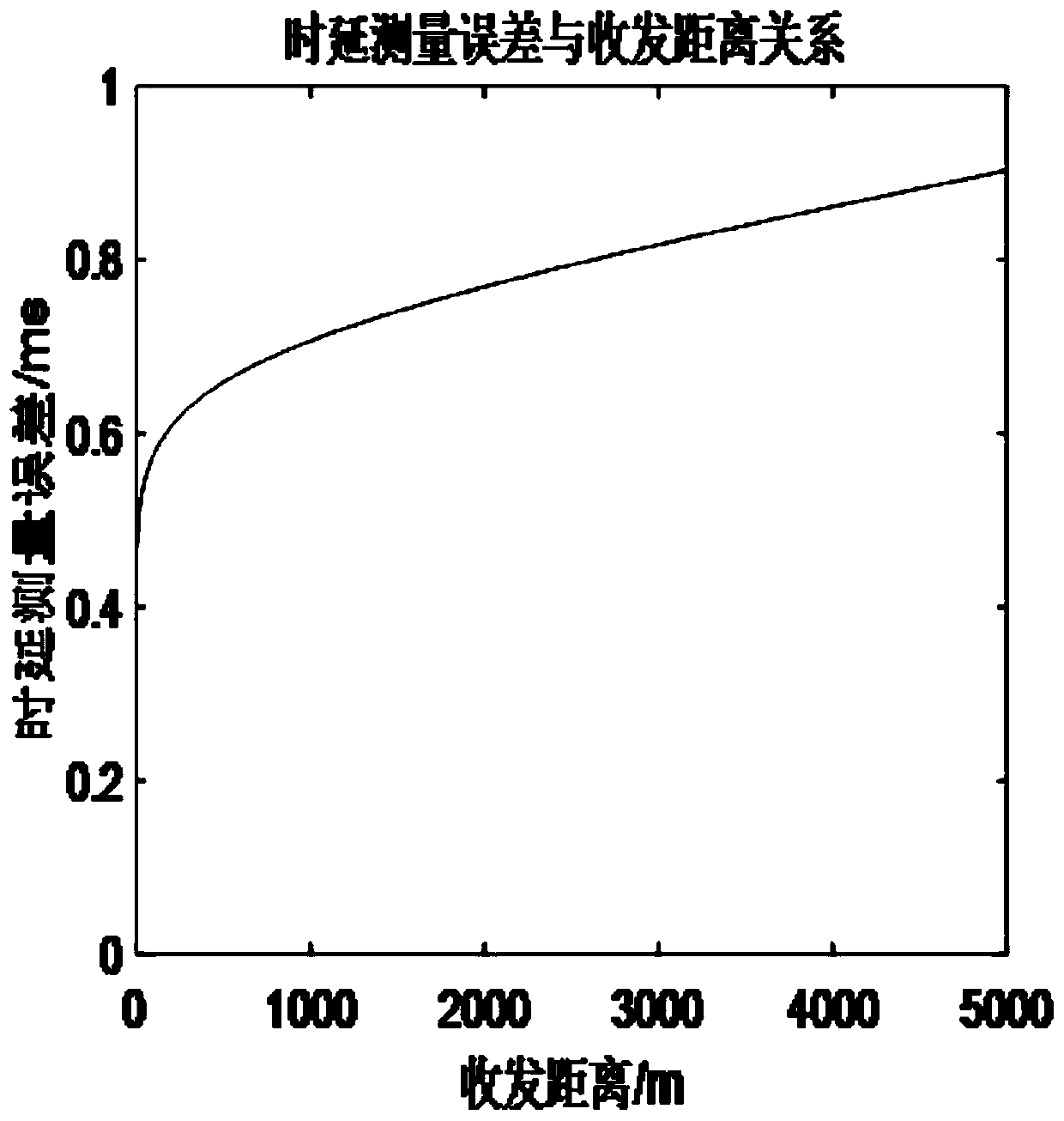

[0073] Firstly, the relationship between the delay measurement error of 10.5kHz and 11.5kHz signals and the distance between sending and receiving is given, as shown in figure 2 and image 3 shown. It can be seen from the figure that the delay measurement error increases with the increase of the transmitting and receiving distance, and the signal delay measurement error increases rapidly with the increase of the transmitting and receiving distance in the first 2000m, and then the growth trend tends to be flat.

[0074] Then the parameters are given as follows: the sound source of the measuring ship enters the water 6m, the moving speed of the measuring ship is 8m / s, the frequency of the interrogation sound signal is 10.5kHz, the distance between the measuring points is L, and the coordinates of the measuring points are respectively The position of the array element to be tested is The response signal frequency is 11.5kHz; the delay measurement error is related to the send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com