Preparation method of monocrystal piezoelectric film heterogeneous substrate

A heterogeneous substrate, single crystal piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of huge gap in thermal expansion coefficient, support substrate fragmentation, etc. Achieve the effect of avoiding the split problem and solving the thermal mismatch problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

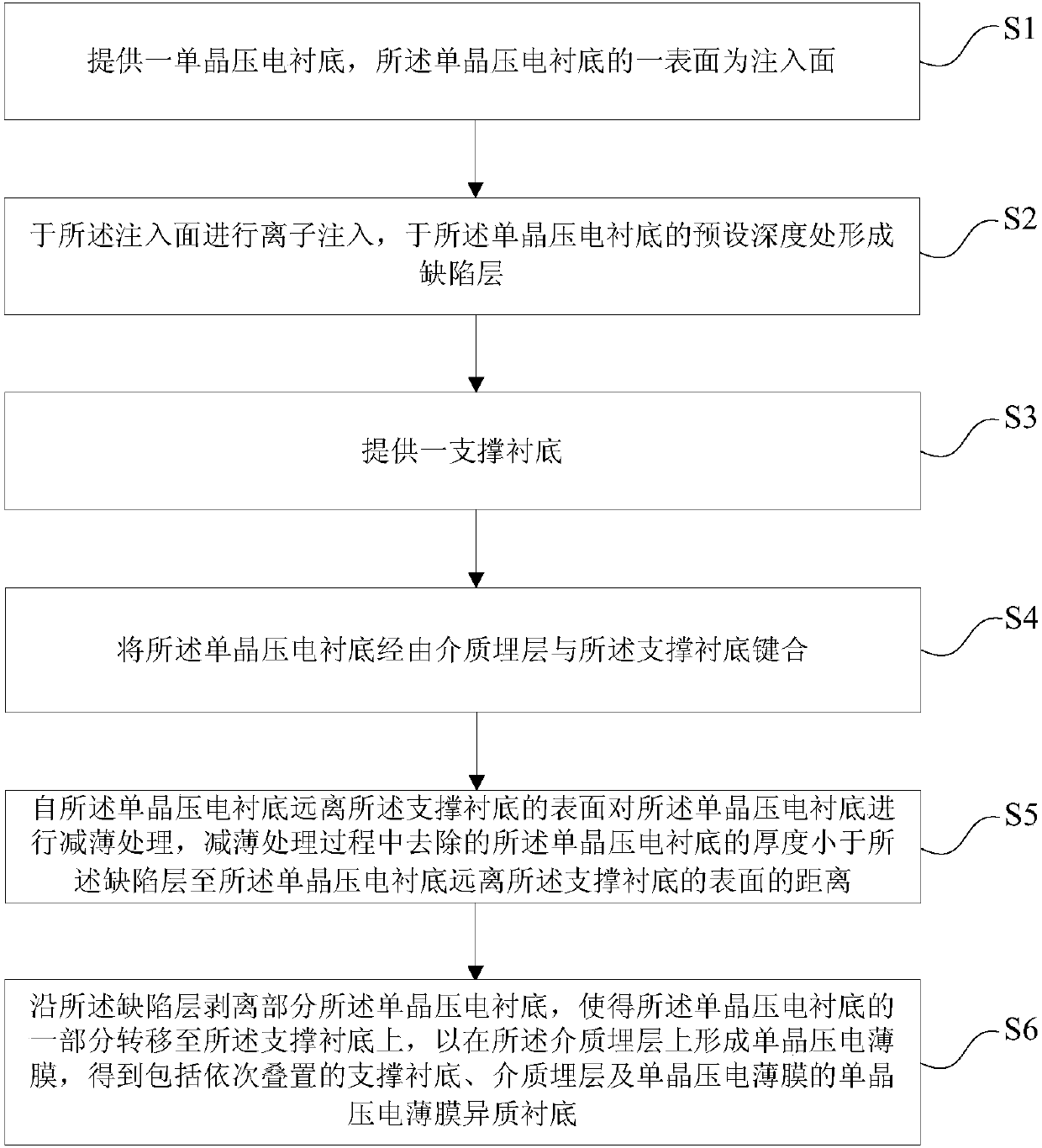

[0049] see figure 1 , the present invention provides a method for preparing a single crystal piezoelectric thin film heterogeneous substrate, the preparation method of the single crystal piezoelectric thin film heterogeneous substrate comprises the following steps:

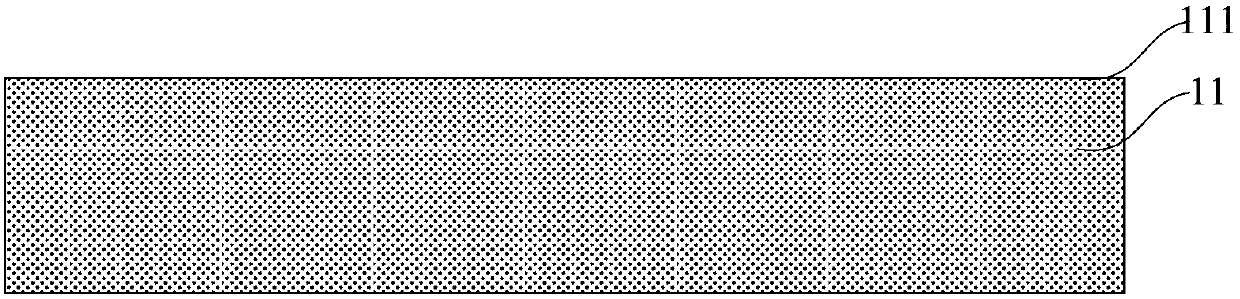

[0050] 1) providing a single crystal piezoelectric substrate, one surface of the single crystal piezoelectric substrate is the injection surface;

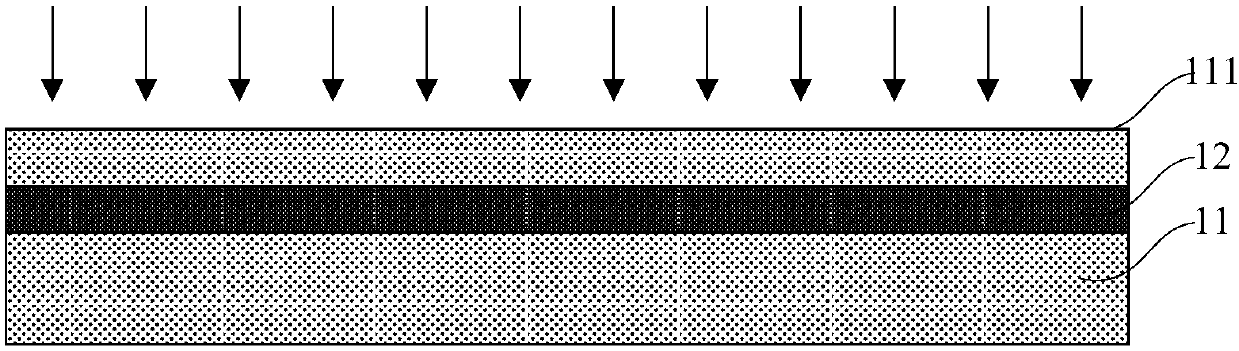

[0051] 2) performing ion implantation on the implanted surface to form a defect layer at a predetermined depth of the single crystal piezoelectric substrate;

[0052] 3) providing a supporting substrate;

[0053] 4) bonding the single crystal piezoelectric substrate to the supporting substrate via a dielectric buried layer;

[0054] 5) Thinning the single crystal piezoelectric substrate from the surface of the single crystal piezoelectric substrate away from the support substrate, and reducing the thickness of the single crystal piezoelectric substrate removed during...

Embodiment 2

[0089] see Figure 12 , the present invention also provides a method for preparing a heterogeneous substrate of a single crystal piezoelectric film, the method for preparing a heterogeneous substrate of a single crystal piezoelectric film described in this embodiment is the same The preparation method of the electric thin film heterogeneous substrate is roughly the same, the difference between the two is that this implementation includes the step of forming the high-sonic material layer 15 on the basis of the first embodiment.

[0090] It should be noted that when the buried dielectric layer 14 is formed on the supporting substrate 13, before the buried dielectric layer 14 is formed on the supporting substrate 13, the buried dielectric layer 14 is formed on the surface of the supporting substrate 13. The high-sonic material layer 15, the dielectric buried layer 14 is formed on the surface of the high-sonic material layer 15; when the dielectric buried layer 14 is formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com