Preparation method and product of ceramic material component with adjustable thermal expansion

A ceramic material and thermal expansion technology, applied in the field of preparation of ceramic material components, can solve the problems of inability to adjust, inability to achieve zero thermal expansion and negative thermal expansion, limited application, etc., and achieve the effect of simple preparation method, easy operation, and high-precision molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

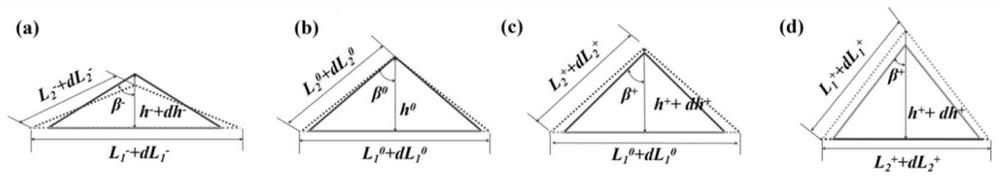

Method used

Image

Examples

Embodiment 1

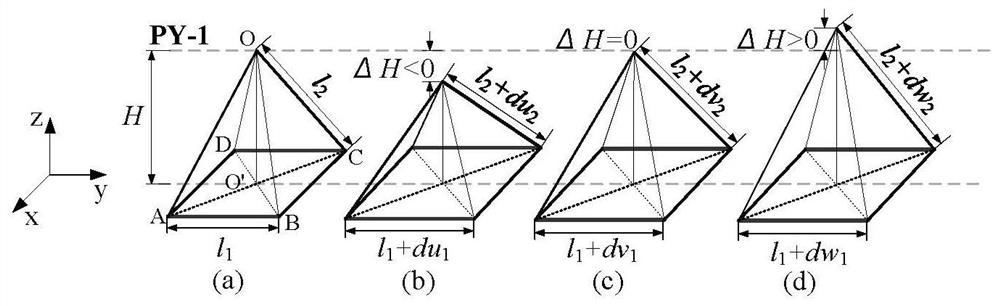

[0055] (1) Design a two-dimensional isosceles triangular structure ceramic material component with zirconia as the base and alumina as the hypotenuse, then α in formula (1) b =12.78×10 -6 / °C,α h =8.2×10 -6 / °C, according to formula (1), the relationship between the half-vertex angle and the equivalent thermal expansion coefficient in the height direction can be obtained, such as image 3 shown. Select the design value as 0×10 -6 / °C, and the half top angle is 53.69°.

[0056] (2) Prepare 100mL of alumina slurry, wherein the volume content of alumina ceramic powder is 55vol.%, the content of photosensitive resin is 45vol.%, and the amount of polymer dispersant KOS110 is 2wt% of the amount of alumina ceramic powder. The amount of initiator TPO added is 1wt% of the amount of photosensitive resin, the amount of sintering aid titanium dioxide is 3wt% of the amount of alumina ceramic powder, and the amount of magnesium oxide is 1wt% of the amount of alumina ceramic powder. Aft...

Embodiment 2

[0062] (1) Design a two-dimensional isosceles triangular structure ceramic material component with zirconia as the base and alumina as the hypotenuse, according to image 3 shown. Select the design value as -16.03×10 -6 / °C, and the half top angle is 66.5°.

[0063] (2) Prepare 100mL of alumina slurry, wherein the volume content of alumina ceramic powder is 55vol.%, the content of photosensitive resin is 45vol.%, and the amount of polymer dispersant KOS110 is 2wt% of the amount of alumina ceramic powder. The amount of initiator TPO added is 2wt% of the amount of photosensitive resin, the amount of sintering aid titanium dioxide is 3wt% of the amount of alumina ceramic powder, and the amount of magnesium oxide is 1wt% of the amount of alumina ceramic powder. After 14 hours of ball milling, the oxide Aluminum paste, denoted as A.

[0064] (3) Prepare 100mL of zirconia slurry, wherein the volume content of zirconia ceramic powder is 50vol.%, the content of photosensitive resin...

Embodiment 3

[0069] (1) Design a two-dimensional isosceles triangular structure ceramic material component with alumina as the base and silicon carbide as the hypotenuse, then α in formula (1) b =8.2×10 -6 / °C,α h =2.6×10 -6 / °C, according to the formula (1), the relationship between the half top angle and the equivalent thermal expansion can be obtained, when the design value is selected as 0.73×10 -6 / °C, the half top angle is 30°.

[0070] (2) Prepare 100mL of alumina slurry, wherein the volume content of alumina ceramic powder is 55vol.%, the content of photosensitive resin is 45vol.%, and the amount of polymer dispersant KOS110 is 3wt% of the amount of alumina ceramic powder. The addition amount of initiator TPO is 2wt% of the amount of photosensitive resin, the sintering aid titanium dioxide is 2wt% of the amount of alumina ceramic powder, and the amount of magnesium oxide is 2wt% of the amount of alumina ceramic powder. The alumina slurry can be obtained after ball milling for 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com